POST 15:

OPERATING TMCC ENGINES VIA MTH DCS REMOTE.

(Note: I don't claim to be an expert on this subject so please feel free to add corrections and/or other resolutions).

One can operate both TMCC and DCS using their respective remotes but I decided to have everything under the DCS remote. I don't know about the new legacy TMCC but I've got the very first TMCC cab 1 and I find the controls on the DCS are more intuitive to use than the controls on the TMCC (your comfort maybe the opposite).

A nice option I like on the DCS remote is being able to startup and shutdown an engine on the track. For some reason it bothers me having the circuit board 'on' when the engine is not in use for long periods of time. With the DCS remote this is easy to do. Unless, I'm missing something, with TMCC, I have to key in TR 1 and rotate the throttle down to turn off all engines....and then start up again to get another engine started after just running a different engine.

My new DCS system just came in today. The very old one's circuit board fried (no fuses on the original). It was so old that it had a VCR tape for instructions!

I've got three engines that are TMCC and set them all up under TMCC using the last two digits of the engine number (required before setting up under DCS).

I've got 4 track loops (trk 1,2,3,4).

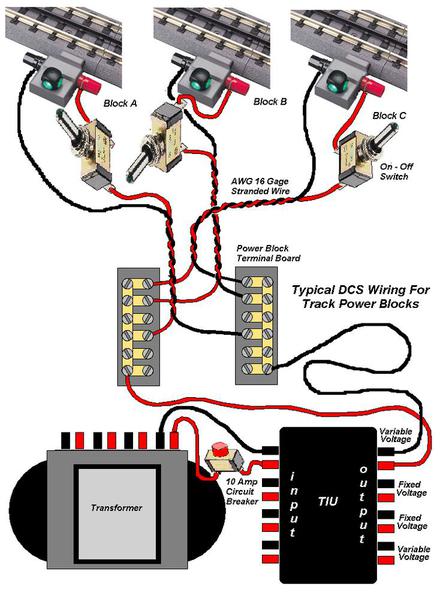

TIU

Input side:

Var in 2:

has a ZW-C with a brick.

Fixed in 1 and 2:

The MTH Z-4000 two outputs connect to these.

Var in 1:

a 180W brick.

Note: For power input, 4 bricks could be used instead of a ZW-C/L or z-4000. Best not to use old transformers as the circuit breakers are slow: not good unless you want to fry $200 engine boards! At the slightest wheel off and short, the circuit breakers trip on my bricks: a hassle to go back to reset them BUT cheaper than new boards! Best to keep the bricks within easy reach on a layout.

Output side:

Var out 1:

nothing connected

Fixed out 1:

Trk 1 & 3

Fixed out 2:

Trk 2

Var out 2:

trk 4.

NOTE: updated.

When running the 14 car passenger train, the passenger lights would oscillating dim and get bright and after awhile, the Z-4000 red light came on.

I'm guessing that due to the large number of passenger cars on all the tracks (32 cars), they were over drawing amps on the Z-4000 and causing the short (red) light to come on.

Initially, I was not using var 1 output so I connected trk 1 to var 1 output to get more power (as Tim would say!). Since Var 1 output is, like variable, I first have to select TR button and sel Var 1 and throttle up the volts to 18 (only gave it 18 versus the max of 22). I also connected the TMCC base wire to all output grounds. This seems to be working much better.

Output side now looks like:

Var out 1:

Trk 1

Fixed out 1:

Trk 3

Fixed out 2:

Trk 2

Var out 2:

trk 4.

