I've often wondered what the design criteria was for leading and trailing trucks on steam locomotives. Why some have a two wheel leading truck and others have a four wheel leading truck. The same goes for trailing trucks. And then there's locomotives like the S2 Turbine that had six wheel leading and trailing trucks.

Replies sorted oldest to newest

Weight.

Is weight the only reason ? It seems I've read somewhere that leading trucks helped to guide a locomotive through curves and turnouts.

Speaking of weight, it would be interesting to know how the designers distributed the weight between the drivers and leading/trailing trucks. To me, if you have a rigid piece of equipment and you want to put most of the weight on the drivers, how then is less weight placed on the trucks ?

1) more driving wheels than supporting wheels, most of the time, anyway

2) weight profile of the loco in question. Few locos have their weight equally distributed along their length (particularly, steam locos)

3) dynamic effects, particularly the tendency for traction stresses to manifest themselves at the rear drivers when starting, or accelerating a train

4) truck design is a complex subject but they do, indeed, assist greatly in improving both lateral stability (side to side movement), guiding locos into curves, and nosing (vertical oscillation caused by long overhangs or concentrated weights like cylinder castings)

Rockershovel posted:1) more driving wheels than supporting wheels, most of the time, anyway

2) weight profile of the loco in question. Few locos have their weight equally distributed along their length (particularly, steam locos)

3) dynamic effects, particularly the tendency for traction stresses to manifest themselves at the rear drivers when starting, or accelerating a train

4) truck design is a complex subject but they do, indeed, assist greatly in improving both lateral stability (side to side movement), guiding locos into curves, and nosing (vertical oscillation caused by long overhangs or concentrated weights like cylinder castings)

Thanks for the detailed explanation. When I was in college, I was learning about dynamic forces and how they affect the design of railroad bridges. It was a small part of our steel design course. These things, most of us don't give a second thought to as we drive over vehicular bridges. As I drive, I always look at the underside of overpasses and railroad bridges that pass over the highway or roads. The amount of steel put into the design of a railroad bridge must be three or four times that of a vehicular bridge.

Lehigh Valley Railroad had it right - WEIGHT.

As locomotives grew bigger, the overall weight of the locomotive exceeded what could be supported by only the driving axles. As they went faster, they needed something to stabilize the running gear to prevent "hunting" which is a rhythmic back and forth, left-right movement of the engine.

Here is a page from the NKP 765 Mechanical Package. This is just one page of an 8-page package that FWRHS provides to every railroad they operate on. This package gives the railroad the resources they need to analyze the 765's weights and clearances to be sure of where the 765 could safely operate on their railroad.

There is a lot of information there, but I have highlighted the axle loading stats in yellow. Notice that all the axles on the locomotive (except the pony truck) weigh within 5,100 pounds of each other. The lightest axle is the rear axle on the trailing truck at 61,200 pounds, while the heaviest axle is the #1 Driver at 66,300. The spring rigging, which is a series of springs, levers and bell cranks, equalizes the weights on each axle, even on rough track.

The absolute maximum acceptable axle loading on the railroads today is around 78,000 pounds. A 4-axle freight car weighing 286,000 pounds (a very common specification today) has axle loadings of 72,500 pounds. A big 6-axle diesel at 440,000 pounds has axle loadings of 73,000 pounds. Note that BOTH of these specs are far above the axle loadings of the 765.

The 2-wheel Pony Truck is needed to support the weight of the front end of the locomotive. The large valves, cylinders and the air pumps are all right up there in front. And, since the Berks were designed to run at speeds up to 70 mph, that Pony truck also stabilizes the running gear from lateral movement and guides the loco into curves at speed.

The 4-wheel trailing truck is needed to support that huge firebox. That was the hallmark of the Lima "Super Power" design - a huge firebox and boiler capable of producing 115% of what the locomotive could ever possibly use. That big firebox is heavy, and it takes a 4-wheel truck to support that weight.

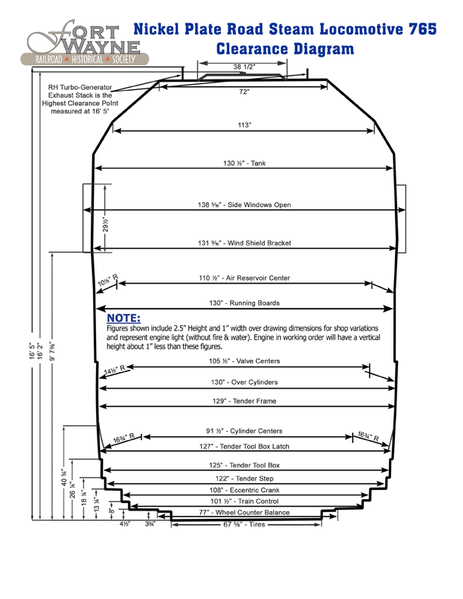

I mentioned "clearances" in a previous paragraph. Here's what the 765's "Clearance Diagram" looks like:

This is what a railroad uses to make sure the 765 will fit on their yard tracks, station platforms and under all their overpasses.

