I attempted to run a PS2 MTH MU set after a couple of years of storage. The engine came up on the remote, but at 2 SMPH the unit was off to the races. I stopped the engine and did a factory reset. The process deleted the engine, but when I attempted to "add" the remote read "Engine not found". There was some intermittent crackling sounds from the speaker. I noticed there was a 7-8 amp draw. I shut down the power and as I approached the engine I could smell that acrid burnt PCB odor. I took the shell off and immediately noticed the NiCd battery appeared to have a brown sugar type substance on and around the holder. The substance was not near the circuit boards. Inspecting the boards, there doesn't seem to be anything swollen or burnt.

1. Could the failure be caused due to a damaged battery?

2. Could a failure with the circuitry have cause the battery to rupture?

3. Would it be safe to swap out the battery, or would there be potential to ruin the good battery?

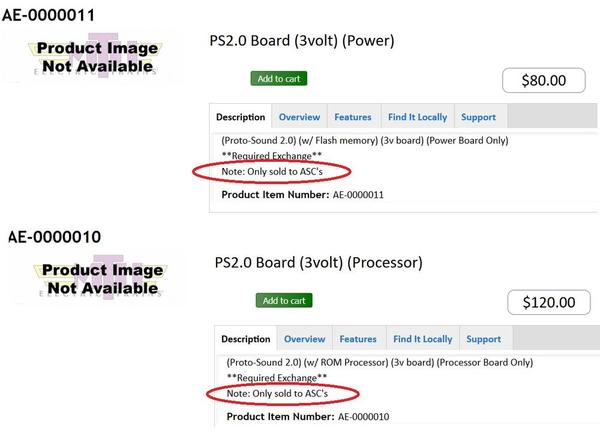

4. The IC's look modular. Could this be an under $100 repair?

As many can probably relate, the days of a $200 repair are over, being on retirement! If this problem sounds expensive, is there an inexpensive motor driver board, and if so, what would you suggest. Gutting and downgrading may be my only option.

Rich