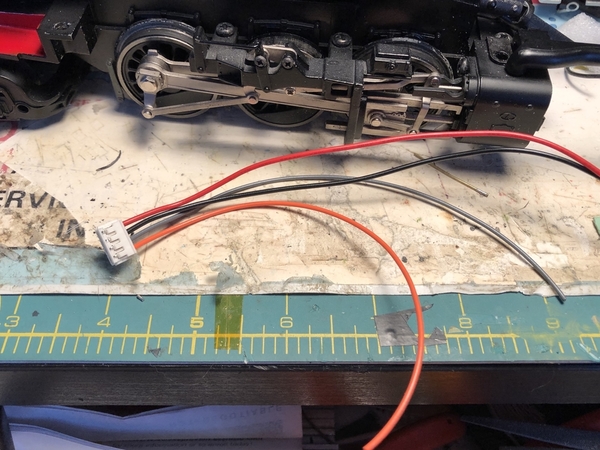

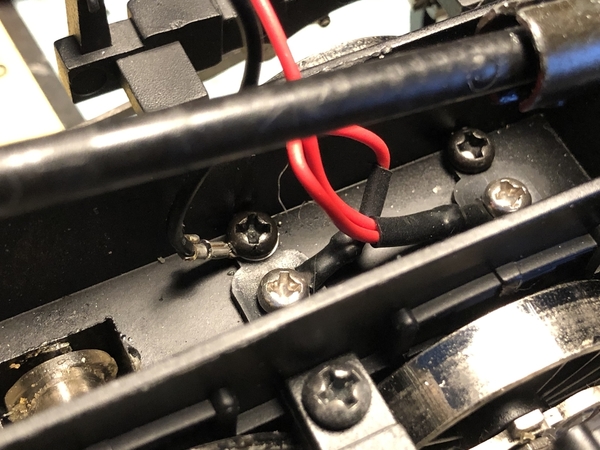

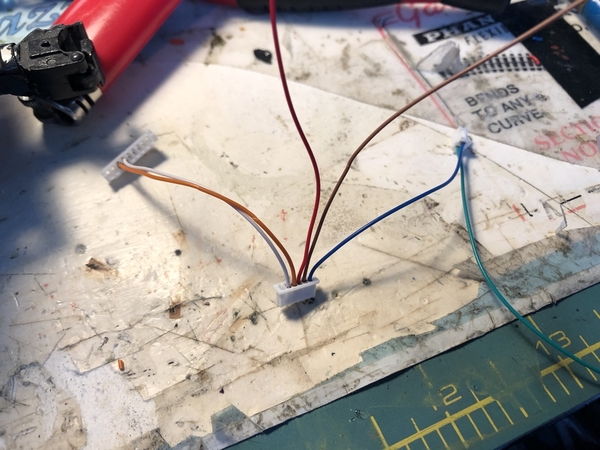

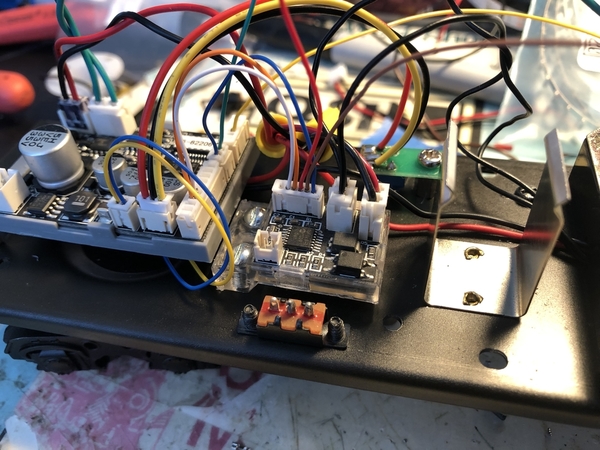

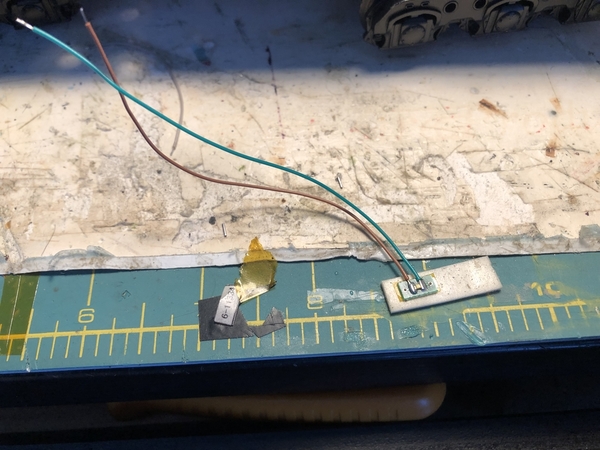

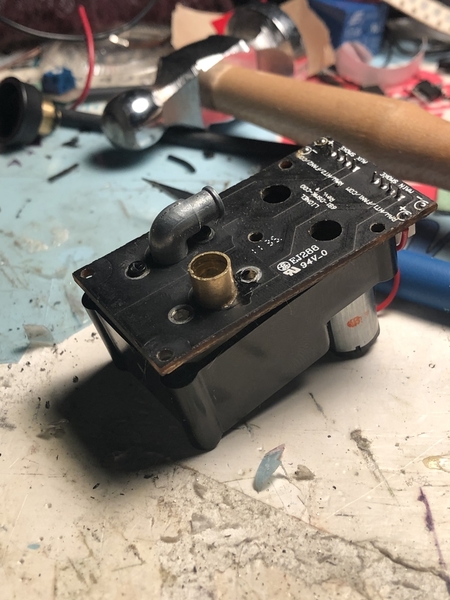

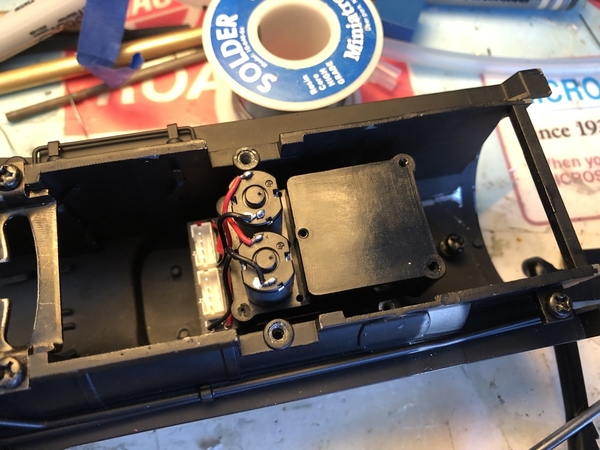

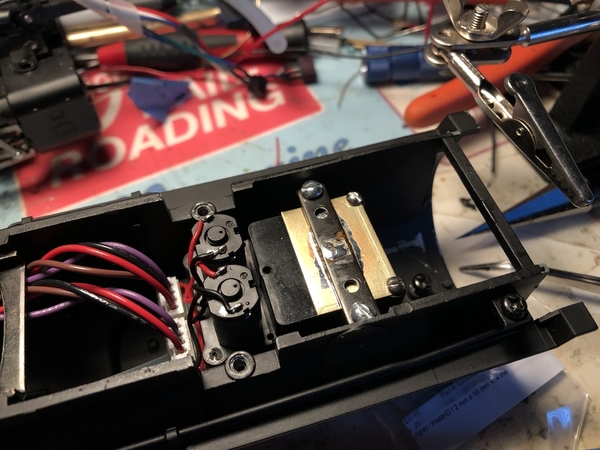

So far I’ve converted only two loco’s to Legacy an early Lionel AC-9 , and a 3rd Rail T&P 610. I’ve been promising this build for about 2+ years now. I had great success with my early AC-9 conversion. Ive been so busy with other peoples items I haven’t had any time to “clear my desk” and start work on this. But that ends now. This will be the First Scale Lionel Class A with Legacy in existence (to my knowledge) it will have full Legacy sound and features. This includes whistle steam and possibly a swinging bell (which I don’t believe is “prototypical”) I have had a lot of time to think on how to approach the installation and its pretty much the same as my AC9 project in that respect. The real hurtle will be adding the whistle steam feature-ill have to clearance the shell, drill some holes, and route plumping which if I mess up will be a costly mistake. I will be using a Dual Smoke Unit at this point in time. Another hurtle as always is building the harness for the loco, making a clean install using factory style plugs and crimped ends. I’m really excited to get this project rolling.

I did ask on the forum before if people would want this conversion on their own model. You can wait and see how this project turns out. You can always contact me via email about the pricing, FYI... Lionel most likely will not reproduce the Class A. They would have to start from scratch, create new tooling and we all know how often Lionel does that...

Follow me on this adventure!

