Thanks Mark! Hoping the homasote for the price is worth it in the end haha!

I think the Homasote is worth it. I'm cutting it out so it is just under track, but my track density isn't what yours is. With your layout plan, you might as well just cover the whole top with it. It also depends on how you plan to scenic the layout. Sometimes it is best to cover the whole top depending on your scenery approach.

Excellent lighting Lance. I used Homasote all around, and it is worth it. And it's fairly inexpensive. The layout and room are really looking great.

Andy

Looking good, Lance.

The lift up bridge looks great!

If the barn door type hinge for the bridge proves too wobbly, don't "give up". Just go to a common "piano hinge" (cut to length was a hack saw, etc) The width usually hold things straighter through its entire travel with zero play. Available "everywhere" from Ace to Menard's.

I've used them on large 6'x4' 1/2" & 3/4" wood cabinet doors used daily, leaned on, hung on, and otherwise abused. They are much stronger than they look, and hold the edges very well too, despite the tiny screws (drill extra screw holes and/or use longer screws if you really want to; but it's likely overkíll )

@Adriatic posted:If the barn door type hinge for the bridge proves too wobbly, don't "give up". Just go to a common "piano hinge" (cut to length was a hack saw, etc) The width usually hold things straighter through its entire travel with zero play. Available "everywhere" from Ace to Menard's.

I've used them on large 6'x4' 1/2" & 3/4" wood cabinet doors used daily, leaned on, hung on, and otherwise abused. They are much stronger than they look, and hold the edges very well too, despite the tiny screws (drill extra screw holes and/or use longer screws if you really want to; but it's likely overkíll )

I was going to do that, but I read somewhere you want the hinge point higher than the track so it doesn’t bind? It’s not too bad after I get it down in the groove when laying flat but it does still pivot just slightly. I thought I had the current one high enough but with 2 pieces of test track it still binds slightly.

Mark and Dave thanks!

@Lancer posted:

Hard to tell for sure from the pictures, but it looks like the hinge will bind after track has been laid on the table. As mentioned in an earlier post, you do need to design something so that the hinge pivot point is above the rails. Alternative is to build it as a lift-out.

I’ll be facing the same issue, but my two tracks are 6 inches apart in elevation. I was planning two bridges, whether pivoting up like yours or lift out. That’s down the road for me

I forgot about that; ours became a drop down after some finger and head injuries 🤕. (it was like a 3½-4x4' lift)

Lance, if you ever figure out how to get the track clearance at the hinge end please post some photos. On my three movable bridges, I have found I needed to have the ability to fine tune the joint areas due to wood movement and use of the mechanism. I get side to side movement and up and down movement - not a lot - but enough for an audible bump especially in a height difference. I use a combination of shims and flat head wood screws to be able to make adjustments at the joint. I found permanently mounting the track to the removable section and having an overhang so the track joint and base joint do not overlap solved a bunch of issues. Duck unders got old really quick.

@ScoutingDad posted:Lance, if you ever figure out how to get the track clearance at the hinge end please post some photos. On my three movable bridges, I have found I needed to have the ability to fine tune the joint areas due to wood movement and use of the mechanism. I get side to side movement and up and down movement - not a lot - but enough for an audible bump especially in a height difference. I use a combination of shims and flat head wood screws to be able to make adjustments at the joint. I found permanently mounting the track to the removable section and having an overhang so the track joint and base joint do not overlap solved a bunch of issues. Duck unders got old really quick.

I ended up going with a lift out. There were a few things I wanted and the lift out better suited me. I know lots of folks say the “hinge point” has to be above your rails or higher per say to make it not bind.

I also didn’t want to have a connection I had to manually unhook so I’ve got creative with dowels and my 3D printer and have been working on a disconnect I think will work great. It’s not wired up in the photo yet but it makes the connection snug yet still can lift out with minimum effort. Put in some micro switches on each side aswell to kill the oncoming track power in case the bridge is not in place.

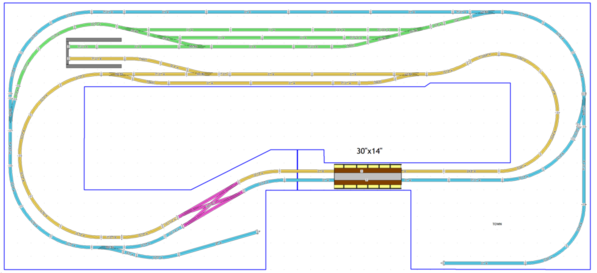

Last but not least, here is the updated track plan as the table sits. I ended up wanting a town so I changed a few things around thus had to change the bridge design slightly.

Attachments

Lance, The lift out looks good. Will you provide a place to sit it down, or just hold it until you are through and put it back in place? I'm contemplating the liftout may be better for the me, the carpentry challenged modeler. ![]()

Thanks Mark, I have room under the table over in that area I may build a small shelf to sit it on when not in place.