Trk 1: runs TMCC engines (4)

Trk 2: runs just the SF PA set

Trk 3: runs MTH engines (5)

Trk 4: runs an old proto GN F-3 set (var 2 selection)

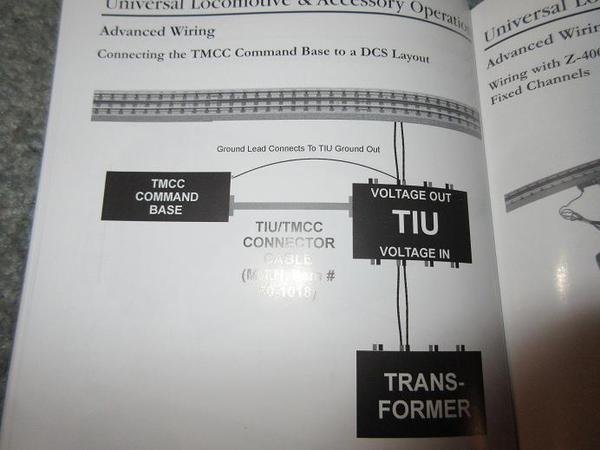

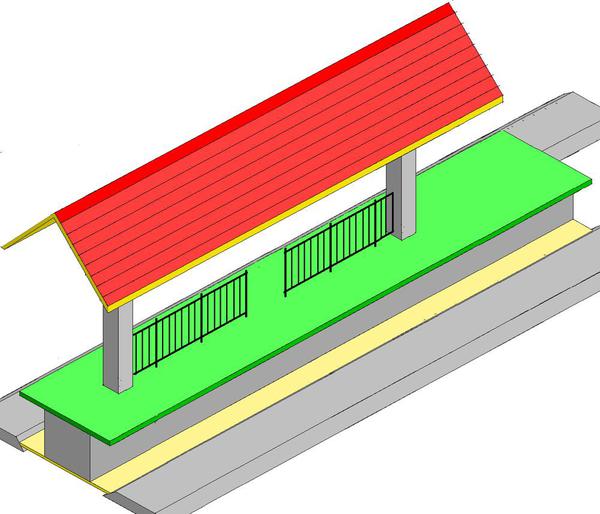

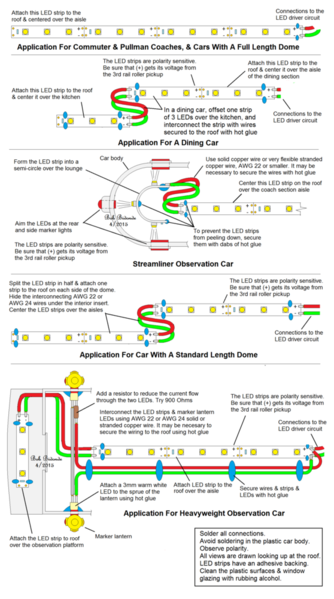

Messy so see MTH's pictoral:

ps: the flat face V transformer runs a 5th track which is conventional.

MTH DCS: hookup.

The pictorial (much neater!)

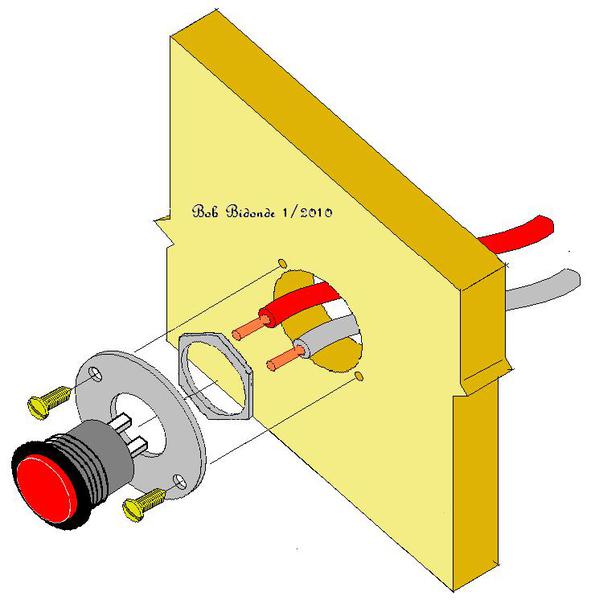

Need 50-1032 TIU/TMCC connector cable (each end is labeled)

Note: TMCC command base connected to output ground side.