Read through most of the 5 pages of responses. Thought I'd add a couple of my own experiences, throughts...

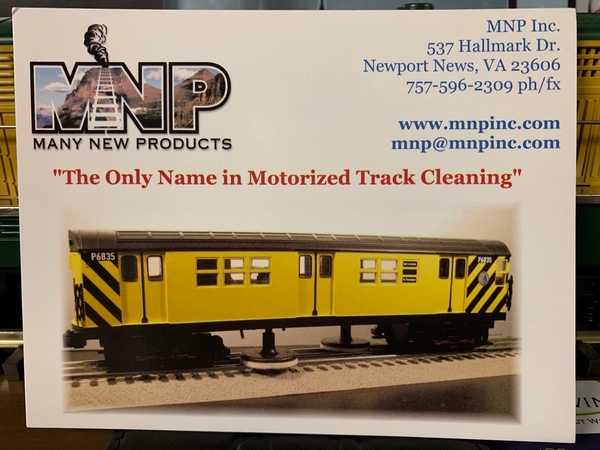

I have used Centerline cleaning cars in all the gauges. Usually with Goo-Gone. Follow-up with dry rollers for any excess. Works well. Have used on O, HO, N, and G layouts...some are mine, others at the LHS, and still others for maintenance clients.

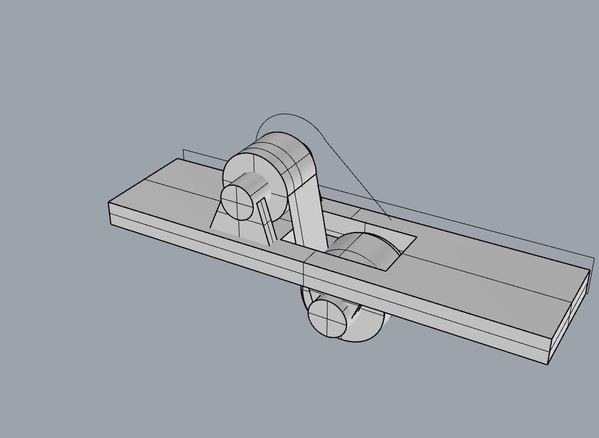

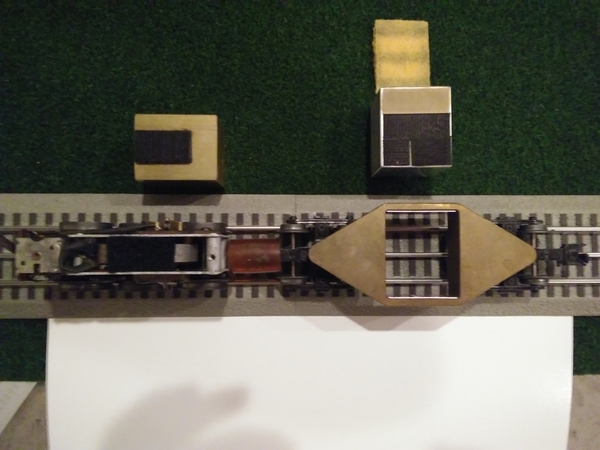

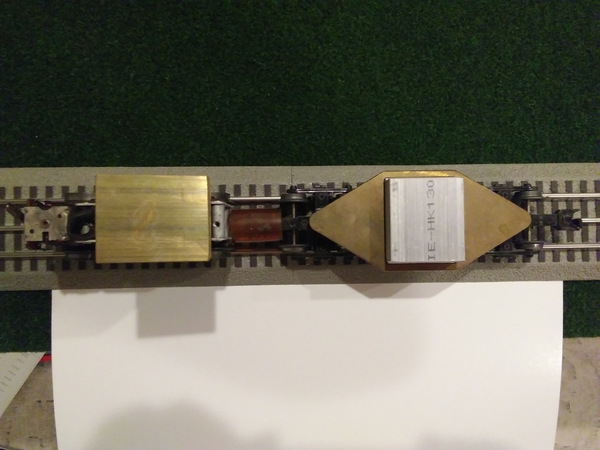

For the G layouts (indoors, clients) I've also modified a 'Bright Bar' rubberized abrasive bar sold by Micro-Mark to ride in the Centerline pocket for the client's brass track. I bevel the edges (to ride the rails better) and trim the block to fit the car pocket. I set a steel weight on top of the block when it's being pulled through the layout to ensure a good brightening of the brass track. I also have/use the LGB motorized track cleaner, but the client is often busy with his own clients and it makes a lot more noise traversing the layout (runs overhead through his office, hallways, lobby, etc.) than the Centerline pulled with a Stainz (0-4-0).

For my O3R layout I use the Northeast car that others have discussed in the responses. Actually, my own car looks very much like LeapinLarry's with the tank and engine details. Excellent job. Goo-Gone. Dry wipes to finish.

