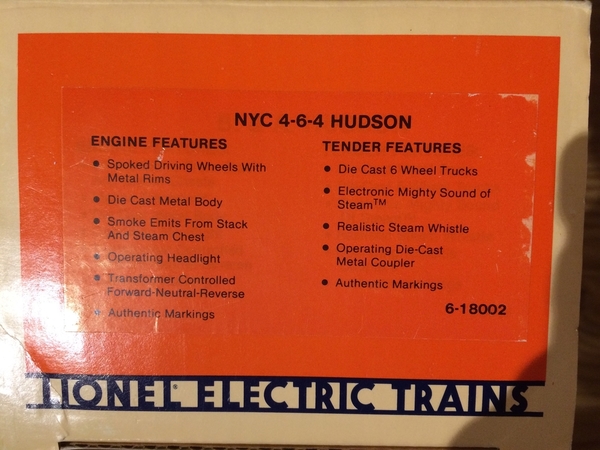

I'm looking at the Lionel 6-18002 Gray NYC Central Hudson, road number 785. I think it looks really nice has the dreaded Mighty Sound of Steam and will supposedly run on 0-31 curves but likes 0-72 better. Does anyone have one of these? What do you think of it and will it run well on 0-31 curves? Any input would be appreciated.

Replies sorted oldest to newest

I have one and it runs on 036 fine so maybe 031 as well? It doesn’t have Mighty Sound of Steam. Whistle is all.

It’ll do 0-31 just fine.

And yes, it does have Sound-of-Steam and a whistle.

TRW

It's pretty much a copy of Lionel's 773 and that was designed for 031 so the 785 will do just fine.

Jim 1939 posted:It's pretty much a copy of Lionel's 773 and that was designed for 031 so the 785 will do just fine.

But it will look really odd.

Coach;

Mine hasn’t been on the rails in many years (it is a beautiful shelf queen) - I am strictly Legacy these days, and I really don’t remember how it ran. That being said, it is very nicely detailed for it’s day. It does have the infamous Mighty Sound of Steam (per Mitch M., be sure and check the foam under the circuit board in the tender before running it).

Attachments

Apples55 posted:It does have the infamous Mighty Sound of Steam (per Mitch M., be sure and check the foam under the circuit board in the tender before running it).

If I remember correctly, the tender for the 18002 is among the first to have its Sound-of-Steam board held in place by an injection-molded bracket. There shouldn't be any foam pads to worry about on these.

TRW

I have this engine and still run it periodically. Unfortunately, my 18002 is not much of a runner or puller. Of all the Lionel engines I have, and I have a bunch, this one sounds the worst by far-an oversized coffee grinder comes to mind. It does have the mighty sound of steam and as loud as that is it does not quite drown out the sound of the motor. I have tried everything to quiet the motor on this thing but nothing has worked. However, it does look good on a shelf so I plan on keeping it.![]()

Also, I run mine on 072 track and it looks real good on the wider radius curves.

PaperTRW posted:Apples55 posted:It does have the infamous Mighty Sound of Steam (per Mitch M., be sure and check the foam under the circuit board in the tender before running it).If I remember correctly, the tender for the 18002 is among the first to have its Sound-of-Steam board held in place by an injection-molded bracket. There shouldn't be any foam pads to worry about on these.

TRW

You are correct, TRW. I looked at the Lionel Service Supplement (Supp. 10, pg.4-1) and you are correct - the board is held by a plastic bracket.

Timko makes DC motor conversions for these, and then I can give you a dynamite command upgrade with fan driven smoke, great sounds, etc. ![]()

Have one,love it....I run it on O36...if the price is right....buy it.....

I'm torn between the 18002 and a Williams Brass 4000 Hudson. I think the 18002 is better looking but not sure which is the better runner. I've got 0-27 track with a 42" outer loop so I believe they'll both run on the outer loop and any 42" turnouts but I don't believe either will negotiate my 0-27 turns or my yard with the 0-27 switches.

out of the box the Williams will run better than the Lionel....the Williams is already can motor equipped, however the Williams, even though that model is brass, is not super detailed.....but, send it to GRJ for smoke an sound upgrades, and you'll have a whopper of a Williams Hudson by then!...……………….Pat

Joe,

Some run better than others. Just give it a good lube before running. All the Hudsons seem to have no problem with 031.

In action at about 1:30 in this video of mine:

Jim

I love the gray Hudson. In its time it was great engine. If you like command control do as GRJ suggests and convert to can motor and ERR cruise. It’ll run with the best of them. I really wish Lionel would do this style of Hudson with Legacy at an affordable price. No need for all the super detail.

Personally, I prefer the black one which comes into view in the video at about 3:00. The tender is better proportioned to the locomotive.

