Dad and I are moving along on the layout that we've been planning the past few months, and we've completed the benchwork and moved on to the top side.

Dad's old layout was always just Lionel tubular track screwed right into a piece of plywood. It's been like that since he was a kid, so I was trying to explain to him what homasote is and why members of this forum seem to recommend it as THE definitive surface to build on. However, it presents a bit of additional labor, as well as another couple hundred dollars of investment. Dad is skeptical of just about anything that he hasn't heard of before, so prior to giving me the OK to order 6 sheets of homasote and putting it on his Menards card, he wanted to see proof that it was going to be "worth it".

Although there are several advantages that forum members ascribe to homasote, the primary one (and the one dad is most interested in) is noise reduction. Especially since, upon installing our first piece of plywood on our new benchwork, dad was not exactly thrilled with how loud a little PW engine on an impromptu oval really was. If we were planning on running 3 trains simultaneously, this could get REALLY loud in our little concrete basement room.

So, we set off to make a definitive decision. Was homasote, at a cost of about $300 installed, going to be worth the time and effort for the benefit of reduced noise? Just how much noise reduction would we expect? If it was one dB(a), it wouldn't even be perceptible, and dad would balk at the cost. If it was three, then...maybe? six or more? That would be significant and maybe worth the expense.

Our experiment was simple. We built a temporary oval of 027 tubular track on the bare 1/2" plywood screwed directly to our actual benchwork in the train room. I downloaded a (paid) app for use with my Android that would suffice to measure sound pressure levels on the a-weighted spectrum (the spectrum that most affects human ears). Even if it wasn't calibrated, we would still be able to collect *difference* data that would be worthwhile. I installed an inexpensive microphone and hung the apparatus directly above the layout in a fixed location. Then we collected noise levels over 30 to 60 seconds for several runs. These runs included:

- Collecting a "baseline" data set of ambient noise levels (no TV, no yelling kids, etc).

- Running a PW Erie Alco engine alone around the loop at low, medium and high speeds

- Attaching four cars to the engine and running the train around the loop at low, medium and high speeds

- Substituting the PW Erie Alco with a modern Williams electronic F-Unit and running the train at several speeds

- Removing the cars and running the Williams loco alone

We then took up the loop of track, installed and fastened a 1/2" piece of homasote using drywall screws through the homasote to the plywood, then reinstalled the exact same track oval using the exact same 1/2" #4 screws in the exact same holes as the ones we used to anchor the track to the plywood in the previous run. This meant that the track was ONLY fastened to the homasote, since the screws were not long enough to penetrate through the plywood. We then repeated the tests above with this homasote configuration.

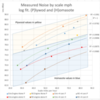

Finally, to satisfy my curiosity and because of several comments I've seen here, I removed the 1/2" #4 screws and installed 3/4" #4 screws in the EXACT SAME holes that resulted in the track being secured through the homasote and into the plywood.

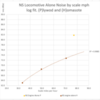

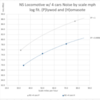

Photos of the experiment setup and relevant data below. We fitted a logarithmic curve through the three data points and plotted the R^2 values next to them. It's not a lot of data points, so the R^2 figures may not be as robust as we would like, but noise levels are measured on a log scale and these curves make perfect sense to us.

- The track was an oval of 14 piece, 133.25 inch nominal center rail circumference (nominal .1009 scale mi)

- "NS Engine" is my Williams Norfolk Southern 4270 "FA" Unit.

- "Erie" is my Lionel Postwar 2032 "A" Unit with solenoid E-reverser.

- The four cars used in the test were Lionel cars: Hormel boxcar GAH&Co 901, Reading Refrigerator car 16134, AT&SF Barrel car 356225, NYC caboose B&A 6920. The barrel car and caboose had pickup rollers installed and functional.

- The software used to measure the noise was "Decibel X Pro" for Android by Skypaw Software

- The plywood was 1/2" 5-ply "A/C" with the track screwed to the "A" side. The plywood was fastened to 1x4 benchwork using #8 drywall screws.

- The homasote was 4x4 ft, 1/2 in, sheet, attached diagonally to plywood with 1 5/8 in drywall screws, 8 around periphery, 2 in the center

- "Short screws" are #4x 1/2" wood screws to fasten track. "Long Screws" are #4 x 3/4" wood screws.

- Microphone was mounted and remained stationary for the entire test 35 inches above the center of the turn furthest from the wall. The raw data from the measurements clearly shows the train enter each curve with a slight change in SPL each time it straightens out. The data was overall very repeatable and very clean. Measurements Measurements are all Leq values in dB(a) at a sampling rate of 200 milliseconds. Most runs lasted about 30 seconds, some longer, some shorter.

Photos of setups:

It's not a truly scientific setup, but was certainly good enough for our purposes, and I wanted to share my results with you all. I've copied the relevant results to some images below, but the findings can be summarized as:

- PW loco was significantly louder than modern loco (no surprise)

- Speed is the single biggest factor in relative noise. Faster=louder (again, no surprise)

- Homasote generally results in a 6 to 8 dB(a) reduction in noise for identical track / train / speed configurations. (Expected some reduction, but this is significant)

- Track screws that penetrated the homasote and went into the plywood base did not appear to result in measurable noise increases versus screws that only penetrated partway through homasote (this was contrary to my expectations based on several comments in this forum).

In these charts, "P" = "Plywood Only" and "H" = "Homasote". Note that the "loudest" curve of any configuration on homasote was well below the "quietest" curve of any configuration on plywood. . There are a couple data sets we had to dump because there was an anomalous noise that affected the measurements (washer started on one, kids screaming, etc.). So some only have one or two instead of three data points, but it really didn't end up making a difference. So you can ignore the R^2 values where we have only one or two data points.

Here's all eight data sets together, with Homasote data sets highlighted:

Finally, here are data sets showing the long screws through to the plywood and the short screws in homasote only. No discernable difference:

Most importantly, these tests matched our own "ear tests". The homasote was a tremendous improvement in sound quality and loudness and general comfort being in the room with the equipment. In practice, 3dB(a) is about the limit of noise level difference that the human ear can discern, so 8 dB(a) is a really noticeable drop in noise and discomfort. So in conclusion, we're buying and installing the homasote, and would probably pay even more if it was more expensive than it is. The result is about $37.50 per dB of noise reduction, and Dad and I both agree it's WELL worth it!

Jeff