Personal experience and feedback from message boards demonstrates that successful operation of the new 2021 version of the Lionel Acela requires a set of skills beyond that of the normal plug-and-play nature of train sets.

In other words, this train set has some issues and challenges!

Many of the problems relate to derailments, nosecones that don’t hold in place, motor failures, engine electrical shorts and decoupling of cars due to loose screws.

Here is a compilation of ideas and suggestions to improve your odds of success trying to operate this train set on O-72 and larger curves. This list will, no doubt, change and evolve in time as more Acela owners report their experiences, issues and solutions. Corrections and comments are welcomed.

Perform Initial Inspection Visually:

Engine:

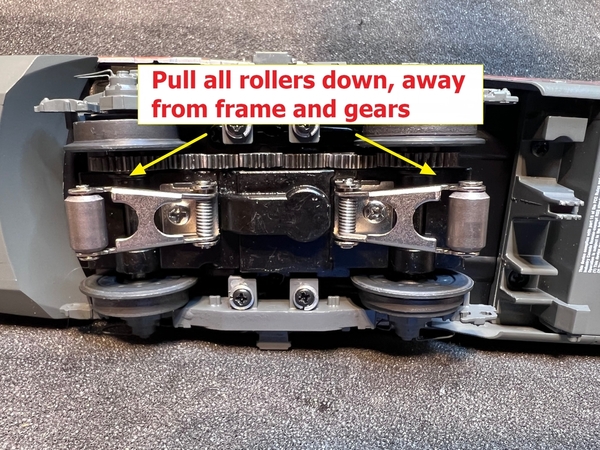

- Rollers: Turn engine over and check that rollers are not stuck into frame. (Problem noted by several.) This will cause a direct short across the rails. Pull rollers away from frame to hang down.

- Particle Removal: Remove top hatch by applying pressure to the side shown in the photo and lift. Turn engine upside down and shake to remove any foreign objects from inside engine. Leave hatch off for now.

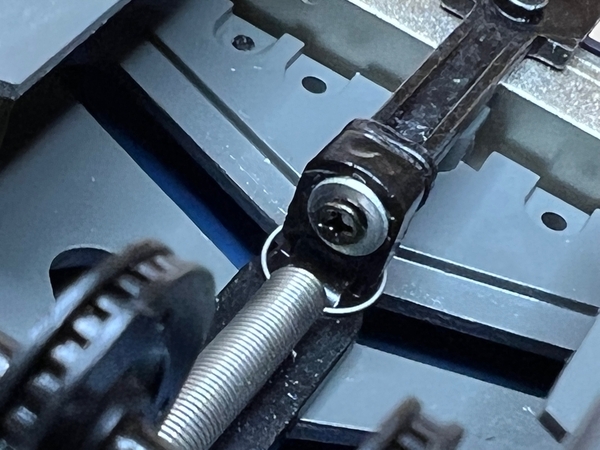

- Loose Coupling Screws: Inspect screws in coupler to check for tightness; (common problem). A loose screw will eventually lead to a de-coupling. A small drop of super glue can be applied to prevent the screw from working loose. (Idea from @Lionelzwl2012)

- Loose Nose: Check nosecone to see if loose (common problem): Replace when new nose part becomes available. If loose, either return to Lionel for repair, wait for a new nosecone to become available in Lionel Parts site, or use non-permanent bonding agent. For example, “Le Glue”—used for temporary LEGO bonding—will not permanently damage the plastic while you wait for a new nose.

Passenger Cars

- Coupler Screws: As mentioned above, inspect coupler screws for tightness. (Common problem) Tighten screws as needed; light touch of Loctite or superglue on screw head.

