Hello everyone, just looking for some good ideas on how to cover the gaps between the homasote on my layout. I was thinking of putting packing tape over them but I'm not sure if that would effect securing ground cover due to the surface of the tape. I also figured using some sort of compound wouldn't work either as I will be doing work on top of the table from time to time. Any suggestions would be great and appreciated. Thank you!

Replies sorted oldest to newest

I tried my best to make my train tables as even as possible, and then used lichen or other scenery materials to hide any gaps between the tables. I tend to take the simplest and easiest Rube Goldberg approach to solve such problems. Arnold

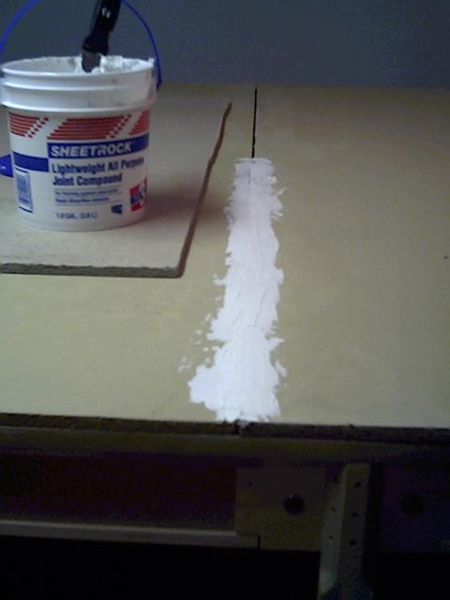

AJ - actually I would do both - wall compound to fill the crack and masking tape on top. If the wall compound splits the tape will cover it. When adding ground cover I assume you will be painting first so there will be no issue. Even if you don't paint and just spread scenic glue, ground cover will still stick to the tape.

A wood working treatment -but time consuming. Tape the bottom of the homasote. Make some (probably a lot!) saw dust. Pack it into the seams and add CA glue (thin liquid stuff). The mixture will be hard as a rock but can be sanded level.

Joe

Joe does the CA glue/saw dust solution effect the sound deadening capabilities of the homasote?

I did this a week or 3 ago. I extended some of my turntable whisker tracks in newly available square footage (workbench was moved) "land".

I filled the gap with plain old batroom/kitchen caulk, let it cure, then sprinkled/blended new dirt, then glued down with regular soap/glue/water mix.

The old land is at the loco pilots (I didn't even move them for the process, though I did drape a towel over them during the wet work). Longer locos will occupy these tracks. And that window is going.

Attachments

Using Joe's trick, you can first mix the sawdust with wood glue into a paste and then insert the paste into the gaps and let harden. It can then be sanded smooth. I then cover it with duct tape and haven't had an issue with the tape coming up. The tape comes in different colors and can be painted over, glued and ground cover applied over it.

Hi A.J. ,

The suggestions about using tape or glues as filler make sense, of course.

However, what I did was to ignore the seams, for the most part.

That is, I crafted all my vignettes and miscellaneous scenery onto baseplates, which provided a saving of time, effort, narratives, details, and expense when I have decided to change a scene by putting it elsewhere or altering it.

As I trust you can discern among these examples of my ignoring the seams on a layout, constructing each scene on its own base; then, filling in groundcover(s) and/or foliage, and neighboring vignettes, when desired and planned, obliterates any seams.

If a scenery/landscaping effort culminated in a seam still being visible, I have used tape or thick glues, like Liquid Nails or Gorilla Glue, to fill the gaps, which have been rare, and then I have crafted scenery elements over them, creating a seamless expanse...

I have other examples, if you would like to see more.

FrankM

Attachments

Moonson posted:Hi A.J. ,

The suggestions about using tape or glues as filler make sense, of course.

However, what I did was to ignore the seams, for the most part.

That is, I crafted all my vignettes and miscellaneous scenery onto baseplates, which provided a saving of time, effort, narratives, details, and expense when I have decided to change a scene by putting it elsewhere or altering it.

As I trust you can discern among these examples of my ignoring the seams on a layout, constructing each scene on its own base;

then, filling in groundcover(s) and/or foliage, and neighboring vignettes, when desired and planned, obliterates any seams.

If a scenery/landscaping effort culminated in a seam still being visible, I have used tape or thick glues, like Liquid Nails or Gorilla Glue, to fill the gaps, which have been rare, and then I have crafted scenery elements over them, creating a seamless expanse...

I have other examples, if you would like to see more.

FrankM

Frank, please correct me if I'm wrong, but are you essentially saying you filled in the gaps using a Rube Goldberg approach like I did, by covering the gaps with scenery materials?

If so, your Rube Goldberg approach turned out to be much more elegant than mine.