Looking to put a Lionel GP20 body on a Williams jeep chassis. With some correct detail parts like cooling fans, etc. it would be a nice piece. Except for the fact that the cab sits so far back that the front truck can motor obstructs and the body can't sit back where it's supposed to be. Lionel's GP20 body is made correctly and is simply a GP7 or 9 body with a low nose just like the real ones. Ok, my question is where can I get low enough profile can motors with similar if not identical properties to the ones Williams uses. Lets not be too concerned with exact measurements at this point. If I get a lead on something I will try and figure out if they will fit myself. I think the shafts are 2mm.

The other part is whether it's possible or feasible to remove the worm from the shaft on the factory motors. On this, I know nada.

Guys, I have the 1990 scale Hudson and would like to run it with TMCC. Even though the Hudson has the open frame motor, would ERR be the best option to add tmcc to it? Could it smooth out performance?

I rather not replace the open frame motor with a can motor. Has anybody ever added ERR to this Hudson and how did it turn out.

Dave

david1 posted:Guys, I have the 1990 scale Hudson and would like to run it with TMCC. Even though the Hudson has the open frame motor, would ERR be the best option to add tmcc to it? Could it smooth out performance?

I rather not replace the open frame motor with a can motor. Has anybody ever added ERR to this Hudson and how did it turn out.

Dave

Dave, I did one Hudson with ERR AC commander, although it ran smooth(ish) it does not compare to the countless other hudsons and mohawks I have swapped out the AC motors for Pittmans and ERR cruise M.....now they run super smooth, even at a crawl......the Hudson I did the AC commander is slated to get a pittman…..it just doesn't compare!...………………...Pat

It'll run better than it runs now, but like he says, not nearly as well as with a decent can motor and cruise. ![]()

@harmonyards do you have any photos of your Pittman motor swaps? (I'm familiar with the smaller Timko motors which are NOT Pittmans, no thank you on those!)

I get the impression that the grey 785 and 1-700E are happiest on O42 or wider curves, possibly due to differences in the wheel gauge, flanges, etc., of the open-spoke wheels and chassis. In the case of the 1-700E you would also also have to change out the pilot truck for one with undersized wheels. There are other threads here on the Forum and elsewhere about tuning up these 1980s Hudsons so they don't growl so loudly.

So... If you're determined to run a scale-sized Hudson on O31, I would stick with the sintered-iron wheel models like the 783, 784, or a real Postwar 773 if you can afford it. They all have a lot of overhang, and will be relatively noisy on their best day. Unless you're totally driven by nostalgia, I would go with a LionChief Plus or RailKing model for more appropriate size, sound, and speed control. My $.02.

Jim Policastro posted:Joe,

Some run better than others. Just give it a good lube before running. All the Hudsons seem to have no problem with 031.

In action at about 1:30 in this video of mine:

Jim

Jim, great locomotive and layout. Thanks for sharing the video.

Ted S posted:@harmonyards do you have any photos of your Pittman motor swaps? (I'm familiar with the smaller Timko motors which are NOT Pittmans, no thank you on those!)

I get the impression that the grey 785 and 1-700E are happiest on O42 or wider curves, possibly due to differences in the wheel gauge, flanges, etc., of the open-spoke wheels and chassis. In the case of the 1-700E you would also also have to change out the pilot truck for one with undersized wheels. There are other threads here on the Forum and elsewhere about tuning up these 1980s Hudsons so they don't growl so loudly.

So... If you're determined to run a scale-sized Hudson on O31, I would stick with the sintered-iron wheel models like the 783, 784, or a real Postwar 773 if you can afford it. They all have a lot of overhang, and will be relatively noisy on their best day. Unless you're totally driven by nostalgia, I would go with a LionChief Plus or RailKing model for more appropriate size, sound, and speed control. My $.02.

Ted, Im getting set to do another scale Mohawk this week, Ill post up pictures of that swap (similar drive line as the AC Hudsons) I can tell you this much, Pittman swaps in just about all of these models aint for the faint at heart....If I didn't own my own machine shop, these could turn into a hot mess quick!....but Ill post up some pics so you can see how I do it....Pete AKA Norton also does these swaps too....his Vandy with a Pittman swap is a work of machining art!...perhaps he might see this and chime in without trying to Hijack Joe's thread.....I think this thread started out as a Williams VS. Lionel Hudson thread....I just landed a good deal on a bunch of 9000 series Pittmans….so let the swapping begin!...……………...Pat

Thanks Pat! Yes I'm familiar with how Pete (Norton) shoehorned one into his Commodore Vanderbilt. I lack the machine tools or skills, but would be all over a pre-packaged "kit" to do this myself. Can motor and no rubber tires? Why, yes thank you!!

