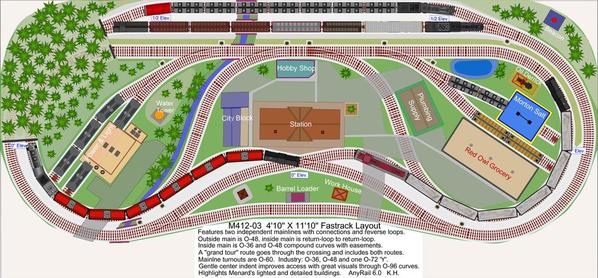

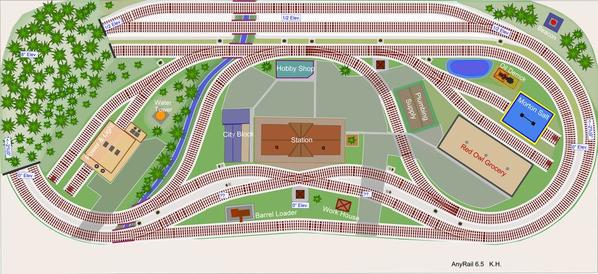

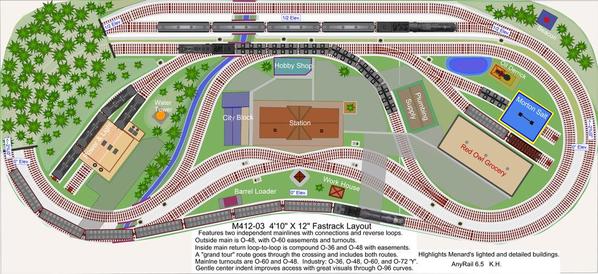

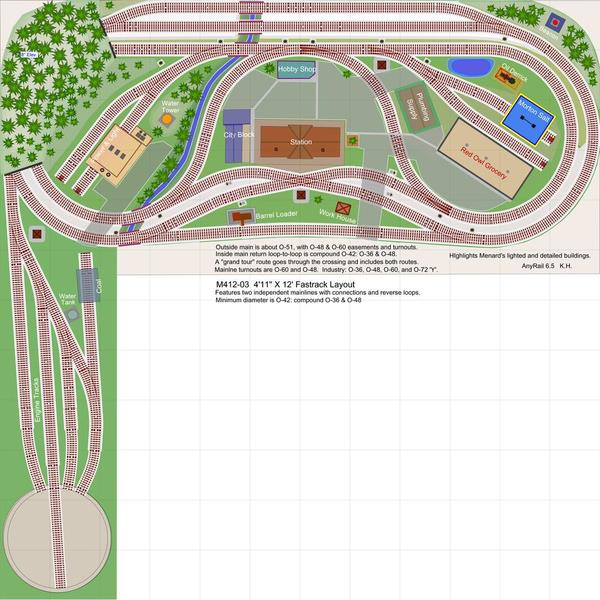

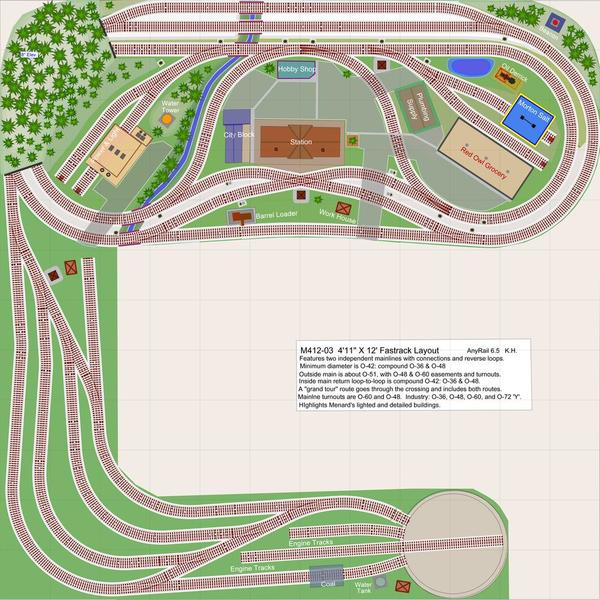

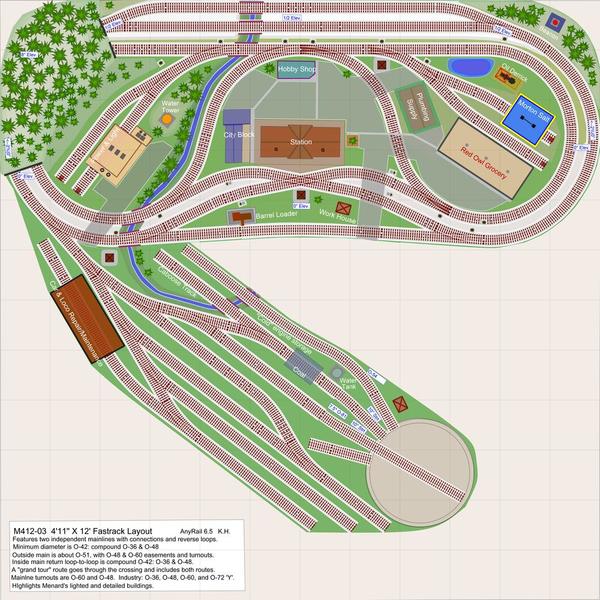

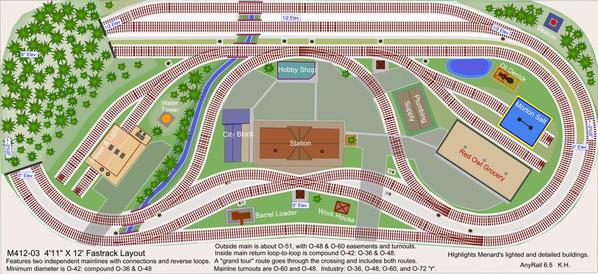

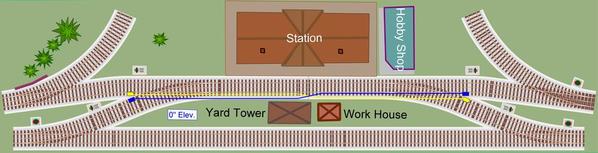

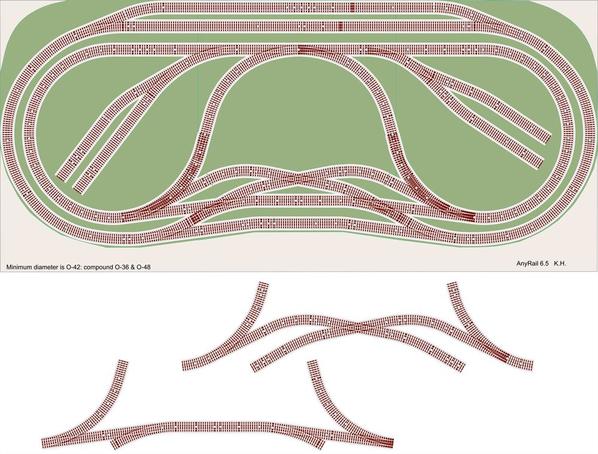

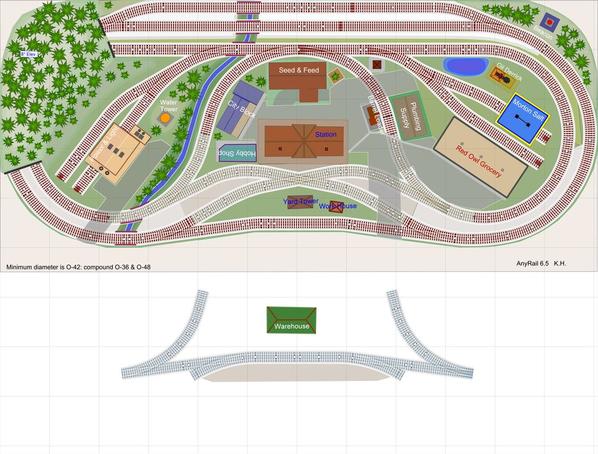

Here is a layout for 3 running trains (with a 4th train in a siding), which is 4'10" by 11'10". Three trains can run at the same time in the same direction if short trains of 6 or 7 cars with engine and caboose. This picture shows three running trains, two steam and one diesel, with a fourth steam train with tank cars in the siding waiting for its turn to swap with one of the other running trains. The crossing in the middle is the thing to watch out for, the trains need to run at the same speed to avoid each other at the crossing.

