I’ve been having trouble with Lionel Fastrack sections losing power because of bad track section to track section connections. Because my kids and I are slowly building/evolving our layout I want to be able to disassemble and reassemble the Fastrack sections. I therefor do not want to solder the sections together. I’ve done the recommended cleaning and bending of the middle tabs but power lose regularly happens.

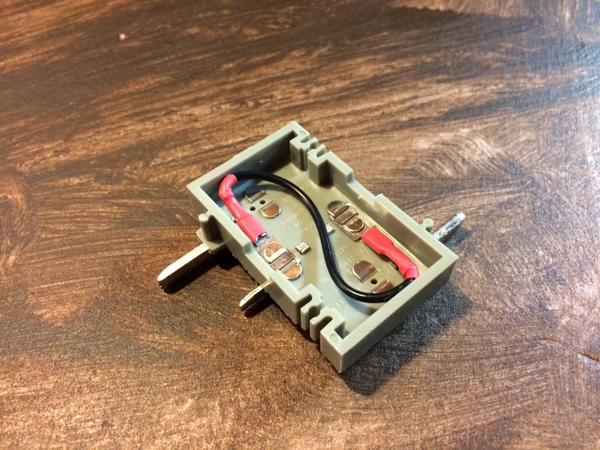

I want to used spade connectors to connect track section to track section. Most Fastrack only has the one male connection for the center and on connection for the outer rail. So you can connect two sections at most using those connection points.

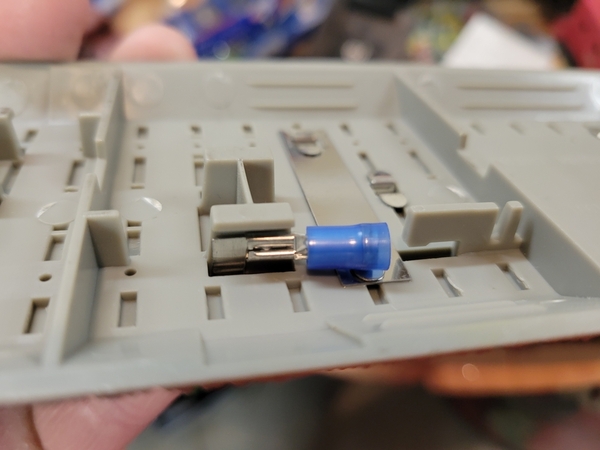

I saw that the small Frastrack sections(photo below) have male connection points that could work if in installed on the end of a regular 10” section. I will have to bend the track tabs up install and the. bend them back down.

The question is where can I get some of those male tabs to install? (I already have wire and the crimp on female spade connectors to attach to the wire.)