Ted S posted:Thanks Pat! Yes I'm familiar with how Pete (Norton) shoehorned one into his Commodore Vanderbilt. I lack the machine tools or skills, but would be all over a pre-packaged "kit" to do this myself. Can motor and no rubber tires? Why, yes thank you!!

indeed...my 6-18064 mohawk has been "Pittmanized" and has a fan driven smoke unit that runs on the cam lobe for chuffs, real dramatic tuggin a long freight working the slip...Ive got GRJ's super chuffer and chuff generator slated to go in that model, so im sure that unit aint gonna do nothing but get wayyy better than it is now...the exhaust on the wheel slip is something to see!...workin her out of a wye is a ton of fun draggin 60 cars!...…………...Pat

Thanks for the replies folks.

A couple more notes, based on experience with my own 785:

Wheel gauge is important. The postwar service manual specifies 1.235", measured at the point where the flange meets the tread of the wheel, for the 773. My 785 was just slightly binding on Super O curves (though it did alright on O-31 tubular). I found that it was over gauge by .016" or 1/64 on the rear drivers, and about half that on the front. Adjusting the gauge to spec solved that problem.

It was also noisy. That coffee-grinder sound. The problem was that the shaft which carries the worm has too much fore and aft play. I fixed that (for the time being) by rotating one of the rectangular bronze bearing blocks 180 degrees around the shaft. Since they are made to go in only one way, doing this will actually alter the position of the bearing laterally. With the fore and aft play all but eliminated, it quieted right down. Now, that's the quick and dirty fix. What I need to do, per the manual, is pull the drive coupling, add some thrust washers to take out the play, and press the coupling back on.

I find this engine to be an excellent puller, especially when you consider that it has no traction aid at all. But does like its volts and amps. This is the only engine I own that I can run with the ZW wide open and wish I had more to give it.

Here's my Hudson pulling the famous TCA work train.

Mark

Attachments

harmonyards posted:Ted S posted:Thanks Pat! Yes I'm familiar with how Pete (Norton) shoehorned one into his Commodore Vanderbilt. I lack the machine tools or skills, but would be all over a pre-packaged "kit" to do this myself. Can motor and no rubber tires? Why, yes thank you!!

indeed...my 6-18064 mohawk has been "Pittmanized" and has a fan driven smoke unit that runs on the cam lobe for chuffs, real dramatic tuggin a long freight working the slip...Ive got GRJ's super chuffer and chuff generator slated to go in that model, so im sure that unit aint gonna do nothing but get wayyy better than it is now...the exhaust on the wheel slip is something to see!...workin her out of a wye is a ton of fun draggin 60 cars!...…………...Pat

Pat, I too would love to see how you mounted your Pittman. I just picked up Timko Conversion along with the typical 385 Mabuchi, second hand. The motor with its flywheel is almost the same length as a 56 mm Pittman. Also the Pittman may be small enough in diameter to fit where the Pullmor does on a '90s Hudson type frame. May require only shaving a tenth or two off the back of the frame.

Pete

Norton posted:harmonyards posted:Ted S posted:Thanks Pat! Yes I'm familiar with how Pete (Norton) shoehorned one into his Commodore Vanderbilt. I lack the machine tools or skills, but would be all over a pre-packaged "kit" to do this myself. Can motor and no rubber tires? Why, yes thank you!!

indeed...my 6-18064 mohawk has been "Pittmanized" and has a fan driven smoke unit that runs on the cam lobe for chuffs, real dramatic tuggin a long freight working the slip...Ive got GRJ's super chuffer and chuff generator slated to go in that model, so im sure that unit aint gonna do nothing but get wayyy better than it is now...the exhaust on the wheel slip is something to see!...workin her out of a wye is a ton of fun draggin 60 cars!...…………...Pat

Pat, I too would love to see how you mounted your Pittman. I just picked up Timko Conversion along with the typical 385 Mabuchi, second hand. The motor with its flywheel is almost the same length as a 56 mm Pittman. Also the Pittman may be small enough in diameter to fit where the Pullmor does on a '90s Hudson type frame. May require only shaving a tenth or two off the back of the frame.

Pete

Pete, I have plans to do the next 18009 mohawk, it was late arriving (thanks fed-ex!) so I didn't get started on that one as of yet. I will pop the shell off the 18064 mohawk (virtually the same mechanically) and snap some pictures of that mod for you. I'll make a whole new thread on that build so we don't jam up Joe's thread...LOL That unit is due an inspection and cleaning anyways, so it wont be a problem....As you well know, cramming the Pittman in these units requires shaving the shell casting but it aint ugly....there's enough material there to relocate the rear chassis mounts and not make a mess out of it....I don't do hack work!...when I saw your vandy swap, I said to myself, that's a clean install...I must be on par with that level of quality....its a pride thing!....![]() …………………….Pat

…………………….Pat

@gunrunnerjohn posted:Timko makes DC motor conversions for these, and then I can give you a dynamite command upgrade with fan driven smoke, great sounds, etc.

I know this is an old post but are the upgrades still available for this engine.

Pat @harmonyards does a great Pittman upgrade for this engine, night and day over the coffee grinder it has now. ![]()