It should make a few laps around your layout with that train... something still needs some TLC.

Drag is the enemy of windup trains. Anything that causes friction between the moving parts of the motor or wheels must be addressed. Sometimes it can be difficult to figure out what the problem is. Look for carpet fibers or hair wound up on the axles or shafts in the motor. It can get wrapped up between the wheels and sideplates, causing quite a bit of drag. I know you have cleaned and oiled the motor already - and it seems to work normally in the first video of the motor that you posted back on the 7th - but I am wondering about the back wheels on the motor. The one wheel appears to be a bit close to the sideplate, so make sure that it can't rub and drag, too. If the wheels have been loose and repaired (a common issue with Marx stamped steel wheels of this vintage) they can be wide on gauge and cause excessive drag between the flanges and rails. Another thing that can cause drag is the sparker. Sometimes the flap that holds the flint will be bent so that when the motor is mounted in the shell, the tab is pushed up against the inside of the top of the boiler, causing a severe loss of power. Try running and trouble shooting just the motor outside the shell - I think it should easily make at least 4 or 5 laps around your track by itself without any problem. If it runs OK, try putting it in the shell and make another run. In addition to the sparker flap, I've also seen the rear motor mount bent so it contacts and drags on a rear wheel.

If you can get the loco running a few laps around the layout by itself, it will be time to turn your attention to the cars. The tin frames are easily bent out of shape, and can drag against the wheels. Any little drag that might seem insignificant to an electric train can cause a big problem with a windup train. Of course, the axles need to be oiled where they pass through the frame, too.

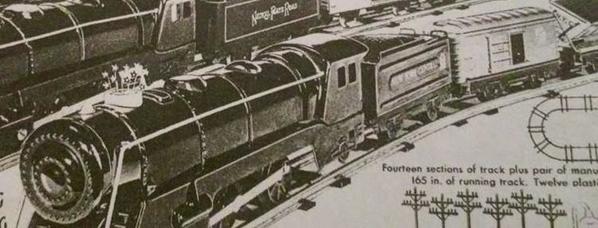

I looked through my videos, trying to find something to give you an idea of what to expect from your locomotive, but apparently I don't make many videos of my off-the-shelf Marx windups! But, here are a couple for your amusement...

First, the Marx Clockwork Train Race. Not really a race, but will give you an idea of how long a locomotive should run if it is just pulling a tender:

Next, a video of a couple of Marx locos converted from electric to windup. The motors themselves are stock, so it will give you an idea of what kind of performance to expect from a typical Marx windup train:

Finally, a video of some of my modified Marx windup locomotives; "Windup Trains on Steroids". Proof that windup trains don't have to be weaklings: