I’m adding a point to point trolley to my lay out. I’d like it to automatically stop for 30 seconds or so for unloading and loading at each end of the run. Is their some kind of control or wiring trick with which I can accomplish this?

Replies sorted oldest to newest

Sure.

Here are a few potential options to start with, particularly if you don't mind using electronics to accomplish the task:

1.) DZ-1240 Auto Stop & Reverse Module by Z-Stuff for Trains

2.) Blinking Auto-Reverse Controller by trainelectronics.com

3.) AC Auto Reverse Unit, Model ARUE by Pocono Mountain Lines

The ARUE is quite old, and I believe they may be out of production, but can occasionally be found at train shows.

4.) For something more sophisticated, and particularly if your haven't purchased the trolley yet, you also have the option of using one of several made by MTH, and streetcars as well, which have this kind of functionality, along with station stop announcements, built-in to them (and programmable).

5.) Also on the more sophisticated side check out this thread if you're looking to use loops at the ends of your trolley line:

https://ogrforum.ogaugerr.com/...72#80551019692618872

It refers to using SuperStreets vehicles (taxis) instead of trolleys, but they work in the same way.

6.) Finally, if you'd prefer non-electronic instead there's always the classic bump-n-go trolleys that reverse using electromechanical means by running into bumping posts at each end of the line. No auto-stop for 30 seconds here though.

Many choices.

Mike

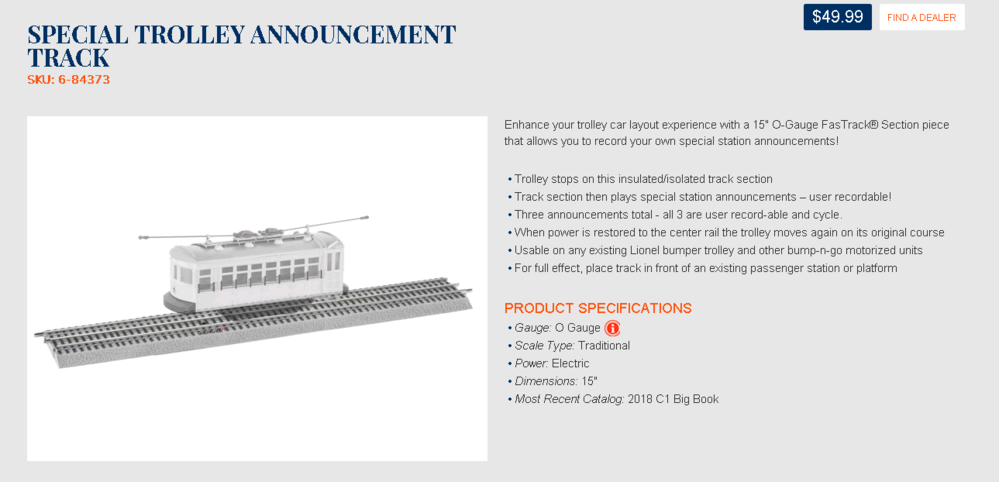

By far the easiest solution is Lionel's Special Trolley Announcement Track: http://www.lionel.com/products...ement-track-6-84373/

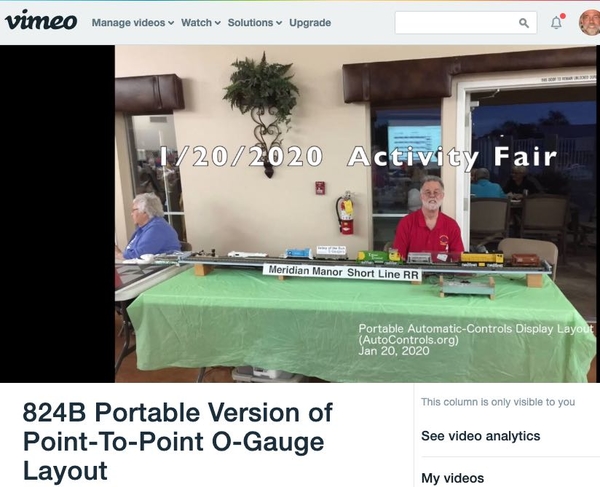

Attachments

Bachmann has offered a point-to-point trolley set in On30 for several years. The most popular of these sets is in a Christmas motif, complementing the wide range of ceramic villages available from different mfrs. But, Bachmann has done this set in a more common, non-seasonal set decoration. And those trolleys are available separately, too.

