Well, you've already gotten to most suggestions I had wanted to make....and it looks like I finally got an attachment tool too, lol. (those photos are a week or two old now)

Oh, youve stumbled on one of my "whiney" posts. I had a young guy I was helping out causing me immense daily life pressures before I finally gave up on them and booted them to lifes curb. Food seemed to play a part as well; mom is alergic to "everything" it seems. I switched super markets for meat and began feeling better, and sleeping better as well.

My migraines were more "light show" than pain, and only lasted about a year or so around the height of my insomnia( which is still a pita, but I'm not going 4-6 days without sleep anymore either). Just once or twicetwi the last 2 years have I went four days without ANY sleep. There is a new migrane pill, I don't recall the name of at the moment but it's helping an aunt temendosly; I'll try to get the name.

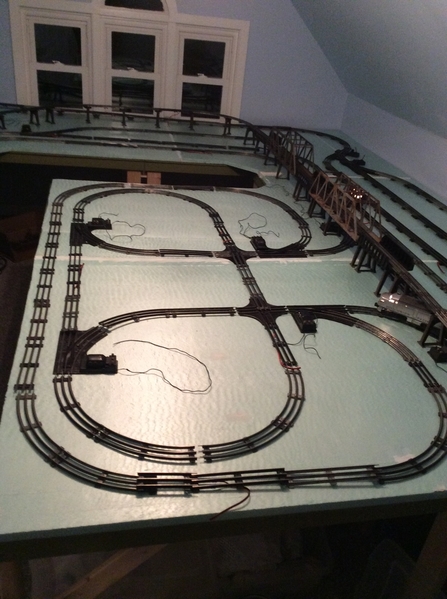

Can you use one clip to cover the level el, the others to cover the grade?

Or if the height difference is small, and you have opportunity, use an "D" with short clip, then "D" with tall clip, then "E" with short clip, then "E" with tall clip to spread the grade (lessen it). (note I think the height between letters changes slightly to provide for transition to grade...never measured that close though)

Adding a teardrop shape at the loop preceding the grade (and the other loop to make room for it) would help with consistency of throttle and any S turn issues too

.