I was given a Lionel 1465 train set. The condition isn't the best, the paint on the locomotive is chipped a little, but a friend who has an N Scale train set soldered a new power cord to the transformer for me. (He and his wife are moving soon, so he doesn't have time to take up with me any longer.) I can get the engine to spark by laying it on it's back and touching live wires to the wheels, but I can't get it to do more than that. Any thoughts on what I can do? I know from research the 1465 isn't too valuable, but since I want to use it in a Xmas village, I don't mind that. Heck, I may even repaint it in my own color scheme. Thanx in advance.

Replies sorted oldest to newest

That should be a 3 position e unit (vs 2 pos. Used in others). It will cycle Fwd, Neutral, Rev,N,F,N,R,N etc .. (N is so you can use track power for some accessories/cars without the train running away while you did it; for blowing whistles before you pull out of a station, etc.)

Gravity; if that e-unit were to fail to work while in neutral, but you really wanted to run it badly till a part came(Christmas?), slowly turning it over in a nosedive, then upright again in a circle would likely cycle it. (I just find that motion best, e unit mounts vary from loco to loco flipping sort of slowly every direction, till a ratchet catches and changes "gears" is the real key)

The wheels should turn by hand, and be clean, center rail roller or pick up shoe clean too. Track too; tops of all 3 rails, and the inside edges of the outer rails. Don't ever clean with steel wool, magnetics will suck up the tiny debris fouling everything up. Small,wire brushes, brass or stainless steel because they aren't magnetic metals, or green/red kitchen scrubbies / Scotchbrite, rags, and q tips and maybe super clean with alcohol (no sparks till dry) or Zippo fluid, or even acetone (nail polish remover) keep these off of paint and any pretty plastics. All flammable, and trains do spark, so let dry.

The electricity, oil traces, and household dust form a black gunk buildup on wheels that can go unnoticed and cause issues.....

Look close, it 's color is often the exact color of a wheel. Dark black/grey and often hard as rock. Alternate to the scotchbright and especially if gunk is thick, you could also scrape and chip at gunk with a screwdriver, knife, etc. to clean or check grey is steel or gunk. Gunk will chip or give black dust, steel will just scratch some and expose brighter silver/grey. Just don't scrape so hard you dig deeply into the metal.... Wheel gunk causes drag, rough rides, bad electrical contact, and wheels climbing right over the rails,as gunk gives grip where there should be metal on metal to slip. Track has the gunk too, but usually not as bad. Clean it sometime, especially the center rail. You will likely need to use less throttle once cleaned.

Since it was worked on, what is the transformer type ? (A number, letter, or description) Not to knock help like your N scale pal, but a Lionel novice may have overlooked some necessary check ups others here might be more aware of. Your transformer is a different animal from an N scale one.

As engines grow old they often like a bit more power too. Some transformers might have trouble running the old train it came with if it wasn't a great match new.

There is some other maintenance for the engine that isn't too hard that you may wish to learn or have a hobby shop service. Like- the next step if the e-unit isn't the issue, would be the motor brushes and armature's circular contact plates that the brushes touch while the motor spins; or... ideally gear teeth want a dab of grease; ..heck maybe even new wheels or axle bearings. I've worn the last bit out both before. With a little care and the occasional parts it will likely out last all of us you know ![]()

YOur friend does n scale which gets power from each outside rail. 3 rail o scale gets powers to one outside rail and center rail. Make sure this is how it is hooked up. If incorrect yu will got sparks., the other way it would spark is like mentioned above. If the rails are dirty. Other scenario where it may spark and short is any short at all. Check that there are no tiny shards or metal touch center pick up roller to any of the wheels, this will also cause a short.

Welcome, If your touching both wires to the wheels your creating a short and will get sparks,in between the wheels there should be 2 rollers 1 wire goes there and and the other to the wheels. If your still getting sparks then the engine needs servicing.

