I'm new in this forum and I wanted to exchange some experience with the experts among you on how to scratch-build metallic train models made of copper, brass, steel, aluminum, etc.

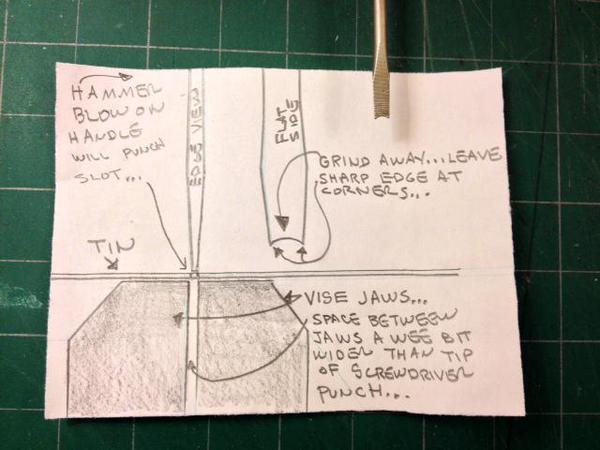

On the attached photos you see the bodyshell and underframe of a hi-nose hood diesel locomotive, which is one of my very first challenging experimental project without bending machine and without any other tooling machinery.