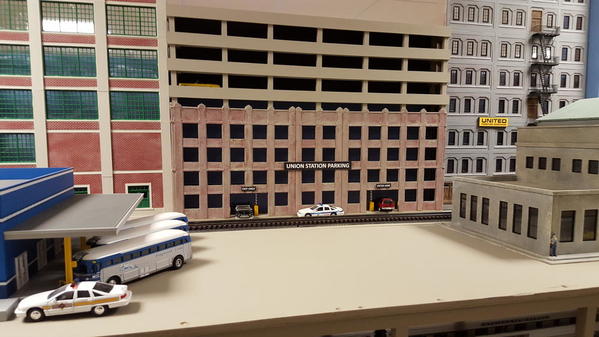

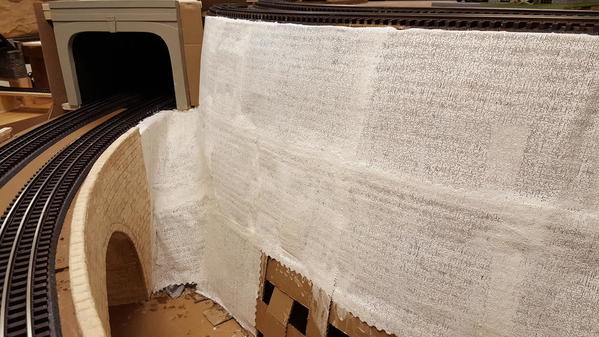

I have been posting the progress on my layout on the "What Did You Do on Your Layout" thread, but I was asked to start a new thread this time. My son and I have been working on getting my fascias installed. We left the hardest one to last which was the one around a tunnel. This tunnel you enter from the left hand side of my curved stone arch bridge. It is about 12 feet long and has my double-track mainline running through it. Today we finished putting the top on the tunnel. Access to the tunnel will be via a lift-out section on the far right side and by the sides in the balance of the tunnel. Here are several pictures of the almost finished top.

Another area we worked on was adding plywood sections to the Illinois side of my Mississippi River valley to shape the bank in preparation for plaster work. We also had to redo and replace part of the fascia here to show the correct reveal for the river bank. Here are a few pictures of this area.

I can't thank my son, Jim, enough for all his hard work the last few days on the layout. He has made some impossible jobs go smoothly and get done. Building new control panels is the next major job for the layout and he has begun that process.

Art

FrankM. IMO.

FrankM. IMO.