Doug

Wow, thanx for all the responses! I think the red wheel/gear for direction is acting up, I've moved the lever over to either side, to the center, and just off-center. I did get her moving forward on the track a little! The lock-on piece keeps moving, so I'm going to use my jeweler's tools to GENTLY adjust the flanges, to ensure a tighter fit. She is dirty, as are the tracks, so I will be cleaning her soon. I neglected to mention the N-scale my friend has is only one of his set-ups, he has other scales, and even restored a pair of ride-on trains for his grandsons. I will definitely clean everything, gently, and see if that helps. I want a pastel themed winter wonderland for her to travel through, so I'm actually considering painting her to match.

I would hold off till last to tweak the flanges. O gauge three rail is not precise for tracking. There is always side to side play. If it is an older e unit it may not work on its side as someone stated here. I would, if the boiler is off check all the wiring, get rid of old gease and replace with new grease, oil where needed but not too much oil just a drop. Also check the top of the armature for dirt deposits. I gently use a pencil eraser to clean it off. Also I clean out between the top sections of the armature because that area can cause some problems with dirt and grease buildup. Most of the time doing a proper cleanup with the older engines is all you need to get it going again...............Paul

Thanx for the tip, Paul. I'm pretty sure I'll be opening her up soon for cleaning. I have 3-n-One oil, and rifle oil on hand, are those good to use, or should I avoid them? (I work on my vintage sewing machines and my $300 vacuum cleaner, on a regular basis.) Should I avoid using compressed air? Can I use a cloth dipped in kerosene to clean the outside, as done with vintage sewing machines? I'm full of questions!

3 in one oil will attack older cast metal parts. Use Labelle or something that says plastic compatible. Even though you are not lubricating plastic, the oil will not attack the old pot metal.

"Best" would be train specific lubes like Labelle. But use of others have helped my childhood trains run pretty good for over 50 years in my hands.

Roy Boy is seldom if ever wrong, but I haven't had pot metal issues and KNOW 3in1 was used until the late 70s. I just haven't seen or heard of oil caused deteriorations. That said both 3in1 and gun oils likely contain penetration chemicals that may affect some metalurgys, that I know, so I'd be wary to keep it off the porous body, etc.

I'd consider using the gun oil over 3in1, though both are kinda light, beats no oil. Gun oil (I use Stealth often, plastic safe) is great for wiping plate steel for rust protection and cleaning. Gramps compared motor cleaning to cleaning his Garrand. 3in1 is an old formula and will 'dry' to a varnish over time. You will likely be cleaning old traces of it as is. Some modern car 30w ish oil would be better. Lots of folks use Mobil 1 synthetic, platic safe, etc. More from the auto's shelves.. Lucas Red&tacky is a good grease used by many.

Kerosene may lift some paint...? (Test)

Naptha (Zippo fuid) should be milder, and is plastic safe, but still lifts some paints/inks. Test, & stay off lettering.

Careful use of Dawn and water (weak mix) brightens lettering best imo. (Done with Q-tips for care, Dawn goes after oils, ink and paint have oils, even dry) Dry dusting brush only on silver paint. Be wary of modern ink/paint as mfg. of near anything shifts to water based paints and inks.

Once apart, you can clean the body with soap and water, dry well, and quickly. Even steel washes well. The key is drying fully and fast, before corrosion can start..... and oiling steel to prevent rust forming slowly once dry. I've dunked motors and dried with a blow dryer fairly often. (That gun isn't trash if it rains, is it? ![]() ) I dunk my window fans to clean them 3-4 time a season, letting all electricals dry for a day or so in the sun. I also put mother boards in dishwashers, etc. Etc.

) I dunk my window fans to clean them 3-4 time a season, letting all electricals dry for a day or so in the sun. I also put mother boards in dishwashers, etc. Etc.

Water ruins paper; mostly everything else just needs to be dried properly/promtly.

Compressed air is fine, watch the pressure on cloth wire.

Thanx for the tips, I'll try the gun oil first, in a very light application.

CuylerGal posted:Thanx for the tips, I'll try the gun oil first, in a very light application.

Regarding lubricants (and I post this about once a month)....

Your locomotive is a model of a piece of heavy machinery. The stress/strain curves look the same for the real thing (pardon the engineer speak). Best choice in oil is automotive motor oil(10w40 preferred). The best grease is used in automobile power brake assemblies (Sta-Lube Hi Temp Disc Brake bearing grease).

