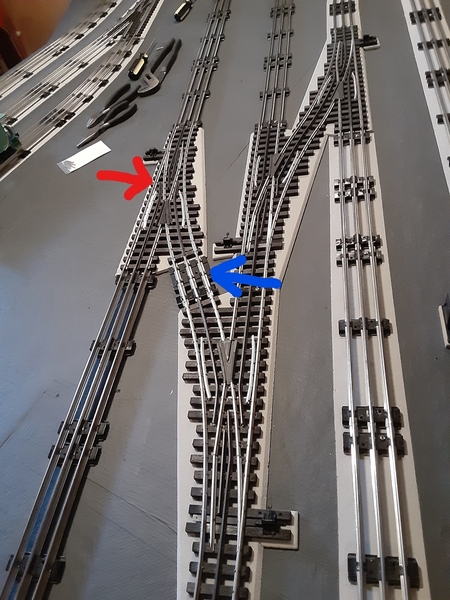

Track power was lost when entering the curved section of the switch with the red arrow in the photo below. When I put a 5" track between that switch and the one adjoining it , track power was restored throughout the switch and tracks adjoining it. However, when I put 2" transition piece between them, track power was again lost. So, I tried a 3" section and got track power back (blue arrow in photo). Can anyone tell me a) why no track power in the first place and b) a longer transition piece rather than a shorter one restored track power? Thanks. Doug

Replies sorted oldest to newest

@postmastermc posted:Track power was lost when entering the curved section of the switch with the red arrow in the photo below. When I put a 5" track between that switch and the one adjoining it , track power was restored throughout the switch and tracks adjoining it. However, when I put 2" transition piece between them, track power was again lost. So, I tried a 3" section and got track power back (blue arrow in photo). Can anyone tell me a) why no track power in the first place and b) a longer transition piece rather than a shorter one restored track power? Thanks. Doug

This does seem like an odd issue. It might be helpful if you were to provide more information about how and where you're supplying power to the 2 parallel tracks shown in the picture as well as how the individual parts of the switches are wired to the track power source.

Possibly, you are just getting unlucky with the spacing of the dead spots in your switches lining up precisely with the 3rd rail collector rollers on your engine. That is the first thing to check, before chasing after wiring / electrical problems.

After roller spacing, the next thing to look at is dirty track. The black center rail on these can be quite dirty when new. It may be that your engine goes through with the fitter in place because it can bridge the dirty spot as long as it has at least one collector roller on the nice, tin-plated fitter piece.

With the switch in question, is there continuous power on the curve portion to the other switch and is there an insulating pin on the straight piece of the switch before the curve? What I wondering is could the power for the curve be coming from the other switch side, and when you change the geometry with the different size transition pieces it is breaking that path (just a wild guess).

The other thing is as the other poster said, how is the switch wired? Some switches don't guarantee through power, you may need to run power to the curve rail to guarantee having power through there. Agree with the other poster, be good to know how the switch is wired.

just a question noting that I know I'm not answering your issue: why aren't you having the same issue on the other pair of crossover switches that are visible in the image? Is the spacing piece the same?

walt

These are all Ross pre-wired switches. I tried the same switch in a different location on the layout and had no issues. The only solution so far has been to add the appropriate length of transition track between switches. No big deal, but it would be nice to know what caused the problem. Maybe Steve at Ross has the answer.

Walt, there's no spacers between the other switches and no problems there.

Doug

You haven’t mentioned using a multimeter to verify all parts of the non working pair has track power. I’d start there.

I had a similar thing going on with a set of Lionel automatic switches. I finally just pulled it all apart, took a drill bit of the proper size and by hand "reamed" the insides of the rail end holes, on each rail end in the sequence, then installed shiny new track pins and brand new fiber pins in the proper locations, the put it all back together and crimped really really hard every connection point, on both sides of the rail connections.

Then I cleaned the heck out of the track, and vacuumed the track sections and turn outs long and hard.

The problem went away.

Also, are you using the same engine, and running it in the same direction every time you test the track? If so, it is highly possible that you have an engine issue, not a connection issue. Trying running a few of your longest locomotives over it, and see what happens.

Why? I just got a brand new, NIB, RMT Beep. It runs around all of my layout without any problems whatsoever, EXCEPT, that when it runs over one particular switch, in one direction only, it stops DEAD! None of my other engines, including my other BEEP do this. And, if I just lift the BEEP up and turn the engine around, so that the rear end of the engine goes over that switch first, in that same direction, then it glides over it with no problem whatsoever.

When it was running and passed over the switch and stopped yesterday, I left it where it was, and got down next to it and looked underneath the engine with a magnifying glass. One of the rollers is sitting on the plastic part of the frog, and the other is barely grazing the top of the electrified rail behind it. The gap between the roller and rail is thinner than a human hair and almost imperceptible. So, it is just a mechanical issue. Either the middle rail of the switch is out of spec, or that roller is out of spec, or both. If I lightly touch the side of the engine, so that it barely rocks to one side, it takes off.

Not worth worrying about. I'll just make sure I never try to run that BEEP, in the bad direction, over that particular switch.

Or, maybe, if I get brave, I might try to lay a really light coat of solder on top of that rail, to raise the surface slightly, so that it touches the roller better.

Hope these ideas may help.

Mannyrock