Attachments

Diagram well made. Intetesting the HP is aound 4500. This is about the same as a current AC diesel electric. But how it places the HP on the rail is vasty fifferent.

Dominic Mazoch posted:Diagram well made. Intetesting the HP is aound 4500. This is about the same as a current AC diesel electric. But how it places the HP on the rail is vasty fifferent.

Really? Why?

Dominic Mazoch posted:Diagram well made. Intetesting the HP is aound 4500. This is about the same as a current AC diesel electric. But how it places the HP on the rail is vasty fifferent.

You are correct, the power put down via a diesel electric is a lot more stable then the steam engines, more linear.

Lehigh Valley Railroad posted:Dominic Mazoch posted:Diagram well made. Intetesting the HP is aound 4500. This is about the same as a current AC diesel electric. But how it places the HP on the rail is vasty fifferent.

You are correct, the power put down via a diesel electric is a lot more stable then the steam engines, more linear.

Really? Please explain in more detail.

Hot Water posted:Lehigh Valley Railroad posted:Dominic Mazoch posted:Diagram well made. Intetesting the HP is aound 4500. This is about the same as a current AC diesel electric. But how it places the HP on the rail is vasty fifferent.

You are correct, the power put down via a diesel electric is a lot more stable then the steam engines, more linear.

Really? Please explain in more detail.

Is the power from a traction motor not more linear then the stroke of a piston?

Lehigh Valley Railroad posted:Is the power from a traction motor not more linear then the stroke of a piston?

Let's get back to basic physics: 1) a steam engine is a constant torque, variable horse power machine, i.e. the HP INCREASES as the speed increases to its maximum point, and then slowly flattens & tapers off at very great speed. 2) A diesel electric locomotive is just the opposite, being a constant horse power, variable torque machine, i.e. the stall torque is VERY high, but the HP stays the same, thus a very heavy train can be started/moved, not NOT accelerated to great speed.

Since the modern two cylinder steam locomotive has two double-acting cylinders, the so-called "linear" application of power can be felt in the train, as the train is started and during early acceleration. However, such "pulsing" has little affect on the wheel to rail adhesion, as the horse power increases rapidly.

Here is an excerpt from my book about the 765 that will be out later this year.

Comparing steam horsepower to diesel horsepower is...complicated because we are truly comparing apples and oranges. A diesel locomotive's horsepower is converted to pulling power through the electric motors. The formula Watts = Volts x Amps defines it all. In simple terms, the Watts represent the horsepower of the diesel and generator, while Volts represent speed and Amps represent pulling power. When the speed is low, the pulling power (the Amps) is very, very high. But as the speed increases, the pulling power comes down. That's why on a diesel, the ammeter reads very high at low speed and then drops off as the speed increases. Once they balance off, the only way to go faster is to increase the available horsepower. This means a more powerful diesel engine or more units on the line. That is why a 1500-h.p. SD7 and a 4000-h.p. SD70 can pull about the same train at low speed, but the SD70 can accelerate it to a much higher speed.

The steam engine's power curve, on the other hand, is exactly the opposite. A steam locomotive applies its power directly through the reciprocating engine, meaning the power is developed in pulses as the pistons move back and forth to turn the wheels. At slow speeds, those "power pulses" repeat at a slow rate and are far apart, so the power developed is not very high. For example, under 30 m.p.h., the best the 765 can do is about 2100 drawbar horsepower. But, as the engine accelerates, the power pulses get closer together and occur more often, so the power level increases. Or, said another way, in a fixed amount of time, more power pulses occur at high speeds than at low speeds. Remember that "horsepower" is a measure of how fast a given amount of work can be performed. Thus the power developed at high speeds is greater than at low speed. Eventually, even a steam locomotive's power curve will begin to fall off as the machinery reaches a rotational speed where so much power is being absorbed to turn the wheels that less is available to pull the train.

Back to the OP, regarding the lead truck, it has to do with "hunting" as Rich pointed out. A big factor in that is speed. An 0-6-0 or 0-8-0 moving slowly around a yard isn't very likely to derail at a switch. An engine going faster is going to be more likely to have a problem, so adding 2 leading wheels is going to help steer the engine through switches and around curves. The fastest steam engines were passenger engines, and they used 4-wheel lead trucks to ensure they safely negotiated crossovers and curves at high speeds.