Dawn is an excellent choice for cleaning. And WD40 (not a lubricant) is great for dissolving old grease.

Good luck!

Lou N

Thanx, Lou!

I cleaned some of the track, and Black Betty's wheels, with alcohol. She goes, in reverse only, in a jerky fashion. Some of the tracks are almost completely lacking tin plating, I think on the ones where there is more tin, she goes better.

BTW, thanx for the welcomes and the help!

If the rails are rusted or more heavily damaged where the locomotive jerks, I would consider buying new track as a replacement. I had this problem with some O-36 with my newer locomotives where it was so worn down, I had to buy new track. I would go with either Lionel 027 tube track, Fastrack, or MTH realtrax. If you really want to go the extra step of track, get Atlas O 3 Rail track or Gargraves. Even if they are more expensive then fast track or tube track, they will last longer and look like real track. As for the lock-on, if this is the original, replace it if you stay with tube track. I would not get any track larger than 036 track if you replace it for this set as it is a 2-4-2 compared to say a 6-8-6. I would open the unit up and check for any loose wires, or even take it to a local hobby shop for an inspection.

The thumbnails cannot always be seen by Android users. The viewer can take forever to load pics some days, or close the page fully when you exit it, (loosing any text you may have started, etc.)

Basically, trying to use them is unpredictable for me. BUT as you load pictures, just before you hit finish, a small check box appears "insert full size". Check that and it will appear full sized wherever you last had the cursor. If you forget, there is an insert tool in blue at the bottom of each photos thumbnail box(here you can choose small, medium, or insert full size)

I.e. I'll answer again later but just lost a few paragraphs (twice ![]()

![]()

![]()

![]()

![]()

![]()

![]() ) . I need a frustration break

) . I need a frustration break ![]()

....and still have not seen the photos, lol ![]()

Could you repost or edit? (under "take action")

Google/Android predictive text and spell check is responsible for most of the mistakes you may see. Shutting it off does no good. Google products do what they want to do, not what you ask them too... My fourth. ( Only used here because they are so cheap it is hard to say no)

Ok, hope you weren't waiting. I was keeping an eye on a domestic hostage situation 15 houses away... Happy ending with a straight jacket, no shots, but wow!

Anyhow, just reverse only, that points at the e unit "fingers" and or drum contacts. (Assuming you know the unit cycles, turning the red drum) (color of drum isn't too important, except some colors had bad production runs) Overheating and age can cause the "fingers" to "cuyl" like brass in a thermostat. Some will even work then stop as the motor warms up too. As long as the eunit coil draws the rod into it it should be able to be rebuilt. There are two boards with finger like contacts and a new drum with these kits. It will require some soldering (not hard, guidance is here, a great skill to learn. Irons can be had pretty cheap, a useful tool I bet might be useful on the electric "Singers" as well). The e unit frame is not ment to be disassembled. You have to spread the frame for removal and installation of the boards and drum.

There is a prying tool to ease doing this(a juggling act). The cheaper tool is a small but special shaped pry bar, others use a screw to open it. It can be done without the tools as well. Sometimes a vice,is needed if overspred. The,tools help prevent that some.

Track: new track is great. The trains run better, smoother. The electricity flows better. It looks great. There is a tone difference with the plastic roadbed & ties on modern tracks compared to tubular like you have now. Many a thread on this....and opinions on what is best. Metal may scratch floors more, but both will. Putting cloth/carpet under it will help tons... helps noise too. (Shag carpet fibers can be a pain, wrapping on axles, etc. causing wear and other issues)

If your not super brand loyal, Menards track is nice. Early runs had some issues, so buy new imo. Order online or at the store (not stocked there) But it was under $50, 3 days to my door, for a 36" circle, 8pc, about 2 years ago. Lock ons are cheap. You can solder wire to Track as well. Full O; it is strong enough to step on without an instant crush. (Fyi, 0-27 is a lighter steel, shorter height, smaller curves, smaller tube& pins, not all trains can run on it because of the tighter turns. Mixing the two takes some modifications or special pins. 0-27 may bend easy if you step on it; big difference in how strong they are. Tubular track is basically universal too. Menards works with Lionel turnout tracks etc... Plastic track requires special adaptor tracks to mix brands (can mix with tubular too though)

Before you disassemble the E-unit (relay with the red drum), you might want to try cleaning the drum carefully with a QTip wet with pure mineral spirits. You must be careful not to disturb those little metal contact fingers, which are fragile.

let the drum stay wet and rotate it. This will help clean the fingers themselves.

