I ran across this place in my travels, and I figured I'd share the news. ![]() This is the cheapest place I've found that offers small quantity runs of quality printed circuit boards.

This is the cheapest place I've found that offers small quantity runs of quality printed circuit boards.

An interesting outfit, looks like a real handy place to know about. To give a test of the service, I fired off a couple of small orders, and true to the ads, the total price was really what they said! Free shipping in the US? How is that possible at those prices?

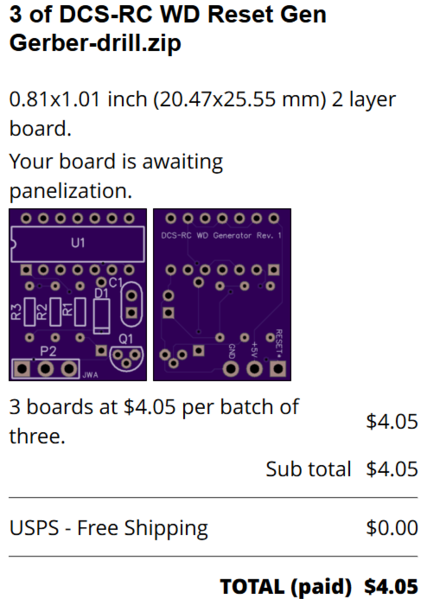

I did two boards to try different options, some of the recently finished DCS-RC Reset board, and a few of the LMS boards. I went with the thinner boards for the LMS to see what that got me. Note that you get a square inch for $5, and you get three boards, so it's really 1/3 of that. With free shipping, it's hard to imagine doing this much cheaper! You can order more in multiples of three, so I did six of the LMS.

The offer all sorts of stuff that you don't normally find with a cheap prototype board, slots, custom outlines, etc. Usually, you're much more limited in the design.

Their model is they take a lot of these small orders and combine them into large panels and manufacture it, then cut it apart for the individual shipments. I suspect they actually do three or four panels with a single copy of each design so they don't lose them if they have a process issue for one board.

I predict this may become my new favorite prototype board house. ![]()