Tonight’s update. Waiting on some switches to show up later this week so doing what I can while waiting on them. I finally got the bridge how I like it and started on some power routing. I even had some help from my Local Hobby Shop owner for a bit today which helped out tremendously for an extra set of hands.

Attachments

Lance, The track you have done so far looks great! The bridge over the entryway looks good, and should be sturdy for moving back and forth.

Wow! A hobby shop house call!!! That's great! Reminds me of the doctor making house calls when I was little. Yes, I can remember that! ![]()

Got some more track down. The outside loop is finished mostly besides a siding. My switches showed up today so only ones I am missing are the yard switches. Working on the inner loop currently. My wire shows up tomorrow so I will be able to start putting in some wire drops here soon. There will be a 1/2 inch or so lip from a 1x5 or 6 eventually so don’t be too concerned about the one siding that is near the edge.

Got some more track down. The outside loop is finished mostly besides a siding. My switches showed up today so only ones I am missing are the yard switches. Working on the inner loop currently. My wire shows up tomorrow so I will be able to start putting in some wire drops here soon. There will be a 1/2 inch or so lip from a 1x5 or 6 eventually so don’t be too concerned about the one siding that is near the edge.

I forget who mentioned it but the small cut off saw from Harbor Freight has worked awesome with cutting track. Really beats a dremel and I would recommend it to anyone looking at making cuts. With a coupon I think I walked out the door minus the blades for $35 for the saw. It is a bit loud but well worth it!

Attachments

Lance, The layout is looking better and better all the time. I should have bought one of those saws.

It’s really coming along nicely, always fun when a vision takes shape.

I was finally able to get some train room time this past weekend. Finished up the bridge wiring today and happy to say I have a fully functioning outside loop. The test engine is the NYC locomotive I got with my first Lionel set when I was 4 and have hung on to it ever since. Want to say that’s what got me into trains in the beginning lol. Here’s a quick video of the loop around. Going to be working on getting the yard laid and wiring up the switches and inside loop. Also working on getting the transformer stand with the DCS system setup. Thanks!

Attachments

Looking might fine.

That’s a nice run, Lance!!

Yessir! Trains runnin'!

Sound level is acceptable...

Got the DCS and z4000 hooked up this evening so had to break out a few of the fun toys and run them around. I know scenery and skirting will eventually help but not sure if I did something wrong with the homasote or what but it’s still a bit noisy in the room. It’s acceptable but something I may look more in to.

I noticed too some of my Menards cars aren’t liking the Ross Switches. A few of them throw sparks going over a few switches but none of the Lionel nor MTH cars have any problems.

Attachments

Some folks add cord, foam or rubber roadbed. Hard to tell how noisy it is on the video given the engine sounds.

Lance, Layout's looking really good. Liked the videos. You must be a steel guy too. Love that bridge and that 4 way X over. I have the same debate going on - lift out or tilt up. Keep us posted on how ur lift out design functions for you and am also curious how the 4way runs once ur running over it. I know you've prob been asked this before but what brand / type of lighting are u using: lithonia, juno, Hbay???;; GU10, Led, Halogen, ??? I'm about to purchase track lighting for our train room and want it to be sufficiently bright as well have a good turndown on dimming.

@DoubleDAZ posted:Some folks add cord, foam or rubber roadbed. Hard to tell how noisy it is on the video given the engine sounds.

@TomSuperO posted:Lance, Layout's looking really good. Liked the videos. You must be a steel guy too. Love that bridge and that 4 way X over. I have the same debate going on - lift out or tilt up. Keep us posted on how ur lift out design functions for you and am also curious how the 4way runs once ur running over it. I know you've prob been asked this before but what brand / type of lighting are u using: lithonia, juno, Hbay???;; GU10, Led, Halogen, ??? I'm about to purchase track lighting for our train room and want it to be sufficiently bright as well have a good turndown on dimming.

Dave- was thinking I may run cork now. Not sure yet.

Tom- Thanks for the kind words! Yeah I’ve been rough drawing up an idea for a blast furnace/ steel mill area. I will post some more pictures when I get some of the lift out design. I am still tweaking a few of the tracks on it. I actually 3D printed a piece so no wires have to be disconnected when removing. The lights are whatever was clearanced from Menards haha. The GU10 bulbs that came with them put off too much heat and were a too warm of a color so I switched to dimmable LED equivalents in a cool white color. I’ll attach what bulbs I used down below. The dim function works great on them and I ended up getting some smart dimmer switches off Amazon so I can control them via my phone or Alexa.

Attachments

Lance,

I don't recall the layers on the former layout. That was quiet, if I remember correctly.

The quiet formula is 3/4" ply ( 7 ply) , Midwest cork and Ross, GG or Atlas track.