The use a dry QTip to absorb the excess.

Sometimes this process will resolve the issue, other times not.

Once clean, an e-unit should not be lubricated.

I looked up your set, 1465. The engine should be a 2034.

Here is a link to the Lionel factory service manual pages for your engine:

2034 Service

As for the directional lever, what are the positions? If we have forward, neutral, reverse, would it be left - forward, center - neutral, right - reverse? Whether or not the lever is all the way over to left or right, it goes in reverse only.

The lever is a simple on-off switch for the reversing unit. The direction is controlled by the position of the drum. The drum will not be rotated properly unless the motor is in the upright position. So, if you have the motor with the wheels up, or on its side, the direction will not change.

Plus the e-unit must be switched on.

Paul2's comment on flanges, I just noticed he is referring to WHEEL flanges (the most common use of the term flanges here). Getting the lock-on flanges to grip tighter is advantageous and shouldn't affect tracking at all. Pressure of electrical contacts is directly related to a connections quality. More pressure will produce a connection capible of flowing more power; it reduces any connection resistance (that is scientific fact most folks are unaware of )

(Adjusting wheels on the axles for proper width between the flanges is "gauging the wheels". When you wrote of tightening flanges, if it was on wheels, that could have caused issues binding in the curves. (Adjusting is sometimes needed, but not really very often on a wheel set that isn't really spinning yet; no way to know yet ![]() )

)

Thank you for enlarging the pics. Navigation got so bad last night I loaded three new browsers to try out. After I posted it wouldn't even refresh, I thought that post failed too (which would have been a fourth fail of a long post...Aaarg!) The posts will get shorter as we learn how much you already know.

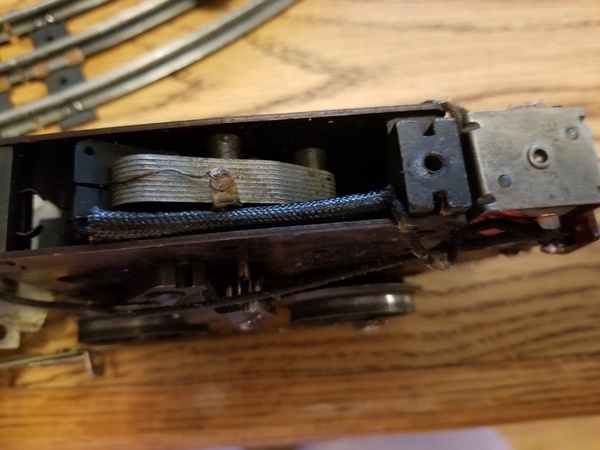

I'd clean the eunit as CW suggests. The motor looks good overall, 'cept the pilot wheels (small front) have a gunk ridge on the treads to be cleaned ![]()

(Fyi, Photos are great for seeing stuff the naked eye misses. Every tiny flaw seems to be highlighted. Drives modelers nuts ![]() )

)

What I noticed is the plunger is up in the coil. It should not be there if the motor unit is upright (it looks as if it is.) My guess is the plunger is stuck in the coil tube. The lever on bottom is to turn on or off the reversing mechanism. When on (you will hear a soft buzzing) the engine will cycle forward-neutral-reverse-neutral-forward. If the switch is off, the last cycle it was in it will stay that way. There is no center position on the switch lever, either left or right. You might put the motor assembly on the track and observe if the plunger and pawl are dropping down and grabbing the cog on the drum and shifting it to it's next position. Where it is at now in the picture, the unit is on.

C W, thanx so much! I'm going to keep going at this, but if I get in over my head, there is a repair shop an hour away from me. (I wish my dad were here. He could get old clocks running, this would so be up his alley!)

I have confidence you've inherited that "fix it" gene ![]()