If you want intermediate stops on this sort of a set-up, I highly recommend Dallee's trolley stop-and-go system using current-sensing for detection. For all the years we used this system (Our Christmas metropolis became overwhelming to recent demise as the body became less flexible!![]() ), it worked flawlessly.

), it worked flawlessly.

FWIW....

KD

Link to a complex Dallee trolley control system Back and Forth, there is a timed middle stop. There is a minimum track length necessary for all the sensor sections. Not for bump and go trolleys. Trolley with Forward, Neutral, Reverse electronic control. Click on underlined phrase to link.

Do you already have the trolley car(s) you want to use in-hand?

As suggested by others, there are several off-the-shelf "systems" that can intermittently stop, reverse, delay, etc.

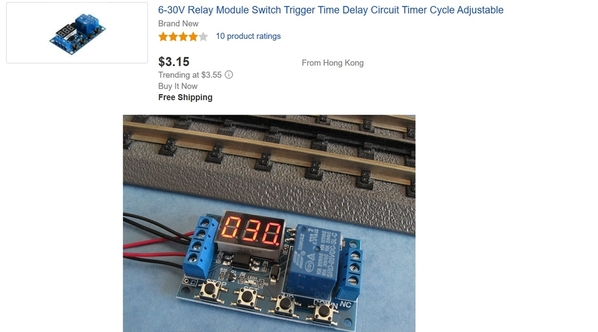

Most guys on OGR want an off-the-shelf, plug-and-play solution. But if you don't mind DIY wiring, you could cobble together some timed-relay modules (a few bucks each on eBay) and get it done for, say, $10 out-of-pocket. If this applies to you, I can elaborate.

AC trolley vs DC , bump&go or, 2pos. or 3pos. E unit... Each trolley type may need /use a unique method. But it can be done.

I run my subway on DC and use modules like these (Fleabay LED-Delay-Time-Module-Switch-Board-Control-Relay-Cycle-Timer-DC-12V-Button/352972310512) for timed stops.

Another vote for the Dallee system.

The trolley comes into the station and stops. The lights go off and the direction reverses. The trolley

on the next siding turns the lights on, waits 10 seconds for passengers to load and slowly takes off. The

other end of the line is a reverse loop so the trolley returns and the process is repeated with the

trolley on the other siding.

The trolleys are controlled via TMCC which is initiated by insulated rails on each siding. An Arduino

then sends TMCC commands to the TMCC base.

Attachments

1. Simple DC Polarity Reversers:

If you can operate the trolley on DC, and do NOT require an intermediate stop -- then there are a BUNCH of systems that use a gapped section with a diode at each end of the track, and a controller that simply reverses the track polarity using a timer.

- These are probably the SIMPLEST way to do automatic shuttle operation.

- When something is not working right, they are relatively easy to troubleshoot, because the track power is ALWAYS on, it just peridically changes polarity.

How They Work:

- When the trolley reaches the end of the track and crosses the diode section, the DC current cannot propel it any further in the direction it was going.

- It sits and "waits" until the polarity is reversed, then the diode allows current going the other way to reach the motor, and the trolley starts up in the other direction.

I attempted to do a DEMONSTRATION of this type of unit in this video: https://youtu.be/VEHfVsTxZL0 .

The below IMAGE shows the LGB loco and the S gauge loco I used, but the gauge doesn't matter -- as long as the loco runs on DC.

I think the Bachman system that 'dkdkrd' mentioned above, uses this type of system.

These controllers are fairly simple for electronics people to build, and I think you can get the more "homegrown" versions as low as around $30.

The units usually include a knob that controls the time delay between polarity changes, which controls how long the trolley sits at the end before it starts up in the opposite direction.

- In the above image, the blue box is the controller

- The black knob on the top of that blue box, controls the time delay.

- This unit is a no-longer-made PH Hobbies unit, but currently-made units operate pretty much the same way.

- Dallee Electronics makes a basic "back and forth" unit, details on this page: https://www.dallee.com/Back-N-Forth-DC-1-amp-561 .

