... There is probablya dozen ways to accomplish my goal.

Or more!

So this being a discussion forum, here's my plan-A, plan-B approach.

Plan A.

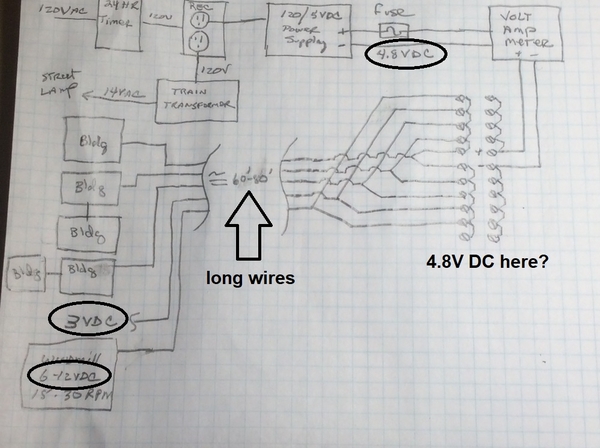

1) Check your 5V DC power supply. Does it have an adjustment control? Usually these so-called "open-frame" supplies allow you to adjust the output voltage by, say, +/-10%. In other words, by turning a small adjustment knob you can set the 5.0V (nominal) output to 5.5V (+10%). I don't like how you only get ~4.8V DC out of your 5V power supply! If as you look at it you see the nameplate spec on how many Amps/Watts your supply can put out, then please post it. It looks like you have maybe a 5V, 3 Amp supply (5V x 3A = 15 Watts) but hard to tell.

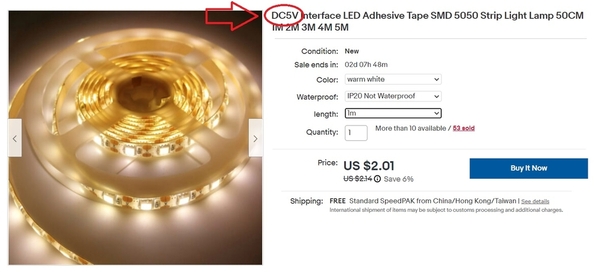

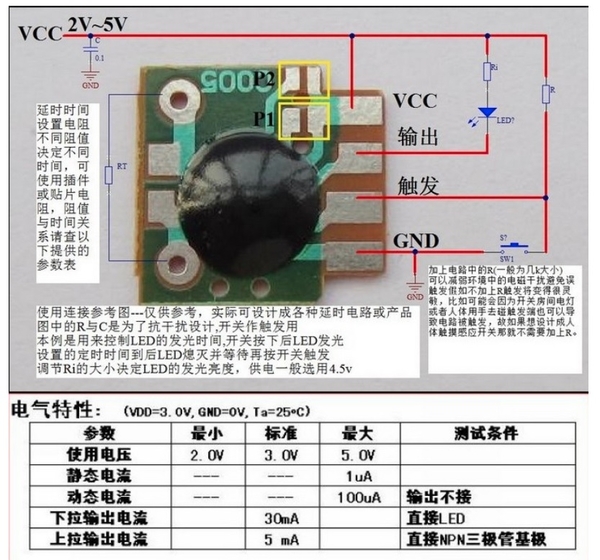

2) If your supply can be adjust to, say, 5.5V DC, then I believe you can send 5.5V DC up to the shelf and have enough voltage (after wire drop) to adequately illuminate 5V LEDs. What do I mean by 5V LEDs? This is the key. As MED points out, you can buy pre-wired 5V LEDs; these have built-in resistors so that the LED itself sees a suitable (safe) voltage when you apply 5V to the wire terminals.