In an engine with no trailing truck, the entire firebox has to fit between the drivers. By adding a trailing truck, the firebox can now be the full width of the engine, giving you more combustion and more power.

wjstix posted:Back to the OP, regarding the lead truck, it has to do with "hunting" as Rich pointed out. A big factor in that is speed. An 0-6-0 or 0-8-0 moving slowly around a yard isn't very likely to derail at a switch. An engine going faster is going to be more likely to have a problem, so adding 2 leading wheels is going to help steer the engine through switches and around curves. The fastest steam engines were passenger engines, and they used 4-wheel lead trucks to ensure they safely negotiated crossovers and curves at high speeds.

The other very important function that a lead or engine truck performs, besides guiding into curves & turnouts is, flange wear on the front drive wheel/wheels is drastically reduced. Even locomotives equipped with lateral motion devices would still experience excessive flange wear without any sort of lead truck.

In an engine with no trailing truck, the entire firebox has to fit between the drivers. By adding a trailing truck, the firebox can now be the full width of the engine, giving you more combustion and more power.

Rich and Hot Water, thanks, I learned something I was always curious about. I am now wondering about the axel loads on the big articulated locomotives such as the Big Boy, Challenger, and YB series.

Hot Water posted:wjstix posted:Back to the OP, regarding the lead truck, it has to do with "hunting" as Rich pointed out. A big factor in that is speed. An 0-6-0 or 0-8-0 moving slowly around a yard isn't very likely to derail at a switch. An engine going faster is going to be more likely to have a problem, so adding 2 leading wheels is going to help steer the engine through switches and around curves. The fastest steam engines were passenger engines, and they used 4-wheel lead trucks to ensure they safely negotiated crossovers and curves at high speeds.

The other very important function that a lead or engine truck performs, besides guiding into curves & turnouts is, flange wear on the front drive wheel/wheels is drastically reduced. Even locomotives equipped with lateral motion devices would still experience excessive flange wear without any sort of lead truck.

In an engine with no trailing truck, the entire firebox has to fit between the drivers. By adding a trailing truck, the firebox can now be the full width of the engine, giving you more combustion and more power.

And additional wear on the rail.

Oscar posted:Rich and Hot Water, thanks, I learned something I was always curious about. I am now wondering about the axel loads on the big articulated locomotives such as the Big Boy, Challenger, and YB series.

As a general rule of thumb, most main line steam locomotives of the modern era, tended to not exceed 68,000 lbs per axle. That said, locomotives of the C&O Rwy, tended to exceed that practice by a LOT, i.e. upwards of 75,000 lbs to as high as 80,000 lbs per axle.

One can always take the engine weight, i.e. without the tender, and divide that number by the number of axles, and you will come pretty close to the loading of each axle (sometimes the weight on drivers is a bit heavier than the weight on the engine truck and/or trailing truck).

I seem to remember a steam locomotive website that provides LOTS of information, which might answer your questions.

Oscar posted:Rich and Hot Water, thanks, I learned something I was always curious about. I am now wondering about the axel loads on the big articulated locomotives such as the Big Boy, Challenger, and YB series.

Presuming that's supposed to be a Y6 as in N&W, those things were designed to go into coal branches. I don't have the axle loadings offhand, but branchline trackage to get into coal mines is not exactly of high standard most of the time, so I'd say it's fairly low.

Remember, you can only get so high on axle loadings before bridges and things start being affected, so there were incentives to keep the weight spread out and the axle loadings as low as possible. Its somewhat counterintuitive, but its my impression that some of the big designs right around the invention of superpower steam where they were straining as to what you could do with the current technology where those numbers can get high. Early 10 and 12 drivered, non-articulated designs.

kgdjpubs posted:...there were incentives to keep the weight spread out and the axle loadings as low as possible...

Oscar posted:...I am now wondering about the axel loads on the big articulated locomotives such as the Big Boy, Challenger, and YB series.

The axle loadings on the Big Boy and other large, articulated steam locomotives would not be that much different from the 765. Big articulated locomotives are certainly much heavier than the 765, but they also had more axles over which to spread that weight.

Believe it or not the heaviest axle loading on the railroads is a 315,000 pound, 4-axle freight car. That's 78,750 pounds per axle. There are many of them out there, often loaded to capacity. No steam locomotive ever had axle loadings that high. The C&O Allegheny comes close. At 771,300 pounds on 10 axles, that's 77,130 pounds per axle.

