Open L-Girder frame completed and now considering insulation foam board on top. I have built several layouts using plywood or MDF before and both have merit, but I have never worked with foam board.

Layout is 72"L x 64"W - odd shaped which would require cutting the foam board to length and joining sections for the width.

1) Does foam board cut "clean" and can cut sections be joined using methods besides tape? Assuming glues do not stick to foam.

2) Some boards have foil backing on one side, I assume this cannot be removed and should be placed facing down. Any affect on wireless signals?

3) What is best method for attaching the foam to wooden layout frame work? Cross pieces are 12" apart, 3/4" thick painted poplar wood.

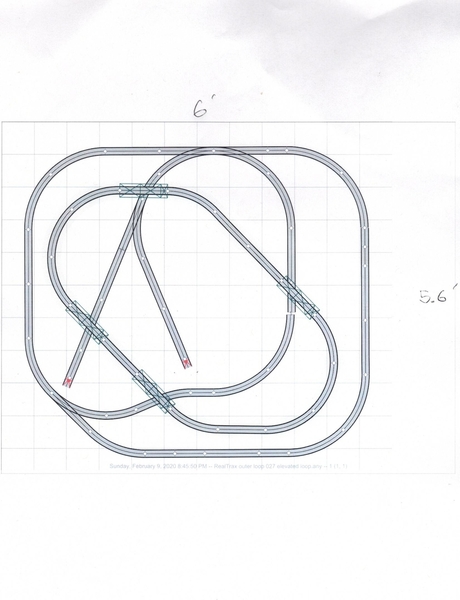

4) How well would track screws hold in the foam, Using MTH RealTrax initially, but this is a test bed for different track plans, including tracks without roadbed.

5) I am planning an elevated loop, can wood supports be attached to foam and how well would joint hold up to 10 pounds of O Gauge trains?

Thank you! Alan