I have the polar express Lionchief set and really like the engine, but would love to be able to get it working with my legacy command cab-2. Is it possible to convert to TMCC, and is that considered a downgrade? I know ERR has modules and you can convert most engines, but haven't found anyone that has converted a Lionchief engine. I am guessing I would also lose the sounds specific to the polar express. Are there any modules to convert to Legacy? Not ready for the price tag on the legacy polar express (6-84685).

Replies sorted oldest to newest

I don't see why you couldn't convert to TMCC, Kits are available from 3rd rail. There is not a kit available to convert to Legacy, these have never been made. You will lose the PE specific sounds that your engine has now and will have to settle for more generic steam sounds sets.

Downgrade... not really, TMCC offers more command options than LionChief and the ability to operate in the good ol' classic conventional mode.

I once upgraded a LionChief diesel to DCS Proto 3 which would be a similar upgrade for you but w/ less wiring. You would need a ERR Cruise Commander and the sound board for medium steam IMO.

As H1000 said, it will be an upgrade in terms of features, but it will not be an easy upgrade. Also space in the tender to actually accomplish the task as well as a tether may need to be fabricated.

Hope this helps!

I have converted several AF Flyer Chief Berkshires to TMCC with 4 chuffs, Electro-couplers and backup light using the original drawbar tether.

http://www.tuveson.com/Berk/burk.html

You can also do chassis swaps with other TMCC berks that lionel produced. I have done that to get a TMCC version of the Berk. G

If you send me an email, I have a nice semi-scale TMCC Berkshire with TMCC that I'll let go for a lot less than the TMCC upgrade price. It even has ERR cruise control, swap the shells and you have upgraded to TMCC. You even end up with a LionChief locomotive that you can sell to recoup a lot of the price of the upgrade.

I seem to remember someone, a Lionel Service Station, converting a Lionel TMCC M1a to Legacy. However the conversion did not include upgrading to Legacy RS.

It's quite possible to "build" a Legacy locomotive nowadays from parts using a TMCC of conventional locomotive as a base. It's expensive and a lot of work.

As others mentioned, the easiest way I can think to do this is to use a TMCC Berk as a donor and swap the shells. This will leave you with a lion chief version of whatever the donor was as well as your TMCC polar express. Of course the sound sets will be swapped, so you'll probably want a donor with generic sounds as opposed to engine specific ones. I'm not up to date on current trends but I picked up a TMCC Lionel Lines engine for under $150 a couple years ago in like new condition, They are not hard to come by.

The next best option is for me to stop being lazy and actually finish the LC/TMCC bridge I'm working on, which allows you to use cab1/1l/2 to control LC/+ engines.

Like I said, I have such a locomotive, and it even has cruise already installed. ![]()

Attachments

Thanks for all the great info. Based on response, I'll be shooting you an email GunRunnerJohn. ![]()

I'm pretty sure ERR has 100 speed steps, while LC+ has only 32. The trade-off is that LC+ uses an optical sensor for feedback, while ERR uses Back-EMF which is not as good. @gunrunnerjohn which would you say gives smoother slow-speed performance and realistic throttle response?

Legacy with 256 speed steps and an optical sensor would be the best of all worlds, but not normally available as an aftermarket "upgrade."

Getting a bit off the topic, but it's still good conversation...

Ted S posted:I'm pretty sure ERR has 100 speed steps, while LC+ has only 32. The trade-off is that LC+ uses an optical sensor for feedback, while ERR uses Back-EMF which is not as good. @gunrunnerjohn which would you say gives smoother slow-speed performance and realistic throttle response?

Legacy with 256 speed steps and an optical sensor would be the best of all worlds, but not normally available as an aftermarket "upgrade."

In all the LC/+ engines I've tested, there are actually only 16 speed steps in each direction. Every engine isn't exactly the same about what the change between steps is, but they seem to be uniform on any given engine with each step being, say, 125% the speed of the previous step. While you don't get as much choice, you do get a good range of useful speeds, especially at the low end.

Prefacing this by saying I'm talking about the actual technology and not necessarily the implementation used in ERR/Legacy/LC+. Back-EMF is "good enough" even at fairly low speeds but does work better at higher speeds. When dealing with can style motors as long as they are turning fast enough not to cog, they are moving at a uniform speed throughout a rotation, back EMF will provide a proper reading of the motor's speed. With older universal motors there is quite a bit of this cogging and not as clear of a electromagnetic path, which is why they are not very friendly to Back EMF reading. As far as the encoders used on LC+/Legacy, these are equally accurate at all speeds, and easier to implement in hardware and software, making them a more cost effective solution. Back EMF is usually relegated to cases where a rotary encoder is just not an option, but it isn't inherently a less accurate method.

Over all I think there would be very little, if any, noticeable difference between say a Legacy engine and a ERR one with cruise other than that The Legacy one would always move at exactly the same speed at a given step where as, I believe, the ERR/TMCC one would stay moving at a given speed, but depending on the voltage the engine is getting when the speed is established it could be a different speed than it was moving the last time that same speed step was set. In this case, LC+ behaves the same as Legacy where the speed is the same regardless of track voltage, assuming there is enough power available for the engine to reach a given speed.

