I purchased approximately 14 pairs of Lionel "O" Scale 2 Spring Sprung Bettendorf Trucks and 3 Spring Sprung Roller Bearing Trucks and put them in a closet and forgot about them around the early 2000s. About 2 years ago, I had need for several of the Roller Bearing Trucks and got them out of the closet. Yep, 5 pair of the roller bearing trucks were disintegrating. Anything that was made out of pot metal was falling apart. I called Lionel up in North Carolina and talked to someone in the warranty dept and the person told me "it was out of warranty". I asked would they exchange them -- the answer was NO! I asked if they would fix them, I would pay the bill for it -- The answer was No! That was the last time I ever bought a Lionel Product.

Added this on 07/07/2020--I received an email from someone saying that I was bashing LIONEL with my commentary above. This is the honest truth what happened when I called Lionel's warranty department about 2 years ago. I was not the one at fault, this was Lionel's Problem in which they put zinc rot car trucks onto the market. The sad thing about this is that Lionel uses Chinese Companies that could not care less if there pot metal is contaminated with lead or zinc.....and we the buyers get the Rot if we buy something contaminated. The same thing goes for the MTH stuff that comes from China. So what are you going to do? Examine your Chinese made trains for zinc rot every week?

I have had trucks from MTH that had Zinc Rot also. I had sold several "O" Scale UP Tuscan Gondolas to a gentleman and he reported to me that several of the Pot Metal Coupler Armatures on some of the cars were disintegrating. Lucky, I had several extra of the trucks and sent them to him.

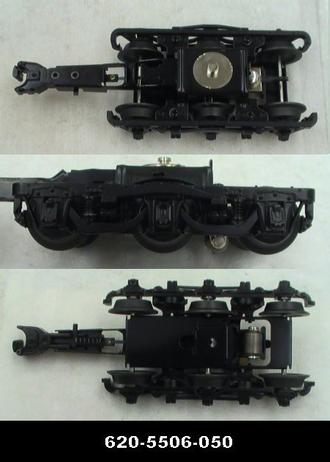

The latest incident of Zinc Rot took place about 5 weeks ago. I had bought a N&W Railking Streamline J and it had a beautiful die-cast engine and tender plus 4 freight cars. I just took it out of the box after purchasing the set way back around 1998. The engine had a small problem with the smoke unit, but the tender was a disaster. I wanted to put a new battery in the tender and took the item apart. I got the metal base off the tender, separated from the top shelf with no difficulty. I checked out the tender and as I held it in my hand, one of the side frames to one of the trucks broke off. Then another side frame broke off and finally all 4 side frames broke off. I just sat there and looked in dismay at the mess that just occurred. I got out my Trusty Dollar Store Tube of superglue and worked for over 4 frustrating hours, but I was able to get the trucks back together. I took the engine/tender over to a gentlemen that use to repair trains at Davis Trains (now defunct) in Milford, Ohio. He told me that he has seen a lot of the dreadful zinc rot over the years. He sees a lot of Railking "stuff" and he will try to get me some new side frames.

Lesson Learned by these incidences......Inspect your trains regularly. The reason why we have Zinc Rot in pot metal used In our toy trains is that the country were the die-casting is done does not really care what kind of metal they use. They just take it in on recycling and could not care less if it is contaminated with zinc/lead or not. Remember, we are over 3000 miles from there country and they could not care less what is being sent to us.

I wonder if they are putting out $2000 dollar engines and sending them to the USA that have contaminated pot metal casting?

PS--Of all the Toy Trains that I have bought from South Korea, I have never had a problem with them nor had I ever had a case zinc rot.

Added on 07/07/2020 ---- The real answer to not having a zinc or lead "ROT" in our trains is to make the trucks and any extra parts of hard PLASTIC. How many people are going to visit your layout with a magnifying glass to check to see if the trucks or add on parts are made from plastic and not metal. Toy trains should be fun to operate and we should not have the worry that the side frames, coupler armatures, etc will decay due to contamination from lead or zinc. Axles and wheels of freight/passenger cars should be steel and extra add on parts should be made from durable plastic.....enough said and done --- sincerely yours railbear601