Never trust a meter with a low battery. I've had some stupid reations out of a few trying to avoid a trip for one. Reads fine one second, off value the next.

I LOVE chip sockets for repair. If it died once, it may die again. No soldering in the later repairs, just pop, plunk, press then go eat lunch. Always money well spent imo.

If you had a 4a diode handy, it should work, but is overkill. I have a few 6a running with single LEDs because they were here and free, salvaged from "something or other". The 4000s are plenty though, and twice as common. I just didn't want to trash the boards that had them yet.

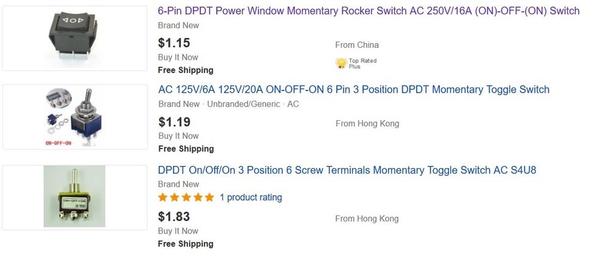

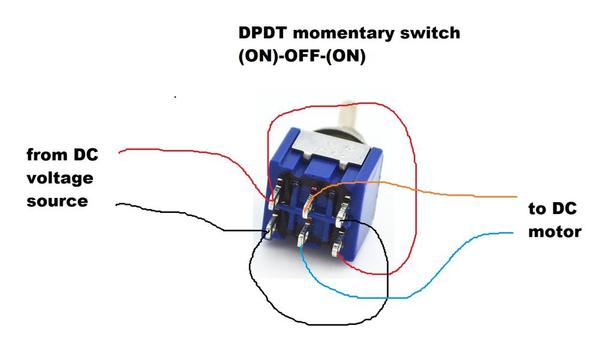

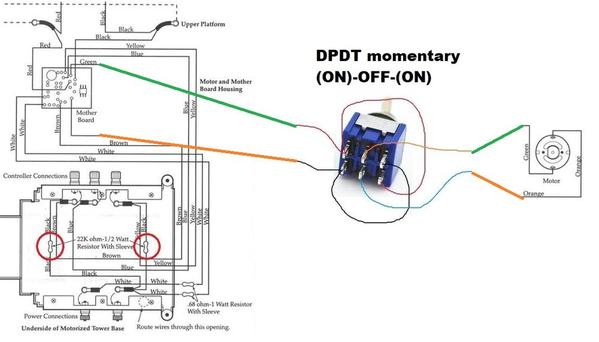

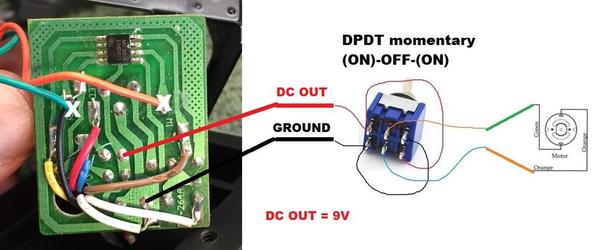

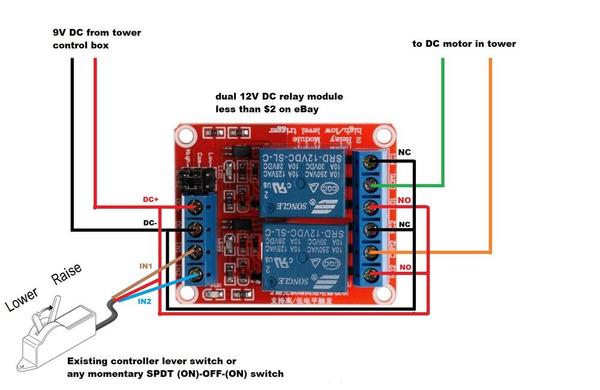

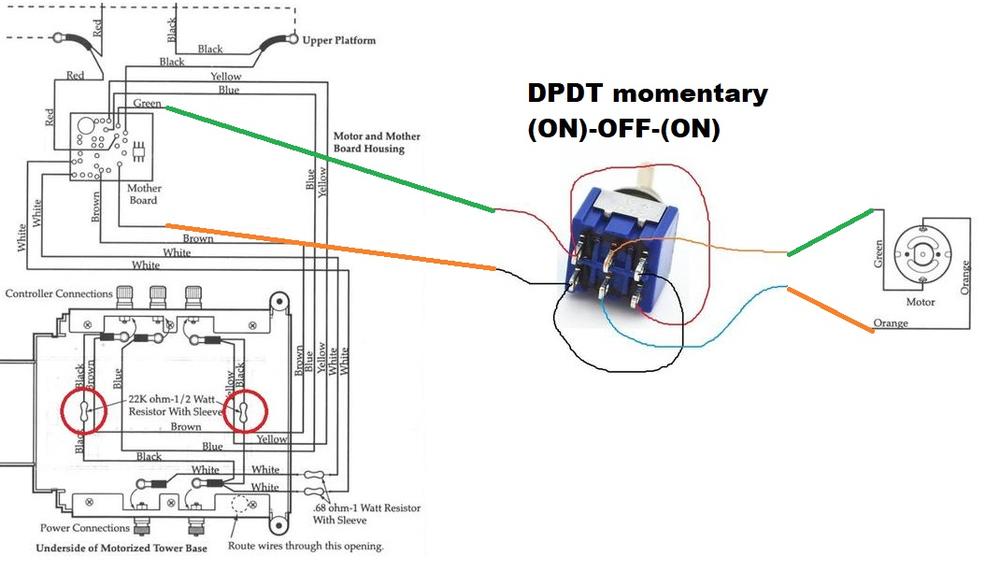

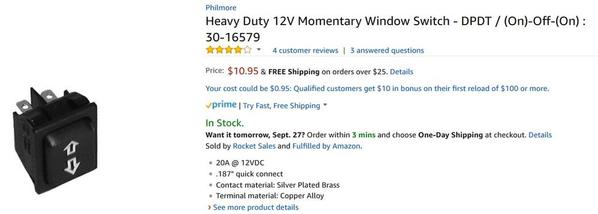

They won't be cheap, normally a high amp rating, but many machine controls use the sprung, temp on/off/temp on, dpdt for jogging purposes. Grainger would be my first stop, but after that, Im stuck......

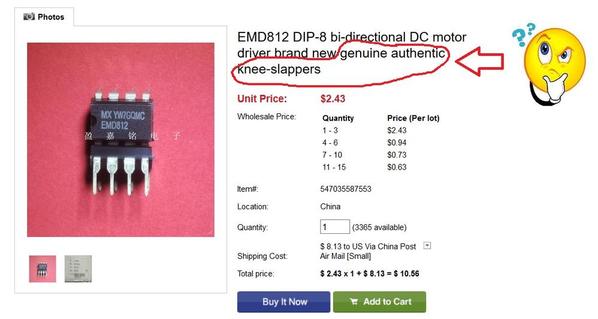

( Thank you Mike, but) .... I realized about a year ago after noticing a lot of my favorite chips were " obsolete", that I was "out of date" and unable to really keep up with helping in depth anymore. Too many new parts, and not enough reference compared to what I had fast access to at one time. I'm still going to stick my nose in and help till cavalry arrives, but I