As a side, I think Legacy only offers 200 steps, even though 256 would have mage a lot more sense. Probably done to be friendly to people that like numbers like 10 rather than binary.

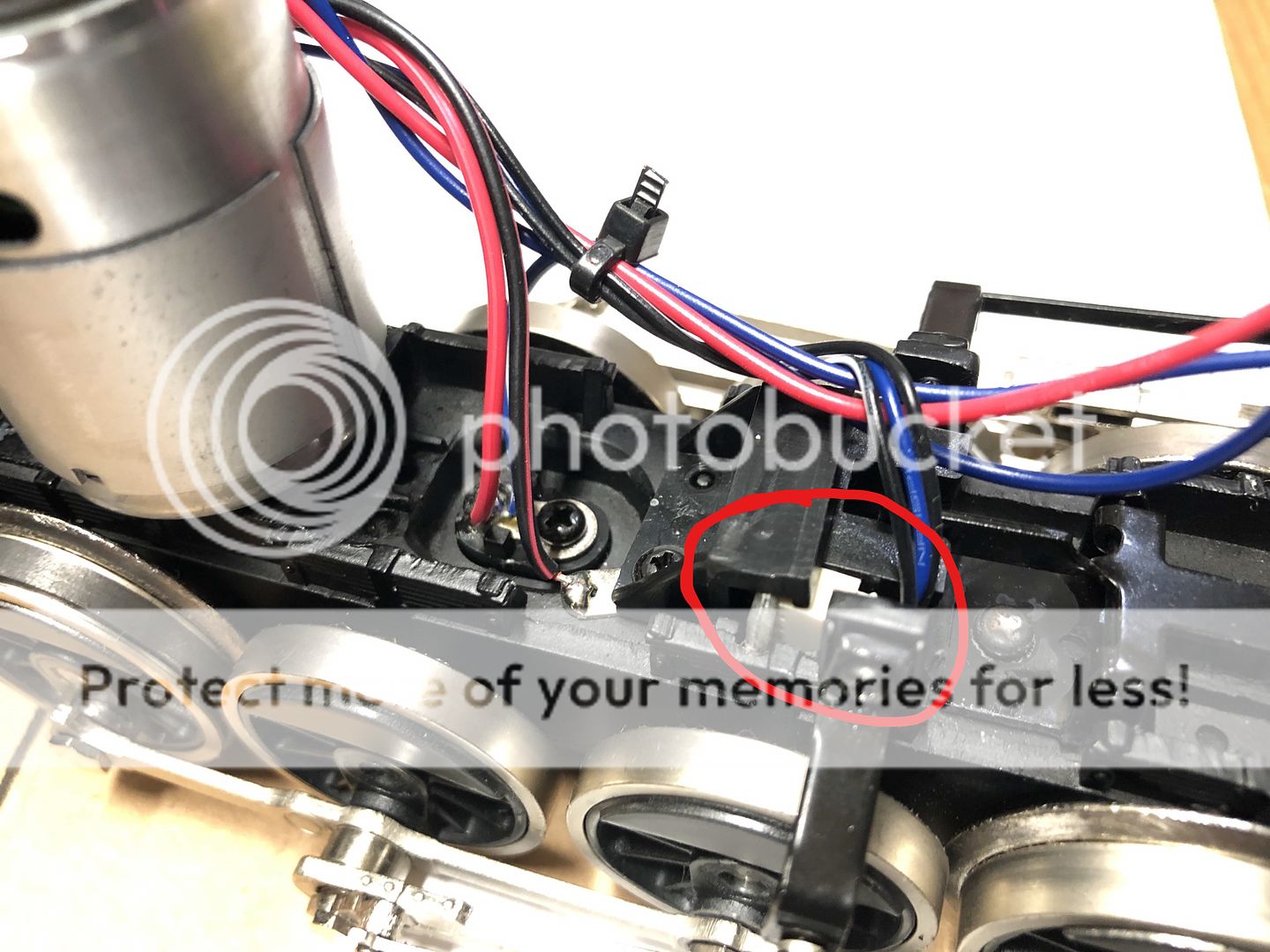

Looking inside the engine, converting over to an ERR board with railsounds looks like it may be fun, so I am now thinking about going this route.

From looking at the wiring, and reading up on some posts, it looks like the lionchief uses an optical sensor with three wire connector for chuff/smoke. Will the signal that this outputs (I am guessing it is just an on/off) be sufficient for what is needed for the ERR chuff in port?

It should be adaptable, though I haven't actually tried it. You will need to figure out what voltage and current limiting the emitter on the optical sensor needs, typically either 3.3 or 5.0 VDC. I don't know what sensor they use.

Of course, they only give you one chuff/rev, so if you want proper sound, you might consider an alternative... ![]()

Going to try to take a closer look at the sensor tonight. Also was looking at your Chuff Generator.