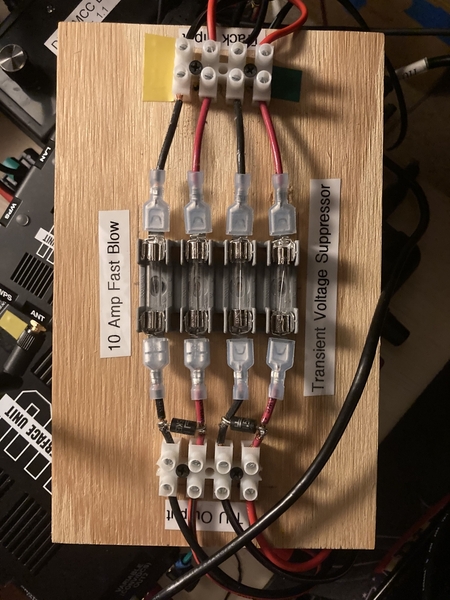

I've had a love-hate relationship with MTH engines, well not the engines, the DCS to be precise. Lionel Legacy locos without exception (well, rarely, very rarely) for me work when I put them on the track. Not so much for MTH engines. I have 9 engines...steamers and diesels. I also control them through the Remote and the App on iPhones and an iPad. Since my first purchase of a second MTH engine I had troubles...two that drove me crazy: "RF out of Range" and "Engine not Found" Engine not found...sheesh, it's right there, on the track..I can see the D***n thing!!! I jsut lived with it. Last week I heard a "crack" when I pushed on the Remote thumbwheel. Trains ran but then problems started. I read about reseating the board, although a direct connect from the Remote to the TIU did solve the issues. I went looking for a thumbwheel/cradle after I opened the Remote and saw the cradle was cracked. No luck, but Mark Boyce graciously came to my rescue and is sending one to me. I also decided to buy another Remote as a backup. Well, I read every thread, scoured Barry's book...etc. Two days ago, I talked to Bruce Benzie about servicing my MTH Bavarian (20-3398-1) because it was a PITA to get any device to find it, and it did, it ran crazily. During my discussion with Bruce...he explained some of the things I should check. (Oh, I was also having infuriating problems getting my J611 (20-3571-1) to be recognized as well). I decided to relook everything associated with my layout relevant to MTH. Wiring was my first look. About a year ago I placed a device Bruce builds to deal with MTH signal issues. He calls it a "Transient Voltage Suppressor" (TVS) . I installed it hoping it would solve my issues. Wrong device for my problems, however, when my engines were recognized I never had a signal issue. I remembered that so I started to trace the power from my ZW-L to the tracks. Oops. I managed to run the output from ZW-L to the Output terminals on the TIU and naturally, track power from the TIU Input terminals to the tracks. Then, I wired the TVS in reverse. It never interfered with my Legacy locos...Anyway...It was a head slapper for me..."In means In...Out means Out" That was The first lesson... Second lesson. I had no idea how important ID numbers assigned to an MTH engine really are. I noticed that my various control devices had different IDs for the same engine...but, hey, they are computers, I just assumed they "knew." They would sort it out. Nah...thus my hair pulling issues. So, after straightening out the wiring, I methodically deleted and re-entered my engines on each device to assure the ID's were the same. Problems resolved. Embarrassment off the charts! So, IN is IN....Out is OUT and Numbers matter. Sorry for the lengthy note, but I thought maybe it would help another poor soul experiencing the same issues...save his/her hair! A shout out to Mark Boyce for his generosity and to Bruce Benzie for his excellent advice.

Replies sorted oldest to newest

Sounds more like operator error than MTH errors. I've been running DCS for nigh onto 20 years and have had few problems. I could relate the problems I had with mechanical E-units back in the middle of the last century.

RJR, that's exactly right...that's the message I believe I tried to convey. Guess not well enough. ![]() ....In fact, comments like yours relating how long they've run MTH engines w/o issues made it clear to me I was doing something wrong...just wasn't sure what. I finally figured it out. Or rather, more like stumbled on the solution.

....In fact, comments like yours relating how long they've run MTH engines w/o issues made it clear to me I was doing something wrong...just wasn't sure what. I finally figured it out. Or rather, more like stumbled on the solution.

![]() We live and learn'.. I've heard plenty of grief from DCS users. A nice easy tutorial on those that have been completely successful with their setups would be appreciated by the masses I'm sure. BTW, Ed, your electrical work is quite impressive'...👌😀

We live and learn'.. I've heard plenty of grief from DCS users. A nice easy tutorial on those that have been completely successful with their setups would be appreciated by the masses I'm sure. BTW, Ed, your electrical work is quite impressive'...👌😀

I have bad news for you. Changing the cradle won't be that easy, as you have to take off the circuit board to get it off. It would be simple if it came out the opposite way, but noooooo. I believe John and David described their methods in the other thread. I gave up on mine until I have a calmer day.![]() By the way, Ed, you can just change an engine's remote address without deleting and adding it back in.