LOL, Arnold

Arnold D. Cribari posted:I tried my best to make my train tables as even as possible, and then used lichen or other scenery materials to hide any gaps between the tables. I tend to take the simplest and easiest Rube Goldberg approach to solve such problems. Arnold

Hey Arnold, you know good ol' Rube? He's my buddy too, he comes over and helps out quite frequently when I'm doing scenery work! ![]()

Small world, heh? ![]()

Richie C. posted:Using Joe's trick, you can first mix the sawdust with wood glue into a paste and then insert the paste into the gaps and let harden. It can then be sanded smooth. I then cover it with duct tape and haven't had an issue with the tape coming up. The tape comes in different colors and can be painted over, glued and ground cover applied over it.

Yes, this is probably a much better idea. Trying to sand a rock-hard CA glue seam level with a relatively soft substrate like homasote isn't going to end up quite as nice as you might at first believe.

Don't overlook light-weight spackling compound either, it makes a darned decent seam filler. Might even be able to mix with some homasote dust? Regardless, doesn't weigh much, dries fairly quickly, and sands quite easily. Good chance you won't even need to use any tape. ![]()

Whatever buildings and other scenery did not cover I just use duck tape over it and then paint it. My base is 2" foam and the rest you never see.

What Frank M posted is basically how I did it. Pay attention to what Frank has to say about scenery, he is truly the expert on this board.

Dave

This product comes to mind to use for filling in cracks here.

I use spackle, then paint over it. ![]()

Mitch

Paintable caulk. Done.

Moonson posted:... I have other examples, if you would like to see more.

FrankM

Yes, please; you do fantastic work. ![]()

Mark in Oregon

coach joe posted:Joe does the CA glue/saw dust solution effect the sound deadening capabilities of the homasote?

Honestly don't know

As the layout moves over time with contraction and expansion (yes, even in a climate controlled environment) anything like wood filler or spackle is just going to crack becoming visible again, even through your ground cover. Best to use something flexible when dried like a caulk, liquid nails etc etc and then cover the joint with masking or duct tape, then paint over it all with a thick layer of latex paint. Even if that joint does crack or separate over time, the tape will keep it concealed below the ground cover.

We used tape on some joints and not on others. The joints without tape eventually showed up on the surface through the ground cover. This is more likely to happen in states like CA where the ground is prone to shaking from the slightest of earth quakes. Most of you don't have to deal with that, but expansion and contraction yield the same result over time.

I filled the plywood panel butt joints with Elmer Interior Wood Filler using a putty knife, after the wood filler dried the joints were hand sanded with 150 grit sandpaper. I believe homosote is a paper based product, questionable if this wood filler would bond to homosote. Maybe a self leveling caulk might work, this is available at Menards, Home Depot , Lowes or your local hardware store.

Laidoffsick posted:As the layout moves over time with contraction and expansion (yes, even in a climate controlled environment) anything like wood filler or spackle is just going to crack becoming visible again, even through your ground cover. Best to use something flexible when dried like a caulk, liquid nails etc etc and then cover the joint with masking or duct tape, then paint over it all with a thick layer of latex paint. Even if that joint does crack or separate over time, the tape will keep it concealed below the ground cover.

I agree that a layout expands and contracts (it almost seems like a living, breathing organism) and flexibility is desirable when filling the gaps.

I used joint compound many years ago. Homasote will change dimensions. I opted to screw it down rather than glue it to the plywood. Years later I have some cracks. What shows is the white from the joint compound. Only the surface was painted then covered with ballast. If I were to do it over. I’d definitely leave a slight gap and then use a black silicon or caulk to fill the joint.

Strummer posted:Moonson posted:... I have other examples, if you would like to see more.

FrankM

Yes, please; you do fantastic work.

Mark in Oregon

Hi, Mark in Oregon, Thanks for being so laudatory and welcoming. So, here are a few more that may give a further perspective on what works for me regarding doing all my scenery on baseplates, which allows me to ignore any seams where plywood sheets abut..

I am letting you see the edges of the acrylic

and Masonite bases upon which every scene...

is crafted.

The Masonite gets screwed down, however, to guard against any possible warping from any possible future moisture in the trainroom. As an example of that, an edge of the Masonite sheet utilized under this trailer encampment, with one of its screws, is visible to the left of the wooden fencing........

...and in this particular scene, you can discern a seam between the two vignettes (just to the right of the man wearing bib-overalls, attending to the horse) before being obliterated by further groundcovers and foliage, which blended the two scenic elements into one vista...

before being obliterated by further groundcovers and foliage, which blended the two scenic elements into one vista...

FrankM

Attachments

Fantastic! (did I already say that?) ![]() Everything looks so "natural".

Everything looks so "natural".

