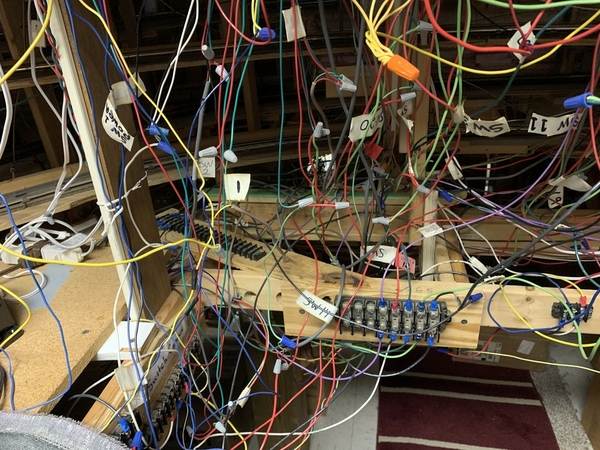

I have space right on the physical train layout outside my outer mainline for switch controllers, siding power switches, and uncoupling push buttons, and they'd be in a pretty ideal spot to manage the yard

Just wondering if anyone else has placed these devices on your tabletop layout rather than on a separate control panel? Would you be willing to post a picture? Any regrets not going with a more formal control panel like I've seen some build.

I can't mount these devices to the sides of the layout as some have done. Instead, I'm planning to affix molding to cover the homsote and plywood and then use curtains to hide space below the layout.

While basement layout 1.0 had a nice, desk-like storage cabinet for the transformers, controllers, and switches, with layout 2.0, I'd like to save the real estate. I'm planning to put the transformers on shelves below the train table.

I'm going to need 9 switch controllers (not using TMCC or DCS for these), 5 yard siding power toggle switches, and 9 uncoupling push buttons.

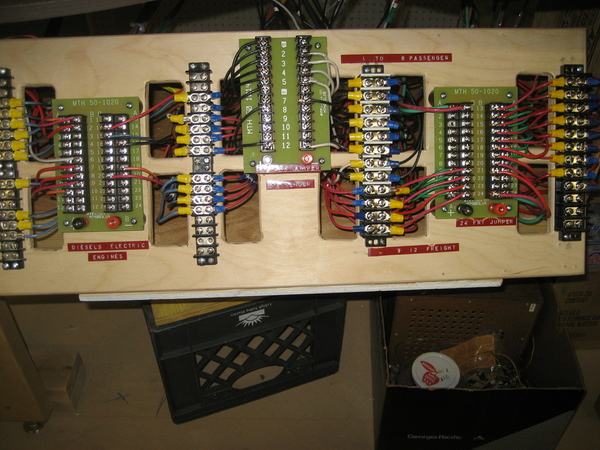

Engine service blocks

Engine service blocks