By the way, Ed, you can just change an engine's remote address without deleting and adding it back in.

Ed, Your topic title immediately reminded me of a former telecommunications coworker and O-gauge train enthusiast, Rege. Unfortunatly Rege passed on shortly after his retirement, but he always had a saying at work, "Make sure you have the gozinta and gozouta!" I have thought of Rege from time to time when I can't get the wiring right while building my layout. ![]()

Yes, I believe John H. that it looks like replacing that little chunk of $4 plastic in the remote looks like a job for when I take an extra anxiety pill first! BTW, I wanted to get a second remote for a long time before the announcement that it would be phased out. I bought a new 50-1038 a few weeks ago, but haven't added engines to it yet. If I am not mistaken I saw in Barry's book that you can dump everything from one remote to another, but I haven't dug out the book to check if my memory is correct.

As an aside, Rege used to set up at local Western Pennsylvania train shows. The last time I saw him was at a show, and I could tell he was failing as he talked with me. He was about the age I am now--64. Rege even sold O-gauge trains out of his telephone company van. He was one in a million!! ![]()

@John H posted:I have bad news for you. Changing the cradle won't be that easy, as you have to take off the circuit board to get it off. It would be simple if it came out the opposite way, but noooooo. I believe John and David described their methods in the other thread. I gave up on mine until I have a calmer day.

By the way, Ed, you can just change an engine's remote address without deleting and adding it back in.

John, thanks. I couldn't get the engine to be read, and when I did, it thought it was a different engine. So I decided to methodically delete then add. As you noted, I did change the address once I succeeded in loading it. Problem was also, I had 5 TMCC/Legacy engines loaded into my iPad 1-5 so any new add on a different device started at 1. Soooo, to avoid a potential problem I loaded it as 1, then, as you said, I would simply edit the address to 6, and so forth. Maybe I was anal in that approach, but after my headaches, I knew that would work...fortunately it did!

@Mark Boyce posted:Ed, Your topic title immediately reminded me of a former telecommunications coworker and O-gauge train enthusiast, Rege. Unfortunatly Rege passed on shortly after his retirement, but he always had a saying at work, "Make sure you have the gozinta and gozouta!" I have thought of Rege from time to time when I can't get the wiring right while building my layout.

Yes, I believe John H. that it looks like replacing that little chunk of $4 plastic in the remote looks like a job for when I take an extra anxiety pill first! BTW, I wanted to get a second remote for a long time before the announcement that it would be phased out. I bought a new 50-1038 a few weeks ago, but haven't added engines to it yet. If I am not mistaken I saw in Barry's book that you can dump everything from one remote to another, but I haven't dug out the book to check if my memory is correct.

As an aside, Rege used to set up at local Western Pennsylvania train shows. The last time I saw him was at a show, and I could tell he was failing as he talked with me. He was about the age I am now--64. Rege even sold O-gauge trains out of his telephone company van. He was one in a million!!

Mark, the Rege's of the world are priceless indeed. I love the "Gozinta-Gozouta"....I forgot those simple words of great wisdom...It cost me much hair! You and John are correct. It looks like a real challenge. Fortunately, winter is coming...

@John H posted:I have bad news for you. Changing the cradle won't be that easy, as you have to take off the circuit board to get it off. It would be simple if it came out the opposite way, but noooooo. I believe John and David described their methods in the other thread. I gave up on mine until I have a calmer day.

By the way, Ed, you can just change an engine's remote address without deleting and adding it back in.

John, I took it apart and the cradle snaps onto the chassis I just lifted the rubber membrane that's all the buttons and it pulls right off. I see what you mean about the "circuit board"....sheesh, I'm so glad I have a new Remote.

@Quarter Gauger 48 posted:

We live and learn'.. I've heard plenty of grief from DCS users. A nice easy tutorial on those that have been completely successful with their setups would be appreciated by the masses I'm sure. BTW, Ed, your electrical work is quite impressive'...👌😀

Ted, thanks. I will NOT take a picture of the underneath of my layout. I don't want to give you nightmares!

Mark, your memory is correct. You can dump data from one remote into another, making it a clone. This does not dump the program; that you have to update yourself. Use the MTH 5.0 loader program, to copy contents of old remote onto a computer, then down load that file to the new one.

Mark Do you have any Thumbwheel cradles for sale ? If so I would like to buy two If you do Please let me know the best way to arrange my purchase Thanks FJI

@RJR posted:Mark, your memory is correct. You can dump data from one remote into another, making it a clone. This does not dump the program; that you have to update yourself. Use the MTH 5.0 loader program, to copy contents of old remote onto a computer, then down load that file to the new one.