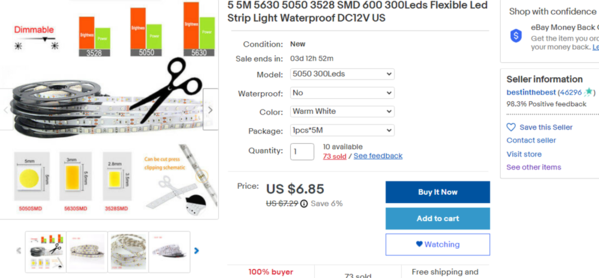

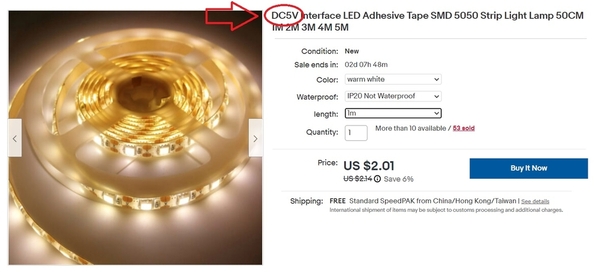

If I were doing it, I would simply use 5V LED warm-white strips. These have the "built-in" resistors so you can safely apply 5V directly to the LED. You should expect to pay at most, say, 5 cents per LED.

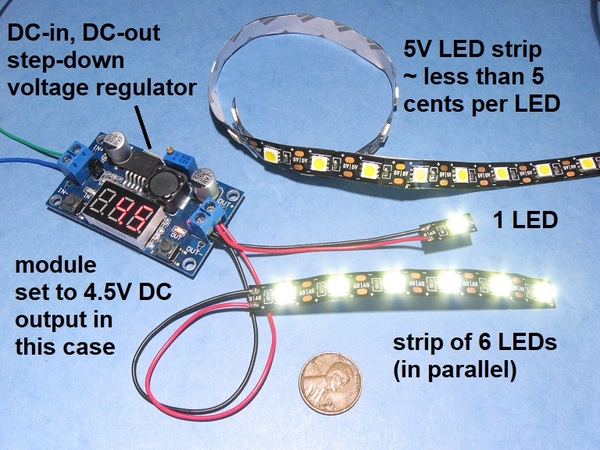

Again, in the plan A/B school of thought, you can try 5V LED light strips, cut-to-length, and see if you get adequate brightness with the long wires from panel to shelf. It appears you are familiar with these strip...but to summarize, you can cut them to length from a single LED to 10 or more LEDs. The strips themselves have the LEDs in parallel. Each LED is, as you note, a ~3V LED so on the strip there is a built-in resistor PER LED...so that applying 5V DC does not damage or burn out the LED(s).

Plan B.

I purposely skip over the techno-boredom about AWG 22 wire and how much voltage it "theoretically" drops over a 80 foot cable run blah blah blah. It's tedious and the theory rarely matches the reality of real wiring issues with crimped connectors, terminal blocks, and so on. And yes, this is just my opinion.

Here's what I would do.

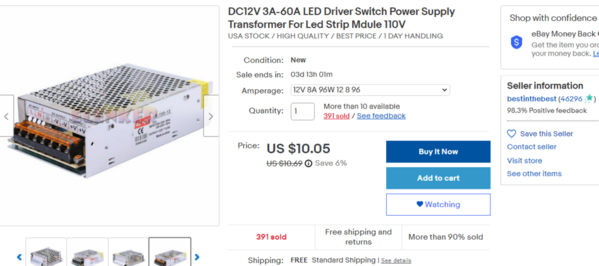

Forget the 5V power supply. Get a 12V power supply. We can get into specifics but this would be maybe $10 all-in for more power than you would ever need! And I don't know if you have kids/grandkids poking around your panel ... but I see how you shielded what appears to be otherwise exposed 120V AC line voltage! Good for you!

Go ahead and use your existing cabling.

