Hello Gents,

I have a Premier PS2 Hudson steam locomotive using DCS. The smoke worked fine, but recently the smoke was ON in DCS but it may have run out of smoke fluid.

I added 15 drops, tried it, no smoke. Then added 10-15 drops, no smoke. I do hear the unit turn on if I turn engine sound off and if I plug the exhaust momentarily with my finger, I see a bit of smoke for a second.

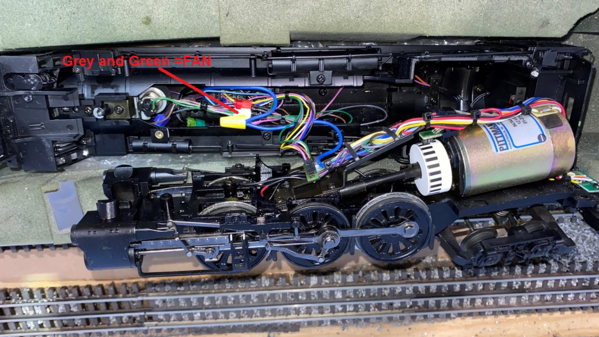

How should I troubleshoot? Note that I started to try to remove the shell to look at the smoke unit, but I'm not locating all the mounting screws. There are two in the back that are obvious. The rest I'm not sure of. The manual for the engine doesn't help.