Thank you RJR!!

Mark, I did read about cloning the Remote in Barry’s book, after I took the remote apart. Timing is everything. ![]()

One should always save the remote's data to a computer. If you ever have to reset a remote, this makes it easy to restore the data without having to punch in everything. Also, if you have multiple remotes, they can all be identical.

@RJR posted:One should always save the remote's data to a computer. If you ever have to reset a remote, this makes it easy to restore the data without having to punch in everything. Also, if you have multiple remotes, they can all be identical.

Yes Sir. I do that regularly with my Legacy equipment because the software, via the WiFi makes it easy. The last time I did that with DCS for me it's a PITA because I cannot do it through WiFi. Sure would be nice if you could. Nevertheless, advice is well taken...I am going to do that today!

@RJR posted:Sounds more like operator error than MTH errors. I've been running DCS for nigh onto 20 years and have had few problems. I could relate the problems I had with mechanical E-units back in the middle of the last century.

Let me get this straight. To recap Ed's issues:

- His Legacy engines have worked right out of the box; MTH locos w/ DCS not so much.

- He's had to directly connect the DCS remote to the TIU.

- The remote's cradle has failed and required replacement.

- He's had to intensely read Barry's Book (3rd party documentation written because for years the vendor refused to even acknowledge the possibility of issues with DCS).

- Had to install a TVS.

- Had to repeatedly add/delete locomotives from multiple remotes.

And your conclusion is that this is more operator error than anything else? Really?

Uh-huh. ![]()

That's not the conclusion or lessons learned I would draw from Ed's experiences.

George

George: REALLY!

Ed, if one is talking about saving the remote's data to a computer, how does wifi get involved?

@RJR posted:George: REALLY!

Ed, if one is talking about saving the remote's data to a computer, how does wifi get involved?

Only with Lionel. They have a software package that has a function that lets you backup the Legacy Base and the Cab-2 via their LCS Wifi module. (Legacy System Utility) It's slick and painless... I do not believe, or at least I have not found, that you can do that in the DCS environment.

@G3750 posted:Let me get this straight. To recap Ed's issues:

- His Legacy engines have worked right out of the box; MTH locos w/ DCS not so much.

- He's had to directly connect the DCS remote to the TIU.

- The remote's cradle has failed and required replacement.

- He's had to intensely read Barry's Book (3rd party documentation written because for years the vendor refused to even acknowledge the possibility of issues with DCS).

- Had to install a TVS.

- Had to repeatedly add/delete locomotives from multiple remotes.

And your conclusion is that this is more operator error than anything else? Really?

Uh-huh.

That's not the conclusion or lessons learned I would draw from Ed's experiences.

George

George, you're close...but I must respectfully correct the record. If I misled, I do apologize. MTH engines did run, out of the box but some did not. Or,jJust not consistently and at times would ignore me even if previously they responded to commands. Too many times I got "Out of RF Range, or Engine not on track" error messages. I installed the TVS in hopes that would solve the problem thinking it was a signal issue, even though my signal was consistently between 5-10 around the layout. There was a time when everything seemed to be OK, mostly. Then the remote thumbwheel failed...I never backed it up. So, I thought I could just start using my new Remote. Errors right from the git-go. I attached it directly to the TIU...no change. I did have different IDs on my iPhone, iPad and Remote for some engines. So, after rerouting the wiring correctly I also deleted then added or edited engine IDs for engines that were recognized so all controlling devices had the same ID number assigned to the same engine roster. In the end, but for the funky original remote, I have to admit...it's me, not MTH. BUT, i hope the new 'software/DCS' team writes code so you can back up and restore data in the TIU and Remote as well as update software for both simply through the WiFi as you can in the LCS, w/o the current kabuki dance with serial to USB cords, etc. Well, I've either helped or confused even more...just like my system before I gave it an enema....

Attachments

Ed, maybe we're not understanding each other. There is nothing in the DCS "base", the TIU, to be backed up. All data is in the remote, if you have a remote. So the computer gets hooked into the TIU, the computer program started, and then just follow the on-screen instructions and the data gets stored in the computer. What would a wifi do? If you are using wifi, the data is in your tablet/phone/whatever, so there is no need to back it onto a computer.

I have two wifi units on mt layout, left over from when I was beta testing the system. Never use them, preferring the remote as easier to operate 4-6 trains on intersecting routes.

RJR...I understand. I like the WiFi DCS interface. I still would prefer the Lionel Legacy Backup approach to schlepping computers around, but, that's me.

