Hi guys,

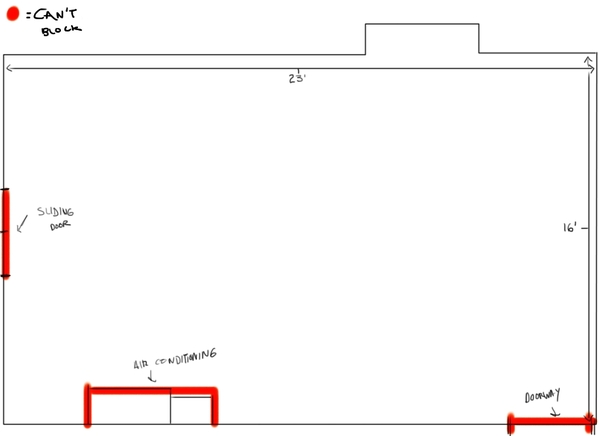

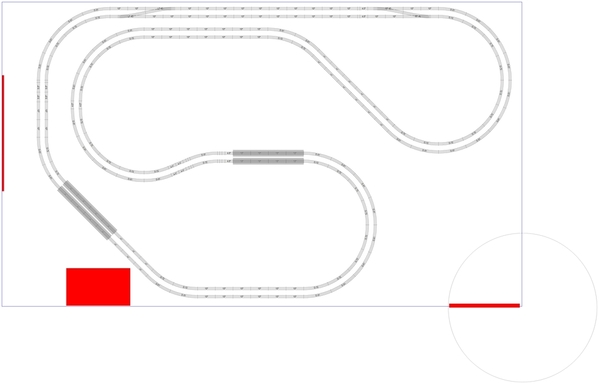

I am thinking of building a layout soon. I have measured the room in the basement, and it is 22' 6" x 15' 4", with an air-conditioning unit measuring at 24" x 37" offset towards the sliding door at the back wall. I would like to build a 'Folded Dogbone' track layout, but I need help with designing a track plan.

Thanks for the help,

Alex

- A minimum curve of O-72, so I can run larger engines/rolling stock

- If possible, a two-track mainline

- A passenger station

- Tunnel or a bridge

- Maybe a couple of sidings for some factories, etc.