Bridge Loading was always an issue had to deal with when operating the 765. It was not because the 765's axle loadings were too high, rather it was because the weight was concentrated in a shorter wheelbase than the typical 6-axle diesel. This has a huge effect on bridge loading.

As an example, the distance between truck centers on an EMD SD70 is just over 60 feet. The truck wheel base is 13 feet. So the total wheelbase for all six axles is around 73 feet. Most of them weigh about 400,000 pounds. That's 66,666 pounds per axle, spread over approximately 73 feet. The 765's engine wheelbase is only 55 feet, with almost the same axle loadings. That 18 foot difference makes a huge change in the bending load on bridges, especially short bridges.

Rich:

You have stated that the NKP Berkshires were designed for 70 mph. I have an underlying curiosity as to what the basis for this is as I have never seen a figure in any Lima engineering data or published material indicating the 70 mph figure.

When I was a kid the crews would tell me that they were designed for 80 and they were operated at 70 or above routinely in regular service. The section between Wallace Junction and the west side of Erie was a real racetrack for these engines. I saw them.

Indeed, 765 has been operated above 70 mph many times as you well know.

Thanks.

Jim Kreider

Rich Melvin posted:kgdjpubs posted:...there were incentives to keep the weight spread out and the axle loadings as low as possible...

Oscar posted:...I am now wondering about the axel loads on the big articulated locomotives such as the Big Boy, Challenger, and YB series.

The axle loadings on the Big Boy and other large, articulated steam locomotives would not be that much different from the 765. Big articulated locomotives are certainly much heavier than the 765, but they also had more axles over which to spread that weight.

Believe it or not the heaviest axle loading on the railroads is a 315,000 pound, 4-axle freight car. That's 78,750 pounds per axle. There are many of them out there, often loaded to capacity. No steam locomotive ever had axle loadings that high. The C&O Allegheny comes close. At 771,300 pounds on 10 axles, that's 77,130 pounds per axle.

Bridge Loading was always an issue had to deal with when operating the 765. It was not because the 765's axle loadings were too high, rather it was because the weight was concentrated in a shorter wheelbase than the typical 6-axle diesel. This has a huge effect on bridge loading.

As an example, the distance between truck centers on an EMD SD70 is just over 60 feet. The truck wheel base is 13 feet. So the total wheelbase for all six axles is around 73 feet. Most of them weigh about 400,000 pounds. That's 66,666 pounds per axle, spread over approximately 73 feet. The 765's engine wheelbase is only 55 feet, with almost the same axle loadings. That 18 foot difference makes a huge change in the bending load on bridges, especially short bridges.

Informative info Rich. Thanks for posting. From my structural steel, concrete and wood courses, we learned about concentrated and uniform loads. The 765 load you referred to is simply a moving concentrated load. But what isn't quite so simple is designing bridges for dynamic loading, such as a train moving over it.

Jim Kreider posted:Rich:

You have stated that the NKP Berkshires were designed for 70 mph. I have an underlying curiosity as to what the basis for this is as I have never seen a figure in any Lima engineering data or published material indicating the 70 mph figure.

Just a generalization, Jim. Not a hard spec.

Hi fellas,

Some earlier comments in this thread reminded me of an old railroad adage: “A steamer can pull what it can’t start, a diesel can start what it can’t pull.”

Rich:

You would make a good teacher......!

in the discussion of leading and trailing trucks, I can give an example of some real world consequences.

This locomotive was built by H. K. Porter Co as an 0-4-0 saddle tank switching engine. When I caught up with it it had been converted into a 2-4-0 and tender. It was used by the Laurel Highlands Railroad in Western PA, which was a tourist railroad, in the late 1990's / early 2000's. The man responsible for the conversion told me he actually scaled the up the plans for the guide truck assy from live steam locomotive designs. Since we ran in tourist service there was a whole lot of pull the train out and push the train back type of service, with no turning facilities. The result was that when going forward the guide truck did a pretty nice job keeping the engine in the middle of the rails, but while reversing the rear driver flanges were rubbing hard, all the time. The rear driver set needed new tires about twice as often as the front driver axle, because the rear driver flanges would wear out quickly.

Attachments

Dominic Mazoch posted:Rich:

You would make a good teacher......!

Thank you, Dominic.

Now I have heard the front truck called the front, lead and engine truck. Dome of the names I have read on this forum. From people in the know. So, what is it called?

Dominic Mazoch posted:Now I have heard the front truck called the front, lead and engine truck. Dome of the names I have read on this forum. From people in the know. So, what is it called?