Your trees are great, and I love the way the gazebo is tucked into those trees in the 2nd picture; not to mention the little farm scene. ![]()

Yours is such a smart approach, especially given your high level of detail: you detail the heck out of a given scene, and then integrate that into your layout, as opposed to taking on the seemingly monumental task of detailing the whole thing in one "piece". Very clever and worth noting.

Thanks for posting these...and for the inspiration.

Mark in Oregon

Frank, IMO your approach using vignettes and to scenery in general is ingenious.

Where my cork roadbed doesn't cover the gaps between my sections of plywood I use blue masking tape then cover with plaster and then ground foam.....................Paul 2

What I did was take some old white cotton bed sheets, tear them into 3 inch wide strips. Mix up white glue and water. Brush on the glue mix over the joint. Carefully apply the cotton strip over the gap, feather out the edges, then apply more glue mix. Let it dry, then paint the table top a light brown earth color. The joints are hard to see. As you add more ground cover they will be totally gone.

Steve

Hi Monsoon:

I like your baseplate approach.

You stated that Masonite & acrylic as the materials for your baseplates.

What are the pros & cons of using Masonite Baseplates ? What thickness do you use ?

What are the pros & cons of acrylic baseplates ? What thickness do you use ?

Thanks in advance !!!

@John Ochab posted:I filled the plywood panel butt joints with Elmer Interior Wood Filler using a putty knife, after the wood filler dried the joints were hand sanded with 150 grit sandpaper. I believe homosote is a paper based product, questionable if this wood filler would bond to homosote. Maybe a self leveling caulk might work, this is available at Menards, Home Depot , Lowes or your local hardware store.

Isn't paper a wood based product?

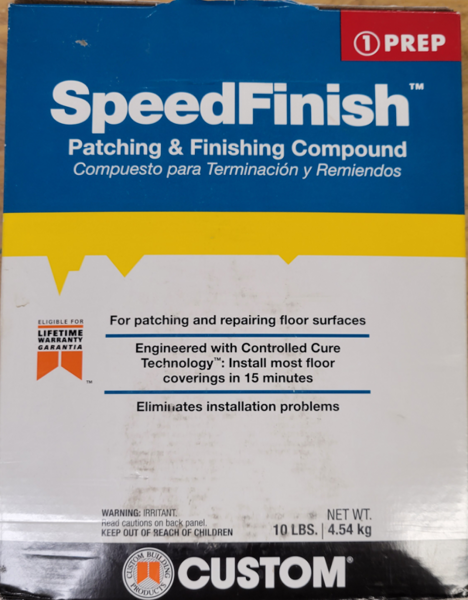

Actually, the method that @Tom Tee mentioned several years ago in this thread works really well and is quick and fast, not to mention yields a near perfectly smooth result!

Here's my yard after filling the Homasote screw holes and seams with Speed Finish filler.

After a coat of brown paint as a base and to keep dust down.

Attachments

@A.J. posted:Hello everyone, just looking for some good ideas on how to cover the gaps between the homasote on my layout. I was thinking of putting packing tape over them but I'm not sure if that would effect securing ground cover due to the surface of the tape. I also figured using some sort of compound wouldn't work either as I will be doing work on top of the table from time to time. Any suggestions would be great and appreciated. Thank you!

Here's how I filled in the gaps between Homasote sheets on my last layout which I built in 2007. The gaps were still filled when I took the layout down in 2019 when we moved to our "forever home".

After filling the crack and letting it dry for a few days, I sanded it down so I had a smooth surface, then painted it to match the brown paint I used earlier on the Homasote sheets. Here's how the same place looked during the "first run" after I installed track, roadbed and wiring. The crack I filled, sanded and painted runs across the layout from the left side by the mainline cross-over turn-out near the locomotive, through the stub tracks and on to the other side of the layout.

In this "second run" photo, the crack I filled, sanded and painted is invisible--and stayed that way for the life of the layout.

BTW -- When I purchased my Homasote, the small lumber yard's manager kidded me, "Whatcha building, a music studio or a train layout?" He also told me to paint all six sides of the Homasote (top, bottom & side edges) to seal it against moisture absorption before gluing it to the plywood with Liquid Nails.

I hope this info is helpful!

Attachments

@gunrunnerjohn posted:Actually, the method that @Tom Tee mentioned several years ago in this thread works really well and is quick and fast, not to mention yields a near perfectly smooth result!

Here's my yard after filling the Homasote screw holes and seams with Speed Finish filler.

After a coat of brown paint as a base and to keep dust down.

Thanks for the product info John. I've been looking for somthing also. You and your friend Tom always show nice clean work so I will pick some up.

Here's the exact product I used, Tom actually brought this up when we did the main layout platform. It went on easy and sanded smooth very quickly.