Trust is important to me, and the three Repair Trips and damage to the new CSX F40PH #9999 has brought a break in the good faith relationship I thought I had with Dean at Lionel. We both appear to mistrust each other.

Timeline Speculation: I purchased the CSX F40 PH #9999 from Nicholas Smith's website this past summer of 2018.

It arrived with a short due to a pinched wire behind the engineer at the middle body shell post. I opened the engine and wrapped the wires resolving the short. The Body Shell roof hatch to the Run/program switch would not open. I believe a roof ring was missing too.

1st trip to Lionel: The engine was to be inspected and checked for the wire above the front motor that was shredded on many of the F40PH engines. The engine was to be checked for any issue. According to Dave in an OGR post there were several things to look for.

The engine returned and the roof hatch would not open. I had to remove the Body shell to access the run/program switches and volume pod. The smoke was also not working now.

2nd Trip to Lionel: The engine roof hatch was repaired and the smoke was fixed.

The engine returned with the smoke working and the hatch opening. There was a light blue spot on the roof. The volume was very soft, so I turned the Volume pod and it did not raise or lower the volume. I did NOT open the engine because the rood hatch now could be opened for programming. I called Lionel and received the third RA for this engine. Perhaps Body shell post damage was stating, but insignificant for the tech to put in his notes. I did not receive a service report on the second trip back to me. There was NO Lionel paperwork.

3rd Trip to Lionel: The engine arrived at Lionel with a dead short that it did not have when I sent the engine back. Dean emailed me to say that someone had messed the engine up badly, and it was not his technical staff. The sound Volume Pod was unplugged in the engine. The engine was missing several screws, and too big of a screw may have been used on the engine. (Side note: Whenever I open an engine, it is on a clear table and all parts are placed in Zip Lock plastic bags or organized piles indicating where they were removed from, so reassembly is correctly done.)

I am guessing that the unplugged Volume was missed at Lionel when the engine Roof hatch was repaired on the second trip. OR the Return shipping on the second trip loosened the plug due to rough handling. The Third trip back to Lionel could have also caused the damage. I did not open this engine since the first time it was sent to Lionel and returned to me with a still unrepaired, stuck roof hatch. I did not notice missing body screws when I sent it in for the third time.

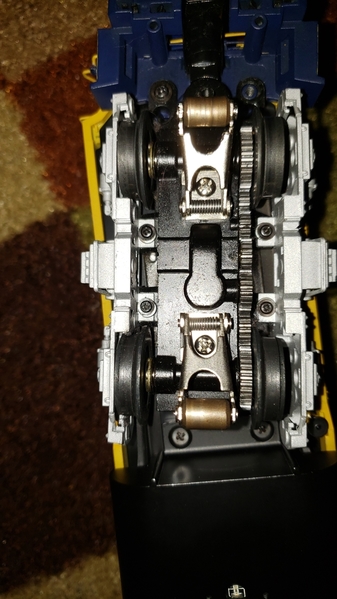

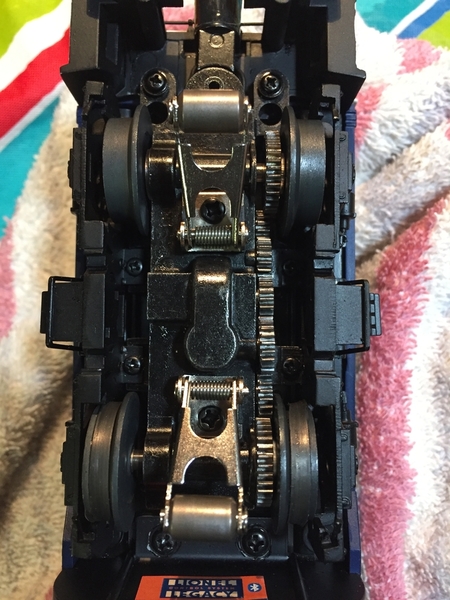

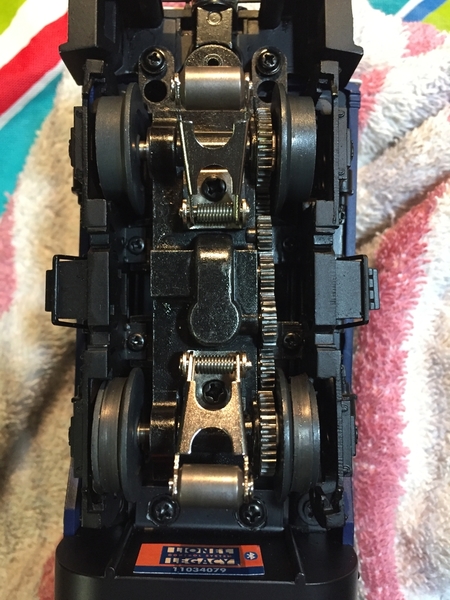

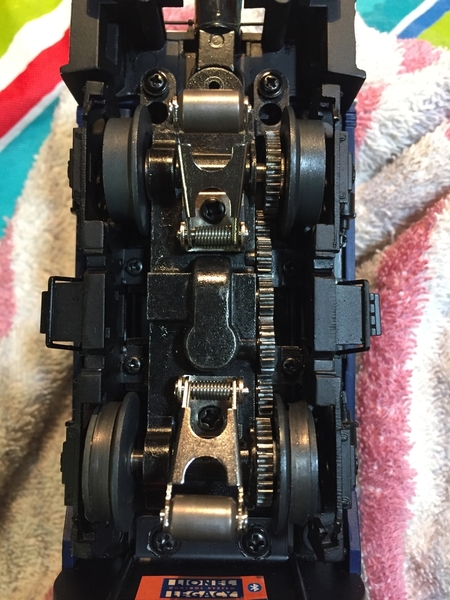

3rd Return of Damaged Engine: The pictures in this post show an engine with all the Shell Body Posts broken from the engine shell. Some posts look like they may have been previously broken as Dean's email indicated. They have chips at the base where they fasten to the chassis.

I have emailed pictures to Dean. I, and maybe you too, can no longer get service without Dean's approval. Lionel changed its way it takes returns as of mid December 2018. The new policy as explained by Katie is "1. Dean must email Service that they can issue an RA. 2. All RAs have to be approved by Dean. Some type of internal number follows Dean's communication to Katie and the service crew." Unfortunately, Dean is never available. Dean is not in his office. Dean is on vacation. I must email Dean. Dean must email service.

The policy was designed to slow down the number of repairs to Lionel, as it was explained to me. There is some kind of irony that Lionel's email address is "TalkToUS". I am sorry. I could not resist this comment.

Hopefully Lionel and I will mend his fractured relationship. My Mom's cousin who served as a judge and state representative always instilled the importance of the truth and open honesty. My youth was spent as Master Councilor of my DeMolay masonic youth Chapter. As a leader, Degree of Chevalier, and long time teacher, I swear these statements are the truth.

The truth is being eroded today, thanks to American politics. Everyday I get a telephone call from a salesman who is offering me a back brace, leg brace, warranty program, etc. that they say I inquired about. I never contacted them. Lying will erode the American way of life and eventually threaten democracy.

Sincerely, John Rowlen