Flanger made from a (shortened) flat car and plastruct scraps

Choo Choo Charlie posted:Keep those great Homemade cars a coming. I have really enjoyed seeing them and knowing other OGR members like making them and saving money.

Here are some of details of my Homemade Centerline Track Cleaning Car, a $3 to $4 version of the brass Centerline, O gauge track cleaning car and it works super.

The price of the Centerline Track Cleaning Cars is quite high listing for $133 plus postage. It is made from brass. The brass Centerline car is a work of art and not required to do a mundane job like cleaning O gauge track. I like the cars design as it has no pads to glue on to replace and no pad motor like the Lionel model.

I worked from a picture of the Centerline track cleaning car and made a body out of wood. The heavy weight of the brass for Centerline is not needed to clean the track as the roller brush rolls freely in the center of the car. The center pit of my wooden version was lined with aluminum flashing and glued it in with epoxy. This area gets wet from the cleaning solution and that would attack the paint and wood of the body.

I used 1 inch diameter mini paint rollers for the cleaning brushes and cut them 1/8 inch of less than the width of the pit (the rollers were the only out of pocket money spent). Pit is 2 7/16 in wide, 2 7/16 in long and 1 5/8 in deep using a part of 1 in diameter paint roller 2 5/16 in long. I used a short piece of ½ inch pipe coupling as weight inside the cleaning brush.

Rubbing alcohol is normally used the cleaning solution. Two or three extra dry cleaning brushes are used after the alcohol saturated cleaning brush and run until the all the wet solution is removed from the track and the dry cleaning brushes show little of the dirty picked up cleaning solution.

The dirty cut off mini paint rollers can be washed in the home washing machine by placing them in a small nylon net bag used for washing small items.

Below is Track Cleaning Car, cleaning roller brush and 1/2 in dia pipe coupling used as weight inside roller when cleaning

Charlie

Great ideal, And good looking.

I seen one made from square steel tubing and small "C" channel iron and welded together. Your 1/2" coupling is from the oil/gas fields and not the standard type find in hardware stores.

Attachments

These are my scratch-built ingot buggies (flatcars).

This one is hauling my scratch-built ingot molds. Hot!

George

Attachments

I made these 3 excursion cars from die cast Lionel post war flat cars.

After reading about Cass then going there just had to have them.

Attachments

Attachments

Several of you train men really have some imagination and building skills. Great jobs, especially the prior four posts. And a super job documenting and photoing your projects.

Your efforts shame my attempts to copy Lionel and others rolling stock.

Keep them coming.

Charlie

Not really Charlie. Not at all. It's a different style of build. I respect "modelers" and "builders" both for what they do to achieve a goal.(inculde yourself in both catagories please). A little better supplies is all you lacked imo. The end result is more than inspiring; it's empowering.

The knowledge behind an engineering degree, doesn't mean they turn screws the right way without a second thought; that is a gift ![]()

![]()

(I'm not making it up, and the guy designed for Caddy, Ford, and Tesla so far; which is fine by keyboard..... but hide the tools from him eh? ![]()

![]()

Choo Choo Charlie posted:Several of you train men really have some imagination and building skills. Great jobs, especially the prior four posts. And a super job documenting and photoing your projects.

Your efforts shame my attempts to copy Lionel and others rolling stock.

Keep them coming.

Charlie

So true I work with several engineers that couldn’t figure out righty tighty lefty loosey. It’s a piece of paper that anyone can get if they pass a test and pay some money. You want to have some fun, start asking about the differences between MET’s and ME’s.... that can be a fun one.... l’ll stop before I get into trouble. It takes all types and everything in this thread is creative and neat. Grace and detail usually come with experience, so the more you do, the better you get for the most part.

When my grandnephews were in their "lego phase", I added a lego baseboard to a few flatcars. They could then customize a train with lego parts to build different types of cars... and whatever!