- Coupler Oiling: A tiny drop of Labelle's 108 light oil can be added to plastic parts that move. This includes the side skirts that move outward when going around 072 curves and areas where the mechanism rubs against the frame body. Wipe off excess oil. This ensures that the couplers movement is smooth and will travel side-to-side without binding. The oiling will help the cars track through curves. (Idea from @Lionelzwl2012)

- Wheelset rotation: Inspect height of car above wheels (separation of wheelset to frame) to ensure wheels will freely rotate in either direction. If wheel set doesn’t rotate freely, return car to Lionel for repair

Above is good separation

Above is defective separation. Car will derail

- Sticky Pin and Loop Couplers; If you have difficulty uncoupling cars, it may be helpful to widen the loop using a miniature flat file.

Layout Integrity:

Scenery

- 21 ½” long passenger cars that tilt require that scenery must be moved back from inside curves to allow clearance. For example, O-72 curves require tall objects to be more than 1 ¾” away from inside curve.

- Take single passenger car and move it by hand, where possible, throughout the layout to ensure side of car is not brushing against scenery.

Track (preliminary test)

- The Acela set requires that the trackage must be laid out perfectly (literally!) with no discontinuities (smooth track transitions and consistent O-72+ diameters) and no dips; i.e., no kinks, bumps, dips and ≥ O-72 diameter curves

- OPTIONAL: As an initial test, put all passenger cars on track and try to pull them throughout layout with a substantial engine. (Anecdotal experiences infer that the Acela motors and gearing may be a bit more unforgiving than other types of engines.) Unless a fast-acting breaker is employed, the use of the Acela engines is not initially suggested because derailment of cars can cause significant drag (i.e.; undue stress) on them and can lead to a motor failure. The idea here is to check out the trackage as thoroughly as possible before the Acela engines are actually used. This is an example of a way to couple the Amtrak cars to a more substantial engine using a coil wire:

- Derailment is a common problem. Derailment fixes are described later in this message

- Thoroughly clean track. During the initial run of the train, described below, this will help ensure both Acela engines will receive virtually identical voltage levels at the same instance when operating.

Engine Set-up

Programming

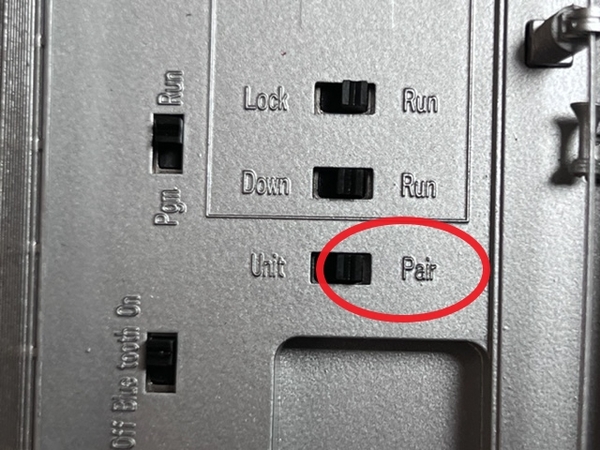

- With top hatch cover off, it is critical to set engine as a pair, not a unit, using the same engine ID for both engines. Lionel Support now recommends this approach even though it differs from the manual included in the set.

- Put both engines on track and apply power. Put both engines in “Pgm” position and enter and engine number on the CAB2 and press “SET”. Return engines to “Run”.

- You’ll run the engines as a pair, not as a LASHUP. You will not be using the TR button. (IMPORTANT!)

- If you have a Lionel LCS Sensor Track, run engine #2021 over sensor track to populate CAB2.