Ed,

I just read a few things that aren't right:

First a TVS does nothing for a DCS signal issue. It only works to help protect from shorts.

Second you don't have to delete your engine to change the address. Menu/system/engine setup/ edit engine/edit address and you can change it to what you want.

I would suggest you make a list of your engine addresses to keep from getting duplicates causing trouble.

You are right that Super Glue alone won't fix your cradle in your remote, but I've used Lightning Bond with Lightning Fill years ago on my first remote from 2006 and it still works GREAT! All it is is Super Glue with small glass beads. I just built it up thicker at the break by putting a drop of Supper Glue at the break and then adding the fill and then another drop of Super Glue a couple of times until it is strong enough. Some say you can use baking soda in place of the Lightning Fill, but I still have some Fill left.

I just got some Bondic Repair plastic weld with a LED UV light that might work also, but I haven't used it on anything yet. It looks promising though.

P.S. I also agree with Robert (RJR)

@John H posted:I have bad news for you. Changing the cradle won't be that easy, as you have to take off the circuit board to get it off. It would be simple if it came out the opposite way, but noooooo. I believe John and David described their methods in the other thread. I gave up on mine until I have a calmer day.

By the way, Ed, you can just change an engine's remote address without deleting and adding it back in.

John, I didn't fully appreciate your comment until I started the process to remove and replace the thumbwheel. I could not figure out how to get the circuit board assembly out of the broken cradle...so, I resorted to brute force:

Then I couldn't get the circuit board assembly into the new cradle. I reread your comment...now I understand!

Attachments

I've replaced several cradles, once you do it once, it's no problem. You don't have to destroy the old cradle to get the board out, but you do have to remove the soldered wires.

Ed, try a little crazy glue'.....see if you can put it back together'...

Ed, You used my brother's philosophy, "If it don't fit, force it!" He manhandles everything. I don't ask him to help with anything. Hmmm...smart man!! ![]()

I'm glad you got the idea. I'll be doing it myself one of these days.

I broke a cradle a couple of years ago, so I got a new one from MTH. I replaced the broken one and super glued the old one and put it in parts. I bought a used remote a few months ago from another forum member that worked fine, except that the detent was gone on the thumbwheel, so I replaced it with the glued one. That one is still working after two months, but I ordered one from Midge to be safe. The first one I bought was $15 and $15 for shipping. This one is $20 and $9.75 for shipping. Go figure![]() . I will try to follow John's description and try to unsolder the board and have an extra cradle from the no-detent wheel as a covid project this winter.

. I will try to follow John's description and try to unsolder the board and have an extra cradle from the no-detent wheel as a covid project this winter.

@Quarter Gauger 48 posted:Ed, try a little crazy glue'.....see if you can put it back together'...

Too funny.

@gunrunnerjohn posted:I've replaced several cradles, once you do it once, it's no problem. You don't have to destroy the old cradle to get the board out, but you do have to remove the soldered wires.

Thanks John. I’ll do that tomorrow before the election results start coming in.

@gunrunnerjohn posted:I've replaced several cradles, once you do it once, it's no problem. You don't have to destroy the old cradle to get the board out, but you do have to remove the soldered wires.

John, your tip was the key. What I found was after removing the three wires attached to that little 'circuit' board that sits atop of the thumbwheel mechanism, I also had to remove the board from that mechanism. Then I could get it out put that into the new cradle then reverse the process. Soldered the board back on the mechanism and soldered the three wires back onto the board. Sealed it up and now it works again.... As you said, once you've done it, no problem. However, I hope I never have to do it again!

Once again the folks on this Forum are an invaluable resource...thanks to all that helped me.

Ed, did you have to use a solder wick to be able to reinstall the board? I was able to remove the little board, but there is still solder in the holes.

I'll give you a little tip on removing the solder from the holes. As long as there's nothing delicate on the board, heat the hole and then just "rap" the board on the bench, the solder will clear the hole. Solder wick is frequently a PITA to get solder out of the holes.

I just got this month's dollar's worth from the forum----a tip from Gunrunnerjohn![]()

![]() !

!

Shame on you, John. Any advice from GRJ is worth more than that. Just my 2¢. $1.02 at least

My point was meant to be: Forum for the month, $1. Tip from John, Priceless! ![]()

![]() Amen, Bro

Amen, Bro

Be somewhat careful with the solder sucker. It's possible to suck traces up with the solder, especially if you're not using the correct heat on the iron. ![]()

@gunrunnerjohn posted:Be somewhat careful with the solder sucker. It's possible to suck traces up with the solder, especially if you're not using the correct heat on the iron.

Thanks for the caution. I hadn't realized that.

Excessive heat is the enemy of a PCB. Normally soldering on a PCB is round 500F (260C), that's what soldering temperature most components are rated for.