- They appear to be priced at $45 for 1 amp unit, or $50 for 5 amp unit.

Warrior Run Loco Works located in NE PA, was marketing a "home grown" unit a couple of years ago for around $30. I can't find it on their web site, but they may still produce it.

You can sometimes find these USED reversing controllers at train shows.

- LGB has been making these units for years.

- Also Split Jaw made them; they're now out of business, but many used ones seem to be around.

2. More Sophisticated:

If you want a more sophisticated unit, Railroad Concepts makes a "Stationmaster Reverser" unit that does gradual acceleration/deceleration, plus intermediate stops. Details here: http://rrconcepts.com/Reverser.shtml .

3. DCC Option:

If you didn't mind using standard NMRA DCC, you could use an NCE DCC "Mini-Panel" Programmable Train Controller to run a unit point-to-point -- with the added BENEFIT that you can have lights and sound ON -- all the while that the trolley is stopped. (You might have to "lean" on your HO friends, who are probably more familiar with the DCC stuff.)

I did a 2-minute-long video demo of this type of operation using two MTH Proto 3 locos in this video: https://youtu.be/y9NASFyoJ5o .

Just pretend those two MTH locos you see in the below IMAGE are trolleys, and hopefully it gives you the idea.

Attachments

Great summary James! ![]()

I was hoping the OP would let us know what kind of trolley he has or is considering. It's such a difference if command-control is in play, or if trolley uses a traditional AC E-unit if lights/sounds at the timed stops is of interest.

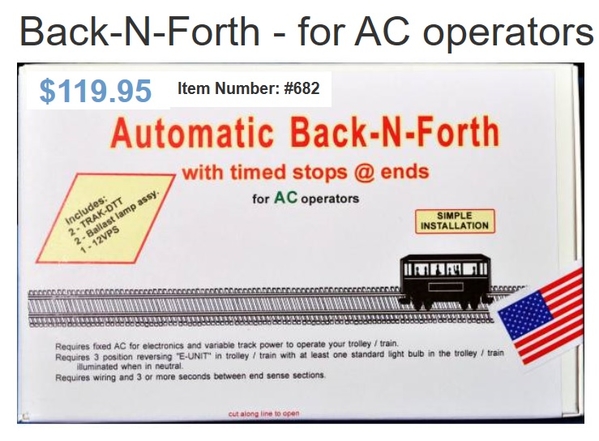

I like how you included price info. To that end, I looked up the Dallee 682 that Mike refers to above.

It also occurs to me that with low-power LED technology, it would not be a stretch to add a capacitor or similar simple circuit to keep the lights on at station stops even if there's no power on the track itself. Or for more play value maybe the LED circuit charges while running keeping cabin dark...but then lights turn on only when unloading/loading at the station! So many possibilities!

Attachments

Thanks for all your suggestions. Here’s a better description of what I’m up to. On the layout I’m building - my first since I wad a kid 70 years ago - I’m running two mailines on O gauge tubular track. I plan on adding the trolley on O27 because I need the sharper curves. The trolley runs from an urban center to a ski resort and mountain hamlet. A ZW provides conventional power to my post war equipment.

The trolley is not prototypical - just a Little bump and go thing I got for under the Xmas tree, but a quaint addition to the mountain village.

I do have the following which may help:

1. One Lionel 153 IR

2. Two dual infrared detectors model IRS-2 by Rail Tronics.

I’ve never used these. I picked them up a few years ago on ebay thinking I might someday use them.

My basic goal is a point to point run with a pause for loading unloading at each end.

will these tools work. If so how?

thank you James and all.

Several methods assume direct access to the DC motor inside the trolley. This allows direction reversal by simply reversing the DC voltage polarity on the track; we can deal with how you make DC track voltage from your ZW later. Your bump-n-go requires the mechanical bumping which moves a slide switch inside the trolley to perform this DC voltage reversal.

So the question is are you willing/able to do some minor re-wiring inside the trolley? It most likely will involve soldering which I realize is not in everyone's comfort zone.

As for your in-hand occupancy detectors, I'd think you need one on each end of the line. Hence at minimum, if using the 153 IR, you'd have to buy a 2nd one which is $30 or so. I couldn't find an online description of the IRS-2 much less a company website; these cottage-industry widgets usually come in a stapled bag with a one page "manual". If you are able to scan/photo the instructions or provide an online link to the same we can see its relevance.