- If you don’t have the sensor track, here are the manual settings:

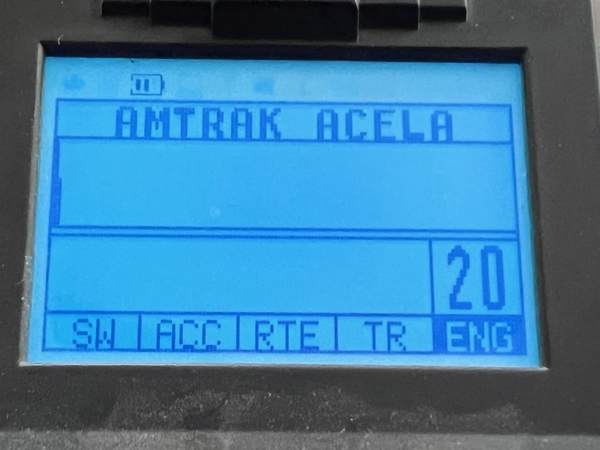

Initial Main Display: AMTRAK ACELA (Engine ID is your choice)

Engine INFO menu:

Custom: ASSIGN NAME (Your choice)

Type: ELC (select “Electric”, not “Acela”)

Control: LEG

Sound: LRS

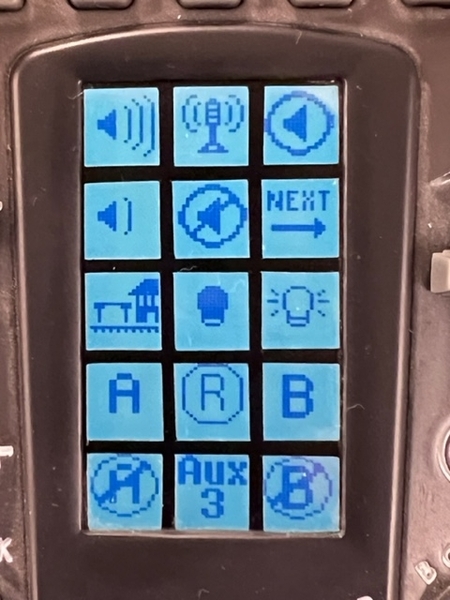

The CAB2 screen should look like this:

Operation

Initial Testing

- With both engines on track (no passenger cars), but separated by a foot or so, run engines forward and reverse throughout the layout to see if they maintain the same distance apart.

- Check engine and bell.

- Check operation of the pantographs. After test, lock them in down position and turn them off for now so they will not be an issue in future test runs.

- Check Bluetooth operation from a smartphone or iPad using the Lionel LionChief App. This app contains all the basic operating functions and is easy to setup and use. The screens will look like this:

- iCab: The set can be controlled also using the iCab smartphone app via a WiFi connection but this approach requires the use of the Lionel LCS WiFi device which is very difficult to set up using modern home routers. Judging by the number of iCab reviews in the Apple Store, the iCab is not very popular. The iCab app, when properly functioning, provides similar capability to that of the CAB2. It is anticipated that the forthcoming Lionel CAB3 base and app will make smartphone operation more capable and easier than the current iCab app.

Initial Operational Run

- Try to use fast-acting circuit breaker so engines will immediately halt on a derailment. The breaker built into the Lionel 180W PowerHouse is very fast-acting. For other power sources, a AIRPAX/SENSATA PP11-0-7.50A-OC-V will instantly break power in a derailment short. Just make sure your power source has some sort of breaker or be prepared to quickly kill power.

- Attach all cars to the engines; double-check that all wheels are set properly on track.

- Here is a prototypical configuration with 2021 as the lead engine:

- Power (2021)

- Business

- Business

- Bistro

- Business

- Business Quiet

- First Class

- Power (2024)

- Slowly run cars throughout layout; slow is best if fast-acting breaker is not available.

- Derailment remedies. If derailment occurs:

-- Immediately shut off power if breaker has not already tripped.

-- Observe if derailment is occurring on the same spot on the layout. If so:

-- Check if track is level across from one outer-rail to the other outer-rail. If not use shims to correct; OK if track is banked towards inside curve.

-- Check if track is going through a sudden dip or bump, especially on curves,

-- Check if derailment is occurring at a kink or un-smooth transition between rails.

-- Consider replacing problem track sections (like with pre-formed track) to ensure O-72 and greater curves at all points and to ensure smooth transition between tracks. If track is not consistently O-72 diameter, the cars will derail.