Open air touring car:

Not a car, but a modified set of Lionelville buildings to make an M&Ms factory and adjoined store:

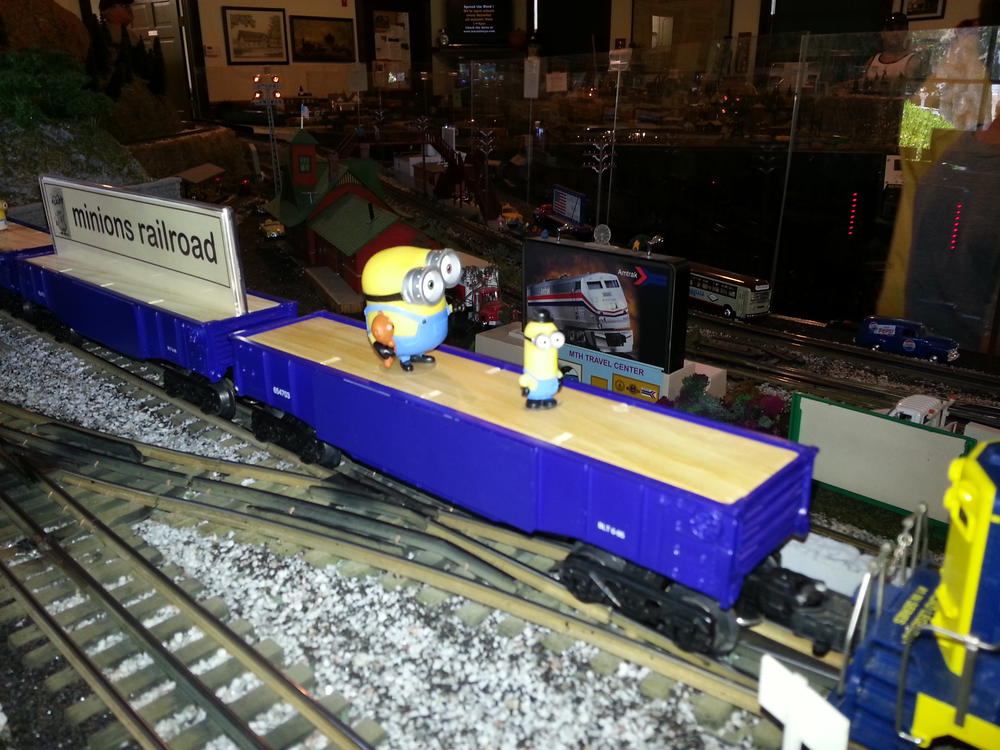

Minion train:

Attachments

I bought a Reynolds Metal covered hopper car without the 12 roof hatch covers. I made a more modern, easy to use center fill cover for the car. The older 12 hatch covers require a special loading bridge with 12 filling spouts and require the opening, closing and applying a security metal seals on each of the 12 hatch covers. The center fill uses 3 or so loading spouts into the center of the car and has a four part center car long cover. The covers overlap each other and require only opening and closing four covers and only one security seal saving time and money.

Charlie

Eddiem, that Lego flatcar idea is brilliant!

Here are my Great Northern woodchip cars. MTH electric trains makes a smooth side woodchip car. They do not make one in the Great Northern Road name. None of these woodchip cars have ribs steel supports on the sides as the ones do in real life. I had to completely redo the car. It is a custom paint job with the correct big sky blue paint I am a member of the Great Northern Railway historical society and have color chips. The decals were also completely custom made. The only thing that is original about this car or the trucks the couplers and the square box belongs to MTH. Everything else is mine.

Attachments

I made a homemade Chicken Dispatch car. A Lionel small stock car was used to make the Chicken Dispatch car. Every other slat was cut out of the side boards and parchment paper was used to Sharpie paint the chickens on. Lights were added to the roof and a pickup made. No chicken poop sweeping man though !

I later bought a Lionel Chicken Dispatch car with the sweeping man but I enjoyed making this car.

Homemade power pick ups were made for all homemade lighted cars from brass shim stock and Lionel plastic sided trucks.

Pickup detail. A piece of tin can was added to improve durability of shim stock.

Charlie