concede to those deeper in the game today for the same reason as you might. I have no design from scratch experience. I repaired, and focused on changes of specific areas of weak design in a few fields. There are just more folks posting on OGRF now that know more modern parts available than I do, or will ever know about from here on in, than there was a few years back.

FYI everyone, just know its not apathy that keeps me quietly lurking this section. It's all those mystery chip numbers and poor reference ability. I never ran into that before train electronics, except in some automotive applications. Mostly, once you asked, the manufacturer came through with anything you asked for. I ran up against this for the first time ever with Lionels TMCC intro decades ago and commited myself to used items only by them from there on in. (commited? E.g. I've only bought about 6 Whoppers since "the Burger Wars", and only because I have low blood sugar. It's my fav., but...well I have my reasons)

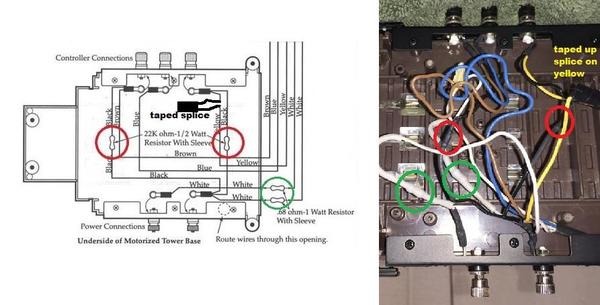

Besides, I do prefer PW. This repair is one example of why. IMO, the whole thing was electronic design ovekill. A couple of common transistors and/or relays were avoided in favor of an unproven or weak chip. I feel like it is an unwinnable battle for me with "proprietary secrecy" and not at least having a board around. I miss when I could contact a mfg, get info fast, make changes, send a fax, possibly see a revision done to save others the hassle..

....and still go to lunch on time