I have run the layout with TrainPlayer - this layout has many operating options, the most apparent is the two separate mainlines: the outer loop and the inside return-loop to return-loop. If trains run through the crossing route as shown in the picture, they traverse a twice-around route or "Grand Tour".

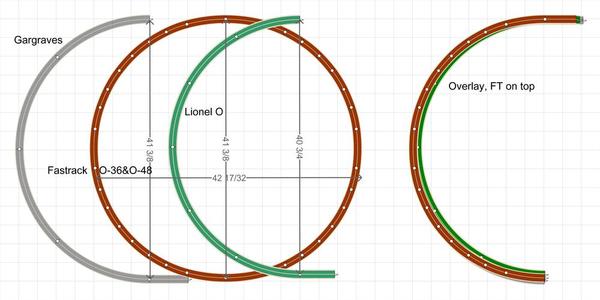

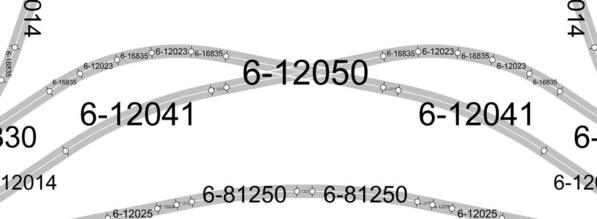

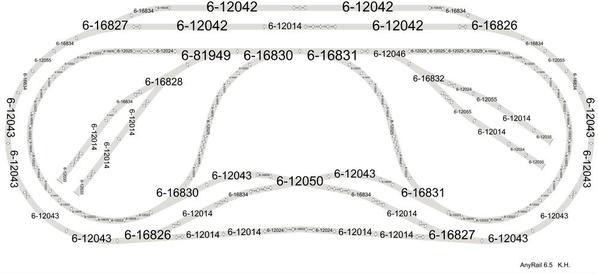

The outer mainline is O-48 minimum with O-60 turnouts. The inside route is compound O36 & O48 of just over O-39 diameter, with O-48 turnouts and easements of O-48 into the loops.

There is a slight 2% grade on the outside main loop which raises the top section of the mainline with the passing siding 1/2" above the rest of the layout. This grade is just to add interest and variety to the layout.

One can also run three trains with the two mainlines, with two trains on the outside main and one train on the inside running the loops. Or two longer trains can run on the two separate mainlines.