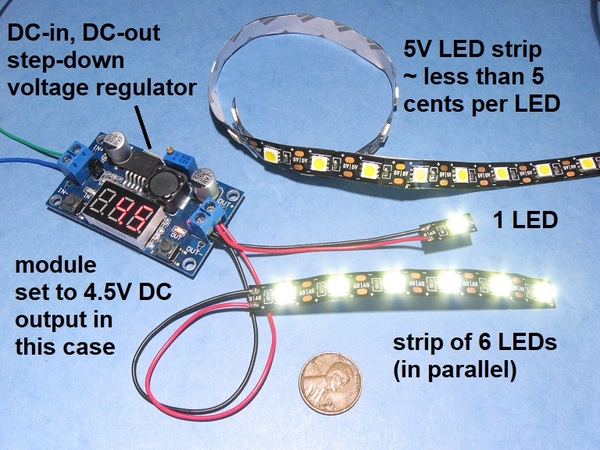

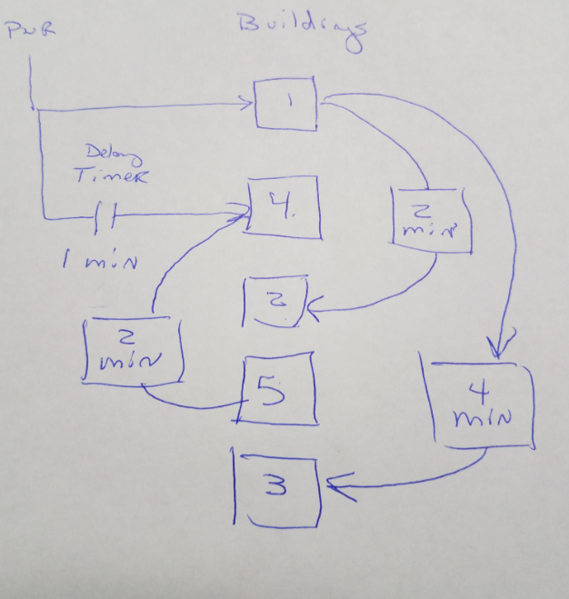

The idea is to employ point-of-use voltage regulator modules to deliver exactly 5V DC inches from your buildings. This is "classic" power distribution architecture using a "high" voltage distribution bus with so-called "local regulation." This is how it's done in the real-world! High voltage distribution with step-down to use-able voltage at the local or point-of-use (which in your case is the shelf buildings/accessories).

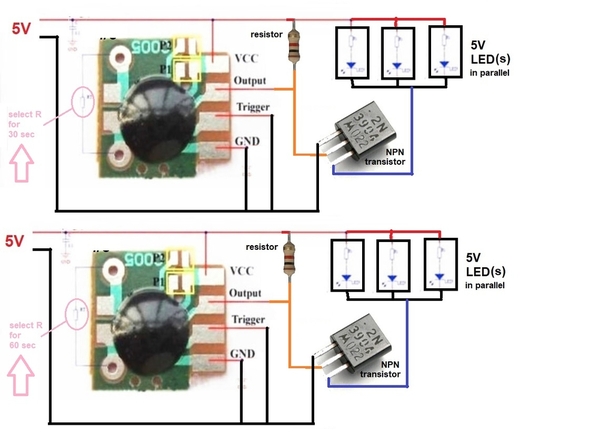

A 5V LED strip is essentially a bunch of LEDs in parallel. The above photo shows how you can cut a 5V LED in increments of one (1) LED. There is a single LED in parallel with a strip of 6 LEDs. Of course the 6 LED strip consists of 6 LEDs in parallel.

I realize you said you're not interesting in "experimenting" but only speaking for myself, I would try Plan A to see if you get adequate illumination using multiple 5V LED strip sections (in parallel) after the long wire drop.

