I'm sure this has come up before, but I have some questions about hand laid track vs. what is commercially available. I'm also sure that opinions vary greatly, but here are my questions:

- Initial material cost: Is the initial cost for raw materials in rail, ties and spikes less expense than what is available pre-packaged?

- What is the relative skill level required to bend rail and lay track by hand? I have a standards gauge so that isn't an issue.

- Once one becomes somewhat proficient, what kind of time investment is involved? I still have close to 20 years until retirement if I'm so lucky and a nearly 9 year old so time is an issue.

- How hard it is to build turnouts? I've seen the HO gauge metal templates. Are there comparable O scale ones?

- In your experience how happy are you with your decision either way?

While I don't have space for my 2 rail layout yet, I will likely get to building some modules when the weather drops below 100 in mid October. The urge is there to finally get started so I can finally run my collection of 2 rail O.

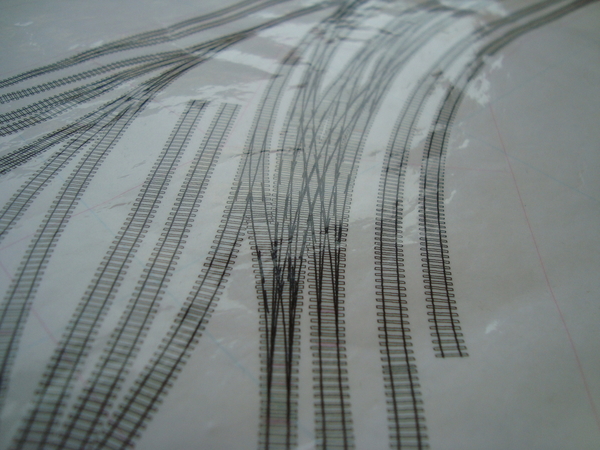

This an image of the look I'm going for on the track even if it is code 172. I got this as a gift from a friend who disassembled a layout in 16" sections. I love the look even if the rails are too robust for my tastes. Time has been a friend to look of this track.

Thanks!