**Update** Because I have selected a layout for my first build, I figured I would change the focus of this thread to show my build progress. Since I'm finding this forum so helpful, I want to continue this thread so I have a place to ask questions and possibly give other new hobbyists like myself tips and ideas for their first build. If this is not the correct place for this topic, please let me know and I will start a new thread elsewhere. -Brad

Hi All. My first post.

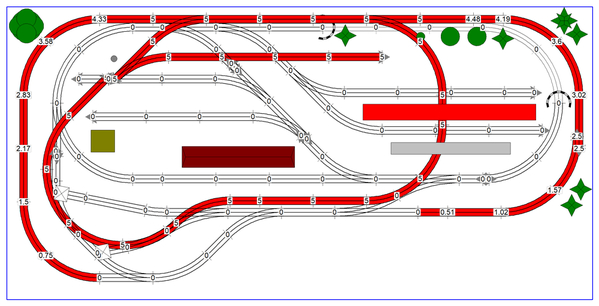

I'm brand new to the hobby and this is my attempt at a 4x8 layout. I only have a small room to work with so 4x8 is my limit for now. I may have tried to cram too much onto one sheet of plywood but I wanted to get your opinions.

I plan to have a couple small "mountains" and tunnels for the lower track at each end of the elevated track. I'd also like to have a couple bridges on the two straight sections. I will probably not have any industry accessories but I will have a few small buildings. I'm aiming for late 19th century to early 20th century rustic. I don't know a lot about this time period but I'm learning.

I purchased an MTH RTR starter set last month. I added a couple of switches to get a feel for how this works. I will be using MTH RealTrax for this layout and I have purchased an MTH Z-1000 Power Supply.

I'd love to hear your ideas, comments and concerns about my plan.

Thanks, Brad