You have to have a common for the led to light. When the switch is off there is a connection between acc and ground.

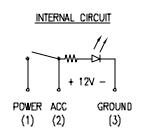

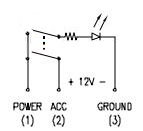

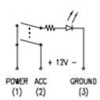

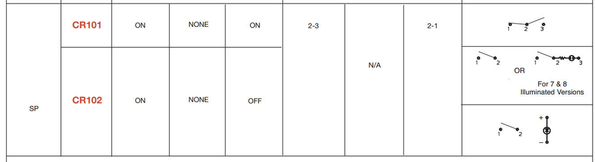

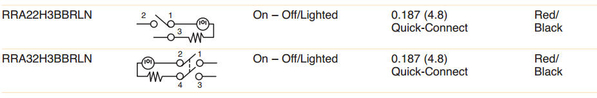

I thought my switches were constructed that way, that the wiper is on power for on and connected to earth for off shorting out the diode and connecting the load to earth. But mine are not. Here is the schematic for my switches...

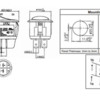

My switches are Calterm 40393 12 vdc automotive switches. I bought them from the Farm and Fleet store here in IL.

They say SPST so I should have questioned the shorting or not shorting issue before. I took one apart and it clearly does not short the load to the earth terminal, but it looks like it could have if a little tab was a bit longer. Maybe other brands or versions do, but the #40393 does not. So good on all accounts, mounts in a round hole, good for 10 amps or more, doesn't short out the siding when off, LED illuminated at the RMS voltage of 12 volts when powered with 18 VAC, and somewhat cheap at $4.22 at the Home Depot and elsewhere (just looked it up...).

EDIT: Still good but the schematic is now a DPST as pointed out by Stan2004 since the LED does not light up when applying power to ACC (LOAD) and Earth. The one thing I did not check when I measured with an ohmmeter. Also when I shorted across the turned off block and the live loop track, the block lit up with power and the LED stayed off on the switch. Might have been informative if it lit up...but didn't as Stan pointed out.

https://www.homedepot.com/p/Ca...itch-40393/303616206