You will get a noticeable improvement slipping some Midwest cork under the track.

Also, check the wheel diameter and if the axles or uncoupler boxes are hitting the center rail on the switches to spark.

Lance, I agree with Carl on the use of Midwest cork. I've used it since my HO days. In fact, I bought another box along with 3 Ross switches for my build on Wednesday at my LHS, CT McCormick Hardware in nearby Zelienople, Pennsylvania. I had another good chat with Jeff McCormick who now in his 50s has carried on his father's tradition selling O gauge trains in abundance at his full service hardware store.

Thanks Carl and Mark. I’m running to my LHS today to get a box of cork and experiment. If I remember I used 3/4 ply and cork on the last layout. It was much quieter. This time is 1/2 inch topped with homasote. Funny you mention that Mark, I actually got all my switches from Jeff. Very nice guy!

That sounds great, Lance. Did you order over the phone, or do you live close enough to stop in Jeff's store?

Nope I’m over in Indiana so ordered over email! Wish I lived close enough to go into the store and check it out tho.

I used to go past his store every couple weeks visiting my aunt in a personal care/nursing home a few blocks away. Wednesday was the first I had been by since she passed on in March. I have ordered online, called, emailed, and visited the store. Any way you do it, Jeff is right on top of it!!

Lance,

Let the good times roll(pun intended). I know it feels good to finally run trains. The NYC ran great and easily went through the crossover. I envy you guys who actually have your childhood trains. I broke all of mines within a week or two of having them. I have purchased a few of those sets as an adult and will eventually run for nostalgic reasons. Anywho, looking forward to more progress.

Mark, your story about the hardware store reminds me of when I was a child. I went into a hardware store with a friend of the family and to my surprise there was an entire section of trains. I was in a state of shock. I think that store had more trains than both local hobby shops. I eventually got one of the Kline sets for Christmas and yup you guessed it, it was broken within weeks. I honestly can't remember what I did to them. If I only had someone around that could've shown me how to take care of them. Grandma just bought them but that was extent of nurturing the obvious interest of mines. Fun times!

Dave

Lance!

I just found your post and I love what you are doing.

I myself have just gotten back into the hobby after 9 years, several job transfers and multiple moves.

I now have room for my trains!

Can you tell me why you have laid hemostat on your bench work? Is it just for sound absorption? Are there other reasons for when it is time for landscaping?

I look forward to hearing your thoughts, as well as your progression in your train room.

Richard

@1Irishrover posted:Lance!

I just found your post and I love what you are doing.

I myself have just gotten back into the hobby after 9 years, several job transfers and multiple moves.

I now have room for my trains!

Can you tell me why you have laid hemostat on your bench work? Is it just for sound absorption? Are there other reasons for when it is time for landscaping?

I look forward to hearing your thoughts, as well as your progression in your train room.

Richard

Homasote has been used quite a bit thru the years of model railroading and yes for sound absorption. So far I am pretty happy with the decision to use it. Thanks for the kind words and good luck on your adventure!

Lance- the layout is coming together nicely. I didn't notice the noise on the video. It may quiet down as you build scenery. The room is very empty too which amplifies the noise.

Did you fasten the track through the homosote into the plywood? If so, the track noise will transfer through the screws.

The Menards cars have had issues with the gauge on the wheel sets recently, especially the box cars. Also check the air tank assembly on the bottom, I had to modify one or two to get enough clearance on some switches.

Keep up the good work.

Bob

Lance, Thanks for the information on the LED bulbs. Interesting thing about the color. We're going to have 3 penninsulas and i'm planning on putting a track over each penninsula with 3 to 4 light heads per track and was concerned with having enough light and throwing off too much heat. We are also considering installing a ceiling fan to help with engine smoke, room air movement, heat dissipation, etc. We talked about a small exhaust fan but can't easily install due to solid concrete foundation walls & brick exterior. Closest Menards around here 1.5 hrs away (Bought a flat car there w the black hawk on it.) The homosote: We've always used homosote (1/2"), however on our test layout (in Georgia) my son has been experimenting with how we anchor down the track. I'll be talking with him this weekend, but i believe he's only using 1 screw per sec of track that goes all the way into the plywood. The others 1-3 screws just go into the homosote, so we're running trains to see if these stay secure. This is due to the forum comments about sound transfer through the screws. (Note: we are using SuperO track). I'll get back to you with specifics. Oh, we are installing a drop ceiling in the train room - with 2x2 panels that are rated excellent sound deadening / absorbtion per armstrong. #928 panels i believe.

Weirton Steel - '73-'04 Oper supv - Hot Mill Furnaces

Mark, Lance, ok you guys have me curious now. CT Mccormick hardware. Zelienople bout 1.5 hrs from here. I'm gonna have to go ck it out. Back in the day, our local hardware store (now a true value store) carried all the trains during the holidays.