-- Fix uneven base or dips so track is level; bank track, if necessary, on problem curves. Here is an example of a track dip being corrected and also banked in a tunnel where the homasote base was uneven:

-- Tight S-curves, even though of proper radius/diameter and proper transition, may be a problem for the passenger cars to navigate.

-- If derailment is always occurring on one car, remove car and run consist again. If all is well, then inspect the wheel set on derailed car. Check that it rotates freely. If not, send car back to Lionel for repair.

Engine Roller Lockup -- As mentioned above, when the pickup rollers lock up into the frame, the engine will produce a short across the track. Sometimes the lockup may occur as the engine passes over a crossover or switch. A cure is to glue a 1/8" thick piece of Styrofoam under the roller.

Acela Engine Blinking Cab Light and Stalling Problem – This Acela set appears to be more sensitive to the type of transformer used. Specifically, the post war (PW) ZW at full throttle did not work reliably. Engines routinely would go into a blinking-cab-light motor stall on startup with the PW ZW. Same problem has been noted if the controller box is used with the MTH Z1000. Transformers reported to work well are the ZW-L and Z4000, and power bricks like the Lionel 180-watt PowerHouse and MTH Z1000 (less controller). If problems continue, try to minimize wire resistance between transformer and track by using shorter wire runs or larger diameter wires. To restart the stalled engine, follow the reset procedure at the end of this message.

Adding Bistro Car (from expansion pack):

- Assign unique ID to Bistro Car

- The Lionel LCS Sensor Track can be used to populate the CAB2

- Manual setup is as follows:

Lionel Assigned Name: “The Acela Bistro Car”

Type: PAS

Control: LEG

Sound: LRS

- The screen will appear as:

- Do not attempt to add as a LASHUP nor assign a TR number.

- Do not attempt to use TRAINLINK.

- During operation, go to ENG and type in ID number. Rotate speed control to bring up sound options. The Bistro Car sounds will then be controllable,

- To switch control between Acela Engines and Bistro Car, simply double-click the ENG button.

- BTW, the Bistro car’s speaker is exposed in the interior. This is how the car was manufactured.

- Unfortunately the Bistro Car does not call out the individual station stops along the Northeast Corridor

Bistro Switch Settings -- The factory legend pasted on the Acela Bistro Car trap door is confusing. Here are the correct color-coded markings for the Bistro Car:

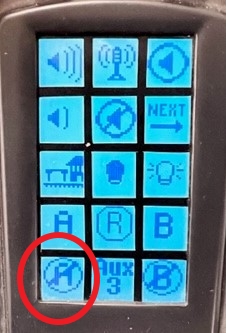

Eliminating Bistro Car Annoying Sounds -- Another issue with the Bistro Car is that the default factory sound emanating from the moving car is an annoying rhythmic knocking sound. To eliminate the sound, simply press the lower left button on the CAB2 keypad.

=====================================================================

Engine Reset Procedures – If the engines fail to respond to commands (e.g., cab light blinking because its software “thinks” there is a motor binding issue), try to reset the engines. Here are two reset options:

Reset option #1 when continuous one-blink error code occurs: (Idea thanks to @MineRun) This “unbinds” the motors to the satisfaction of the engine software

- Hit reset (“R” with octagon around it) to turn off the blinking cab light,

- Press down the 'boost/brake' wheel to reverse the direction,

- Turn the speed wheel clockwise to back the engine up ever so slightly

- Reverse direction again

- Turn speed wheel again to move forward

Reset option #2 for general reset:

- With power on track, press the “R” with the octagon around it. The engine should respond with a short whistle.

- Turn off power to track

- Turn off command base power to stop TMCC/Legacy radio frequency from reaching the track

- Wait about 30 seconds.

- Restore command base power

- Restore track power.

- Turn speed wheel to move forward