Leading truck, pony truck, bogie and trailing wheel. I think they’re all correct.

- Pony truck

- Lead truck

- Engine truck

All these are acceptable names. The term “bogie” was never popular in the US. It was used in the UK.

Trailing truck is the only name I’ve seen used for the truck order the firebox. I have never seen the term “Trailing wheel” used.

To add a bit to what Rich just posted:

1) A general rule of thumb was, single axle lead trucks were referred to as either a "Pony Truck" or a "Lead Truck".

2) A two axle leading truck was generally referred to as an "Engine Truck".

3) No mater how many axles, a trailing truck was always referred to as a "Trailing Truck".

Hot Water posted:To add a bit to what Rich just posted:

1) A general rule of thumb was, single axle lead trucks were referred to as either a "Pony Truck" or a "Lead Truck".

2) A two axle leading truck was generally referred to as an "Engine Truck".

3) No mater how many axles, a trailing truck was always referred to as a "Trailing Truck".

Did Southern Pacific alter their terminology when referring to their Class AC-12 Cab Forwards?

TM Terry posted:Hot Water posted:To add a bit to what Rich just posted:

1) A general rule of thumb was, single axle lead trucks were referred to as either a "Pony Truck" or a "Lead Truck".

2) A two axle leading truck was generally referred to as an "Engine Truck".

3) No mater how many axles, a trailing truck was always referred to as a "Trailing Truck".

Did Southern Pacific alter their terminology when referring to their Class AC-12 Cab Forwards?

No, why would they? The truck under the cab, was indeed the "Engine Truck" on the 4-8-8-2 cab forwards, while the truck under the cab of their 2-6-6-2 and 2-8-8-2 cab forwards was the "Lead Truck" or "Pony Truck". The SP did however, have lots of difficulty designing and redesigning that leading truck to actually perform as required, instead of simply supporting the weight of the cab & firebox, as all other "Trailing Trucks" do.

That is informative. Thanks.

Thanks Hot. I never thought about having to re-design a "trailing truck" to function as a lead truck as well.

Very informative thread. I've always wondered about the transfer of power via piston driven engine vs electric traction motor (diesel) and this thread answered a lot of questions.

One thing I'm curious about. steam engine vs diesel engine moving the same long train from a dead stop: with the steam engine, I would imagine that you can apply more pressure to move the pistons as in hotter fire and opening the valves more but then you will overcome the friction of the rails and start spinning the drivers and once that happens, you lose most all currently stored effort. But with the diesel engines, as far as I can tell, could you run the diesel engine at full max output to the generator, generating the most about of available amps yet the electric traction motors won't be as apt to slip since there is no direct mechanical connection between the diesel engine and the electric traction motors to prevent slippage of the electric traction motor drivers?

bobotech posted:Very informative thread. I've always wondered about the transfer of power via piston driven engine vs electric traction motor (diesel) and this thread answered a lot of questions.

One thing I'm curious about. steam engine vs diesel engine moving the same long train from a dead stop: with the steam engine, I would imagine that you can apply more pressure to move the pistons as in hotter fire and opening the valves more but then you will overcome the friction of the rails and start spinning the drivers and once that happens, you lose most all currently stored effort.

One key piece of physics that most folks overlook is, a steam engine is a "heat machine", i.e. it is the HEAT of the steam that does the "work" within the cylinders. The hotter the steam temperature, the greater expansive force on the pistons.

But with the diesel engines, as far as I can tell, could you run the diesel engine at full max output to the generator, generating the most about of available amps yet the electric traction motors won't be as apt to slip since there is no direct mechanical connection between the diesel engine and the electric traction motors to prevent slippage of the electric traction motor drivers?

Nope! When starting with a diesel electric, the Engineer must ease the power slowly & smoothly, otherwise the couplers may break in the train, and/or the traction motors will cause the driving wheels to slip (just like the steam engine). Even though diesel electric locomotives have a pretty sophisticated wheel-slip detection & correction system, the wheels can still slip, thus unloading the main generator.

Several years ago, someone (maybe on this forum) explained the key difference between steam and diesel this way: "A steam engine gives you constant torque and variable horsepower. A diesel gives you constant horsepower and variable torque."

Tom Warger posted:Several years ago, someone (maybe on this forum) explained the key difference between steam and diesel this way: "A steam engine gives you constant torque and variable horsepower. A diesel gives you constant horsepower and variable torque."

Did you read this entire thread? I posted exactly that information about 8 days ago, i.e. near the top of this thread.

I apologize for the newbie error. I did not follow the thread back far enough. Lesson learned.