In any case, the guys above have given a wide variety of off-the-shelf options. This is a problem that has been solved! I approach it as a re-invent-the-wheel exercise while sheltering in place. I think it could be done with, say, $5-10 in components/modules for a DIY enthusiast - meaning guys that turn on the soldering iron and coffee pot at the same time each morning! ![]()

Thank you Stan. I just completed the tables and am running the wiring. By tomorrow I plan to attach the table tops and begin the land forms. Then the two mainlines will be completed. The trolley will be last.

Along the way I’ll send you the info about the “stapled in a cellophane bag widget” (good description).

i don’t understand the need for DC conversion. The trolley bumps and reverses fine. I was assuming I could somehow stop the trolley and then move it forward an inch or so to bump and reverse.

You are right, I do have an aversion to soldering. But if necessary, there’s always a first time!

Regarding DC conversion. Somewhere in the trolley is a so-called bridge-rectifier component - thumbnail sized and with 4 terminals. This takes the 2 wires with the AC track voltage and converts it to 2 wires with a DC voltage. The trolley motor operates on DC voltage. Reversing the DC voltage (i.e., swapping the two wires going to the motor) reverses the motor direction. The bump-n-go trolleys have sliding electrical contacts that perform this swapping ping-pong style when hitting the bumpers.

So. Several of the methods proposed perform the DC voltage reversing on the track voltage itself. For this to "work" you have to then bypass the bridge-rectifier in the trolley so that the track voltage is directly applied to the motor. In these direct DC methods, the sliding electrical contacts are not used and the trolley does not have to bump at each end. But bypassing the bridge-rectifier more than likely requires soldering, re-working potentially short and tiny wires so it can be a nuisance. And you'd have to post several close-up photos so one of us can identify the necessary modifications...and of course trust that we don't abandon you along the way with everything dis-assembled should problems develop!

-----

OK, I'm game to explore using the trolley as-is using the method you propose. A couple questions first and I'll explain my thinking.

1. For the intended speed of operation (determined by your throttle setting), how quickly does the trolley stop when you instantly remove track power by, say, pulling the plug to the track? I suspect this will be something like 3-6 inches but try it a few times at a few different suitable speeds.

2. Say the trolley is stopped near the bumper but has NOT yet bumped to reverse. If you instantly apply track power by, say, connecting the track wire to the transformer (transformer being already set to the desired operating speed), how close can the trolley be to the bumper? In other words there will be minimum distance for the trolley to accelerate and develop enough momentum to reliably activate the sliding electrical contacts which reverses the DC voltage to the motor. What is that distance? I suspect it will be more than 1" but it is what it is.

So expanding on your idea,

Trolley approaches end of line. Infrared sensor (possibly the IRS-2 if we figure it out) detects trolley and triggers a relay. Relay removes power to entire track for 30 seconds. Trolley stops before end of track but far enough away from bumper per question 2 above. Power is restored, trolley accelerates to speed, bumps and reverses, goes other direction passing detector. But in this case the trigger is ignored (more on this in a second). Trolley reaches other side and a 2nd infrared sensor performs same operation. In fact the same relay module can be used if either detector can trigger the module.

So the man-behind-the-curtain is some method to disable or ignore the infrared sensor for some length of time after stop so that the 30 second interval does not immediately start again. Well, there are low-cost timer modules that have this kind of timing capability. We can get into specifics but first let me know if I'm heading in the right direction!

Attachments

Attachments

Stan2004. Even with our stay in place order, this project is taking longer than I had hoped. I will get back to you

Is the trolley recent? I'm not sure Stan has the postwar version in mind. The more recent versions use a small dc can motor; the pw is a universal open frame ac motor.

Adriatic posted:Is the trolley recent? I'm not sure Stan has the postwar version in mind. The more recent versions use a small dc can motor; the pw is a universal open frame ac motor.

What I have in mind is a method to use his trolley as-is. All electronics or modifications will be external to the trolley. It will use the existing bump-n-go mechanism for reversing. In other words, it doesn't matter if the trolley guts are a DC motor, an AC motor, a mouse running on a wheel, a rubber-band, or fill-in-the-blank. ![]()