A little train nut humor . Everyone go to Big boys house and hold our hands over the engines as they run.... Fixed. (ok Fail )

It would give new meaning to the term "operating crew".

Let's address this morning's comments and ideas.

Nick, the systematic re-powering of the layout sections was actually next on my list. What happens when the base sees more layout and more trains? The extension cord test may not be possible due to the lack of cords of sufficient length. I'm not sure that would prove anything new, since I have now established some level of signal on the layout using the conduit based system. Losing that system is not really an option.

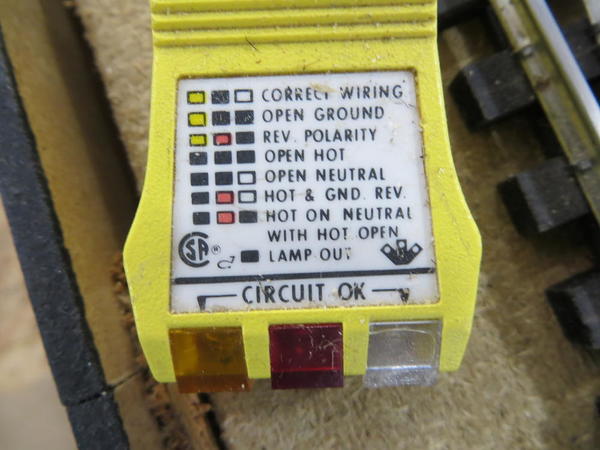

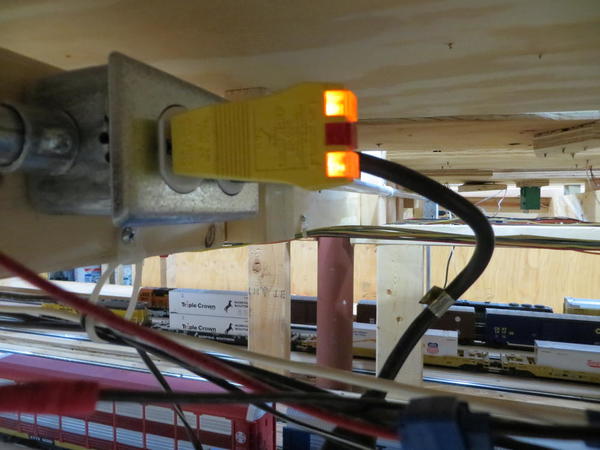

JGL, These photos actually prove that that is not an issue. The ground is good, and the conduit system is working correctly. If it wasn't, only one light would come on.

That is not the case.

There is also the matter of all my ground planes being tied to the conduit in one way or another. They are all working. Also, thank you for pointing Big Dodge in the right direction.

That said, it is probably best to just give the layout's vital statistics here, as they could be important to this discussion.

- The room is 1900 square feet

- The layout with all 3 levels is about 2200 square feet (yes it's bigger than the room)

- There are over 3000 feet of track

- There are just over 300 switches

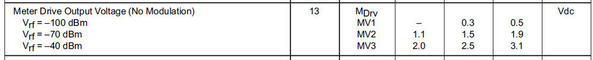

Chuck, I would have thought that too, but the evidence doesn't seem to support that theory. I'm guessing that the decks are too far apart for the chicken wire below the upper to help signal on the lower. Dale's meter should be in today's mail, but it hasn't come yet. Mail comes shortly. I'll let you know the results.

John, I agree. I just want to exhaust these other possibilities before embarking on that amplifier. I do believe that is where we will end up. And pray that that ends it.

Dave, at this point, Dale is invited, but no plans to visit have been made. I just bought his signal strength meter. That's why this forum is so great. We can have this discussion, and even though it is specifically about my layout, the information shared may be useful to others and open to all.

One final thought, and this would be a little embarrassing if were true. The wire I used to connect the layout to the bases has a ring lug crimped onto it. I did this because the spade lug I was using, kept coming loose from the post on the TMCC base. When I went to connect it to the Legacy base, I had to drill out the ring to accept the larger post. However, the design of the Legacy post expects you to insert the wire into a hole through it. What if the ring didn't make contact with the post?

In my most recent successful tests, I clipped a test lead to the ring and the post, and things worked. <shrugs shoulders>