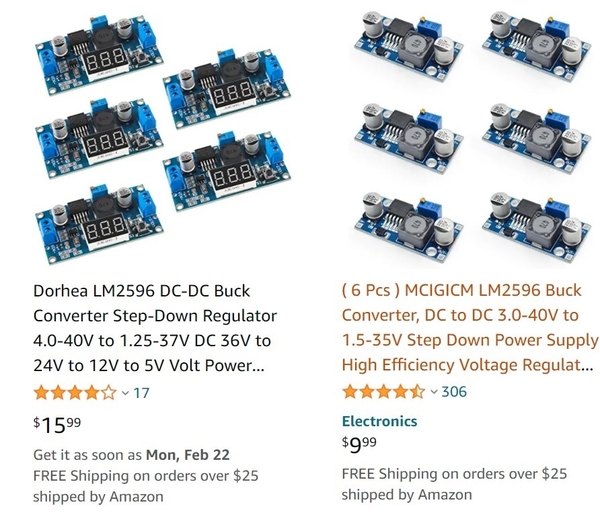

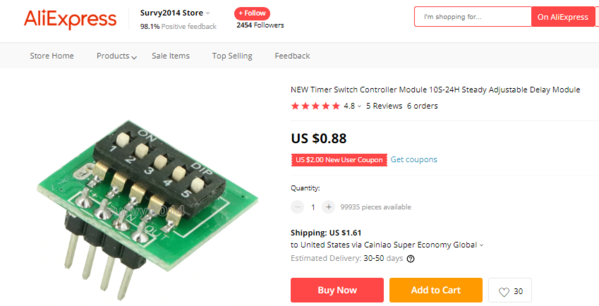

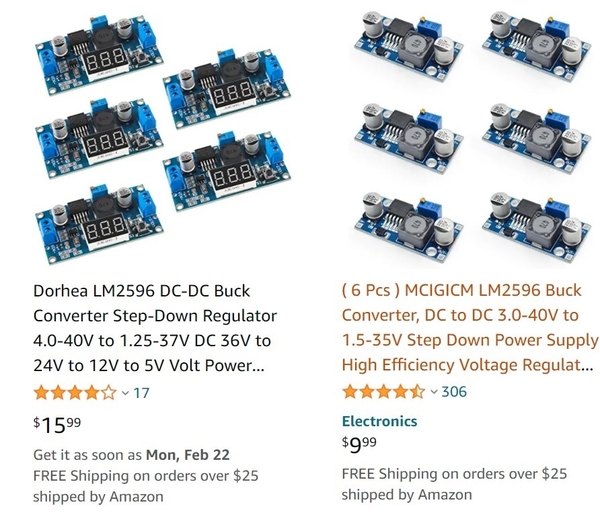

Anyway. If you step up to a 12V DC supply down at the panel, the point-of-use voltage regulator modules are less than $2...or about $3 if they include a DC voltmeter as shown above. These modules convert whatever the 12V DC voltage drops to at the end of 80 feet (or whatever) of cable to exactly 5.0V or 4.5V or whatever. And these are Amazon prices with US shipping...so if you are willing to wait a bit for Asia shipping you can save a few bucks.

In the category of "but wait, there's more" you will find a wider variety of timer modules that operate at 12V DC than 5V DC. That is, I wouldn't be surprise to learn the automotive market is the largest market for DIY timer modules!

But to be clear. Ask more questions and by all means challenge my critical thinking skills.

Hopefully others might contribute their own Plan A, Plan B, etc. !

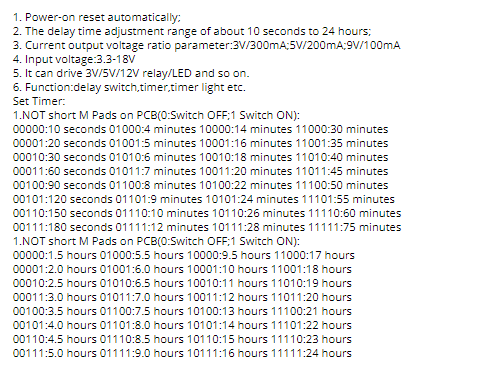

Oh. And, as others have mentioned, there are buckets of different DC timer modules that can do the job. I purposely left this out of the discussion as I don't think this is what should drive the "architecture" of your system. Cart-before-the-horse.