I wanted to share with you these photos of a VL BB #4004. I wanted to see why I paid $2000 for a toy train. I also wanted to check to make sure all is well inside the boiler. Of course I was also curious as to its design compared to my MTH Premier BB also cab #4004.

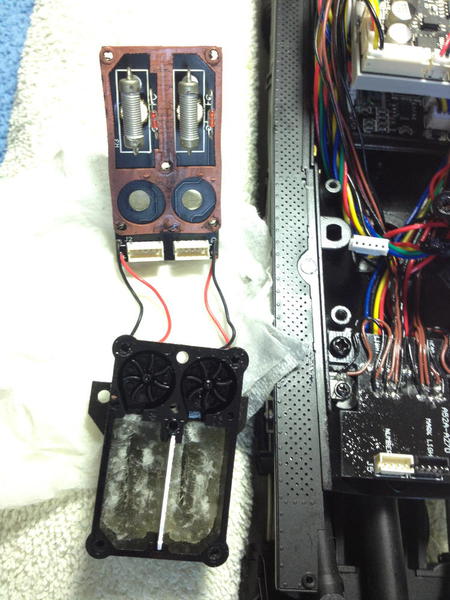

There are four smoke units in the VL BB and I went through them and did some adjustment to the heat resistor and the heat sensor that one can see right next to the heat element. Therre are some any thoughts that came to mind but I shall let you look at the pictures and you may ask any questions and I'll do my best to answer them. I enjoy the knowledge and the help on this site and I'd like to be able to add some help to if at all possible. I am not an expert, just having fun!

.....Thanks for looking

Stock picture from Lionel site, below it is the actual model.

The blow down hose was almost off!

Main stack units and whistle unit. They have to be precision mounted to the chassis for the top boiler to fit well. The black plastic output have to fit inside the top boiler, there are three stack, not easy to accomplish. Lionel did a great job here

Wires, circuit boards, switches, and the great speaker enclosure. Lionel uses clear, thick and soft plastic to house the dual speakers. I think this material enhances the sound quality, better than MTH black thin and stiff plastic...just my observation!

The main stack units, note the sensors. I tried to center the heat element in the reservoir. I also moved the sensors about 2 mm away from the heat element thinking it may improve the smoke quality, I think it did but I have no qualitative data to support such claim ![]() . Note the saturated material with smoke fluid. Lionel did not mark which is the front or rear stack connector, they ar both white but their harnesses are white and black, I took a 50/50 guess

. Note the saturated material with smoke fluid. Lionel did not mark which is the front or rear stack connector, they ar both white but their harnesses are white and black, I took a 50/50 guess ![]()

The blow down unit. Many wires flying everywhere, must be extra careful.

A closer look. The blow down unit is all over the flywheel and drive u joint

I added a tie wrap on the blow down hose.

This is the tube the directs the smoke to the blow down ports. Note the Pittman motor, made in the USA? great! Brass elbow to prevent hose collapse.

The sensor to turn off the front smoke unit when the "hood" is placed, great thinking on Lionel's part to prevent heating up the front smoke unit.. Note the three wires routed around the smoke opening, again, utmost caution is needed they do not get pinched by the black plastic exhaust stacks when the top boiler is replaced. Also note the wires for the headboard lights and marker lights...same caution is needed. Many of the wires clips were loose, A drop od thick CA took care of it. I also added a drop of CA glue to the three wires to keep them in place (red, black and white)

The top boiler assembly. very well done and crisp die casting but in my opinion can use more details for such a high end VL unit.

There is a divider between the front reservoirs. I thought of removing the aluminum divider to increase capacity BUT, that may ruin the synch chuffing effect, a feature I really really like at very low speeds!

The divider removes easily.

Many wires very near the flywheel, danger zone. The flywheel was wobbling a lot during operation, I did not like it, I may contact Lionel to see if there might be a latent problem with vibration!

Note the drive shaft! many wired very very close to it, I re routed some and tie wrapped some to reduce such risk. The two big screws that hold the switch assembly were loose.

Switch board and more wires

Over all, I am happy with the Engineering that Lionel did on this model, it is not just a toy train in my mind. These are hard to deign, build, assemble AND assure some quality control. Many potential problems exist due to complexity so supervision is mandatory at the factory in China!

Taking off the top boiler was a piece of cake, four screws, putting them back on took me more than an hour because I wanted to make sure no pinched wires would cause a disaster and I hate returning locos ![]()

Lubed and greased the gearboxes (BTW, one gear box had brass gears the other engine has steel gears???, ran the loco without the top boiler first and adjusted smoke units and I then ran it with the boiler on but NOT screwed, then finally I added the four boiler screws and re tested it...I was lucky I did not blow it up, it ran well and smoked like a chimney. I am using MTH smoke fluid, Xmas scent no less ![]() All the smoke units seem to smoke better now!!!

All the smoke units seem to smoke better now!!!

Live long and prosper!