--------------

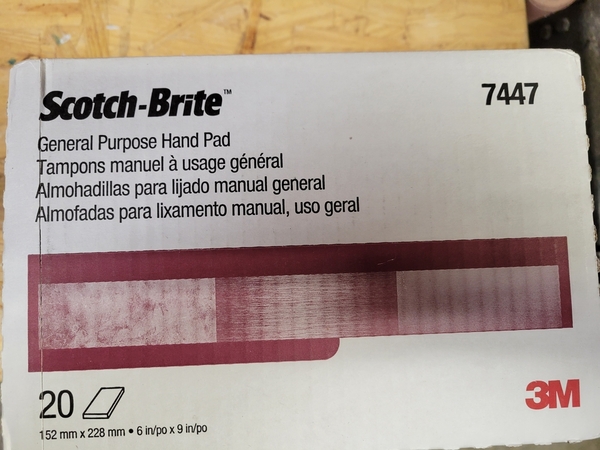

A thought about the Scotch-Brite pads... I hadn't really needed something that aggressive for track cleaning. Also, I know they (green ones) are prone to scratching plastics and even 'fogging' a high glossed paint finish. They have their place in the tools inventory, however.

But a road trip to Florida in May a couple of years ago introduced me to a better version of Scotch-Brite pads. What I didn't know on that trip was that I was driving right into the peak of MAYFLY season! For those not acquainted, these are the horny buggers that hatch in May, fly around densely and desperately to find a mate and, well, you know!.... . Females live for 5 minutes, males two days...MAX!(and we thought Covid was a PITA!!!) Well, when they get plastered all over the front of your car, then bake a few hours...or more... in Florida's sun, you're headed for a MAJOR car washing experience unknown 1300 miles in the other direction.

. Females live for 5 minutes, males two days...MAX!(and we thought Covid was a PITA!!!) Well, when they get plastered all over the front of your car, then bake a few hours...or more... in Florida's sun, you're headed for a MAJOR car washing experience unknown 1300 miles in the other direction.

I was warned that commercial bug-booger softener liquids/sprays will help, but that new-car gloss/shine will need more. That's when I became acquainted with Scotch-Brite's PINK scrub sponges. These are so mild they're "Safe on stemware, china, mirrors, and more!". And on car finishes, too, I found out. TOTALLY AWESOME. Noooooo bug-booger residue, minimal effort required.

And, so, naturally I had to try them out on some of my railroad equipment in need of cleaning. EXCELLENT! Now, also part of the tools inventory. So, for those who are concerned about the aggressive nature of the more common green Scotch-Brites, I highly recommend the PINK versions.

----------

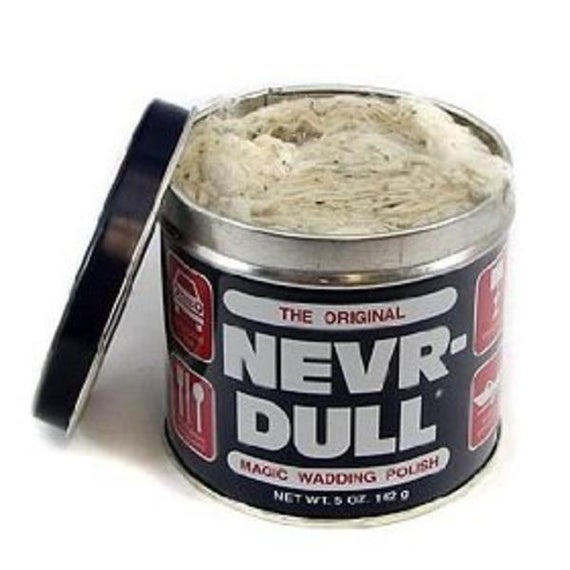

Lastly, re Deluxe Materials Magic Track Cleaner... It is, indeed, an excellent product. And a late-comer to the market. Our LHS stocks it, customers who've tried it are pleased. So, why hasn't it been more to the fore? Well, Deluxe Materials is a UK company. If you peruse their UK website, you'll find they make LOTS of products for the hobbyists of all branches...including the railroaders. But it's only within the past couple of years that they've linked up with state-side distributors to make it easier to obtain.

In fact, if you go to the Magic Track Cleaner link...you'll find a note at the bottom that sez they can only mail within the UK, not overseas. Well, that applies to direct orders. You can obtain the product from a state-side distributor, which are identified in the website.

Take some time to investigate their other products...

FWIW...

![20230424_024204[1] 20230424_024204[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/132630114287720721/filePointer/173456840830708566/fodoid/173456840830708558/imageType/MEDIUM/inlineImage/true/20230424_024204%255B1%255D.jpg)

![20230424_024204[1] 20230424_024204[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/132630114287720721/filePointer/173456840830708566/fodoid/173456840830708558/imageType/SQUARE_THUMBNAIL/inlineImage/true/20230424_024204%5B1%5D.jpg)

![20230424_164735[1] 20230424_164735[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/132630114287720721/filePointer/173315960891390005/fodoid/173315960891390001/imageType/MEDIUM/inlineImage/true/20230424_164735%255B1%255D.jpg)

![20230424_164735[1] 20230424_164735[1]](https://ogrforum.ogaugerr.com/fileSendAction/fcType/0/fcOid/132630114287720721/filePointer/173315960891390005/fodoid/173315960891390001/imageType/SQUARE_THUMBNAIL/inlineImage/true/20230424_164735%5B1%5D.jpg)