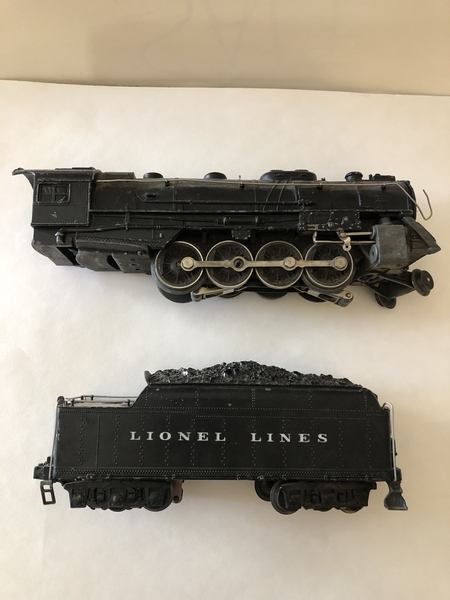

This is a recent acquisition from “mowingman” who happens to live just 30 minutes away. It’s a “in need of a total restore but fabulous engine and tender combo”. Probably a 47 or maybe a 48. Not quite sure but mowingman thought the earlier. In the transaction I got to actually meet in person a fellow forumite and tour his setup to boot. My train efforts pale in comparison to him as well as to most of you! Great fun.

The engine has some wear but I think it will come out real nice. Still barn fresh. Missing a couple of hard to find items (boiler front and steam chest) but after checking with the TrainTender and others I found TrainWorx In Pennsylvania had both after a referral from Harry Hennings. The boiler front is a new repro hard casting that TrainWorx is just starting to crank out. I’ll share that when I get it.

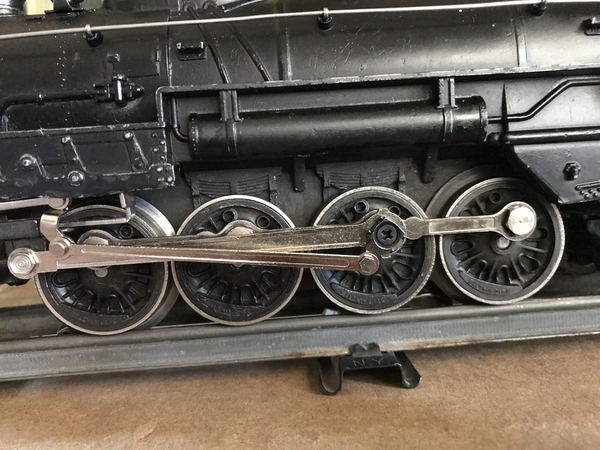

Photos below. At this point I’ve completely torn down the engine. It did not run. It was so gunked up the brushes were stuck up in the tubes. Did not seem to be oil on the brushes but was fouled with carbon black. They cleaned up nice.

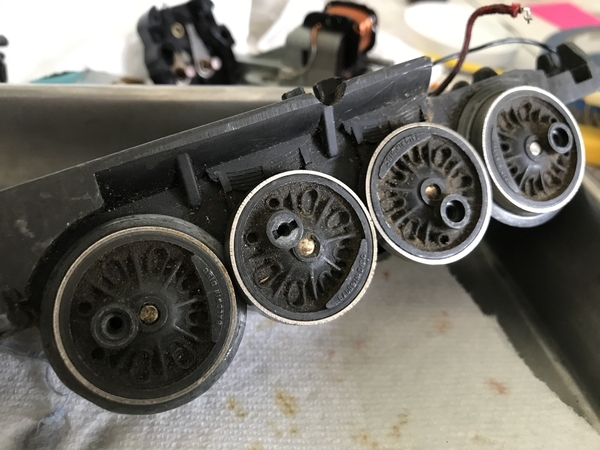

Test runs smooth as can be. This is the loose bearing variant 671m-1 I think. Anyway it had 11 bearings total. I reassembled it and then remembered I had a leftover bearing cage with five ball bearings from a 726RR rebuild. So I redid the setup with 11 bearings in the rear and the bearing cage in the front. It seems to run better with more bearings. Fit up really well and with one extra shim on the front it has a hair under 0.01” axial play. Much better than my other motor.

NOW MY QUESTION and the reason for the post: on both of these engine rebuilds I have not been able to completely remove the armature. I see in other threads that it can be done. For me the shaft end with the worm is always too large in diameter and it simply cannot pass through the front oilite bearing. What is the proper procedure?

In the end feel fine with my result as I thoroughly flushed the rear with oil. Same with the oil hole and front bearing. Then reloaded the shims and loose (rear) and caged bearing (front) with grease. Any thoughts welcome...I thought about spinning it under power and hitting the worm with a 600 grit wet-o-dry sandpaper but in the end got lazy.

The first photo used with permission from Jeff Thomas, all others mine.