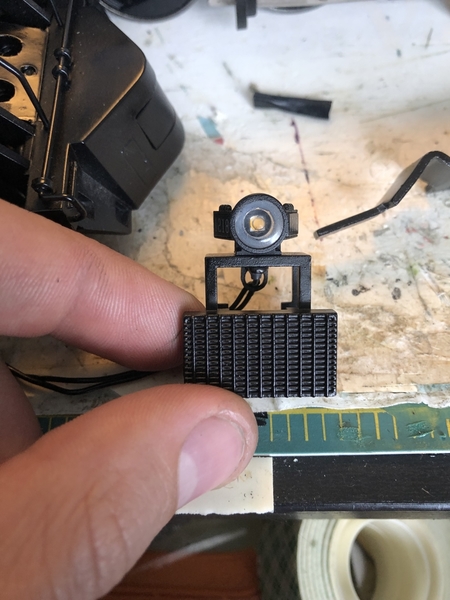

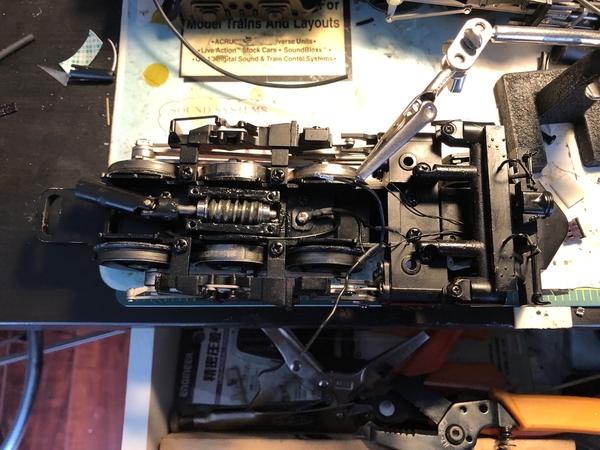

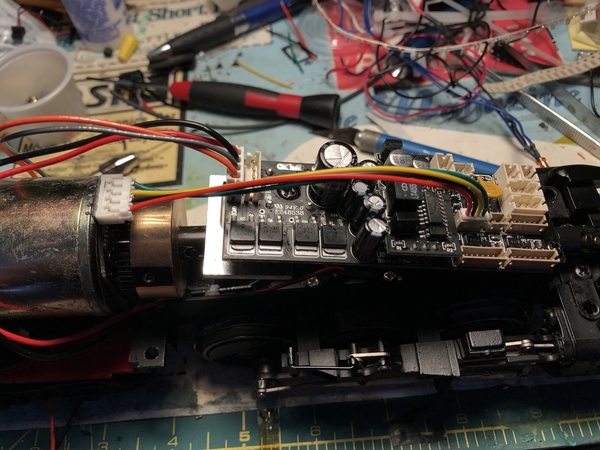

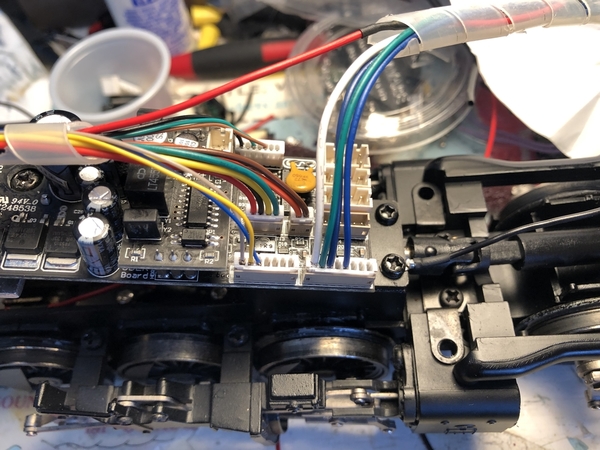

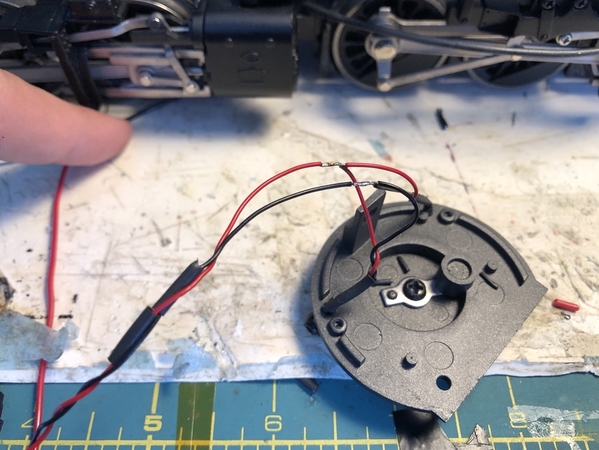

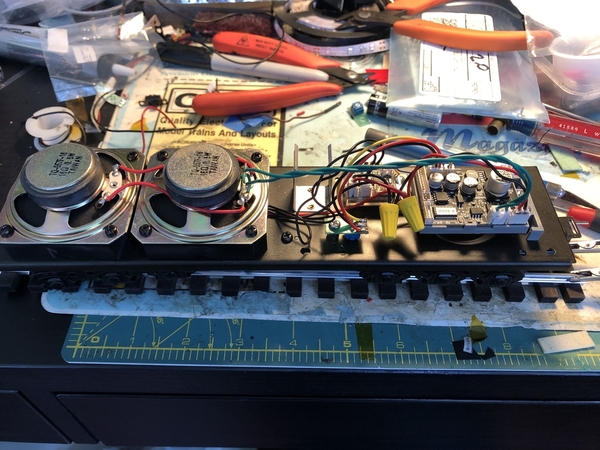

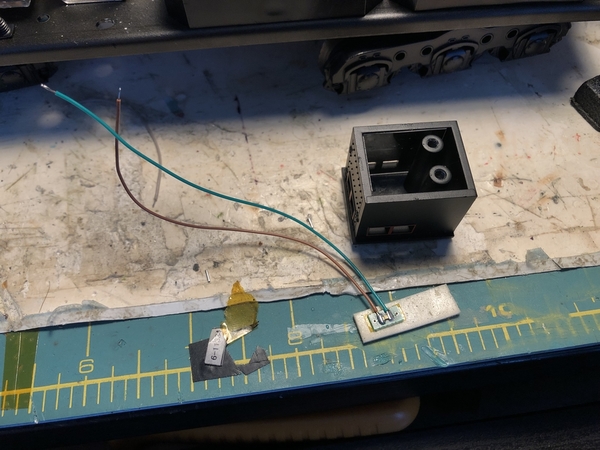

Here is the start of the tear down!