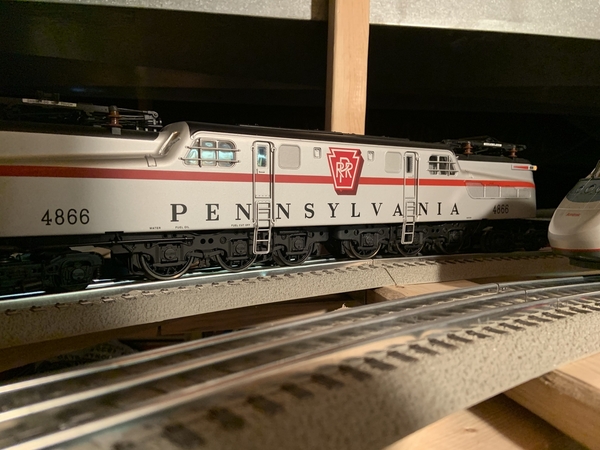

I could outline the problem, but you can see it in all its glory on the O-27 forum under GG1 zinc pest.

I am moving the discussion here for two reasons - one, we are discussing a scale model, and two, I need to be able to quickly find this thread for updates.

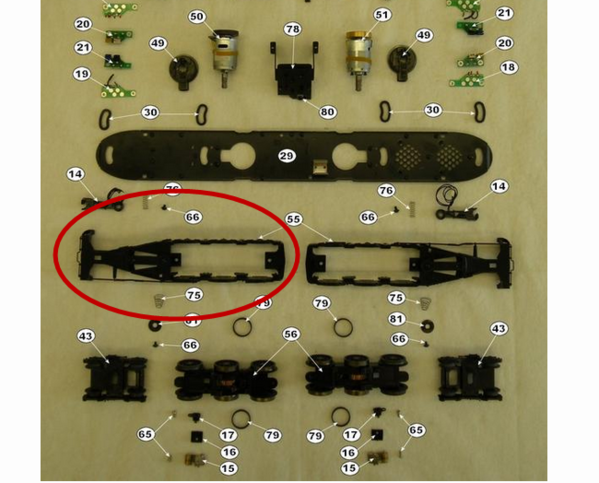

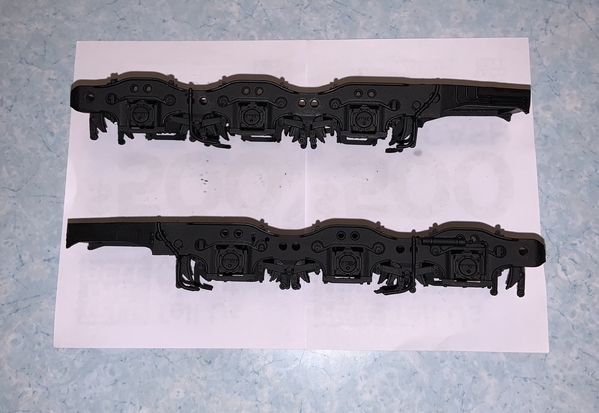

I have in my possession a pristine, uncorroded part. Photos will be forthcoming. The problem is twofold - one, a lot of these parts are falling apart, and two - Lionel says the mold has been modified and it is no longer possible to reproduce the part.

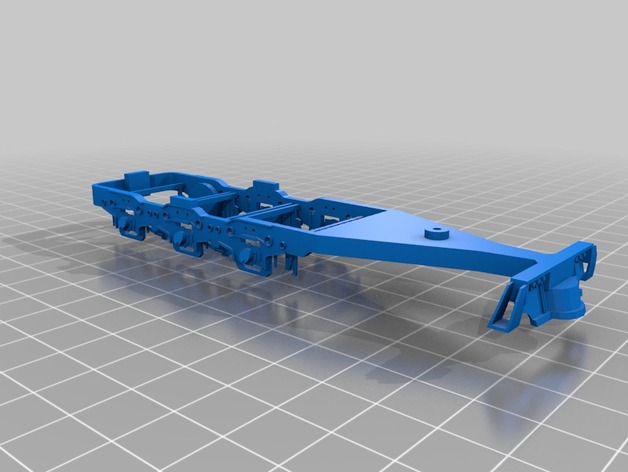

Dean Brasseur, of Lionel, has told me that it would be ok to reproduce this part. The way that is done is by making "no-shrink" flexible molds out of something like RTV, then popping wax parts out of the molds, and finally "investing" these wax parts in plaster. Then the wax is melted out and molten brass is poured in.

But there is another way - we can use the Wolfer/Duddy patterns with some changes in the tongue area, and have an equally scale part. The only problem there is making the "tongue" masters, and I can do that easily.

Decision time - give me a month. Cost? Not sure - my time will be free, and I have committed a hundred bucks to the effort, which does not have to be reimbursed (and remember, I already have enough brass/bronze GG1s; this is just an intriguing project).

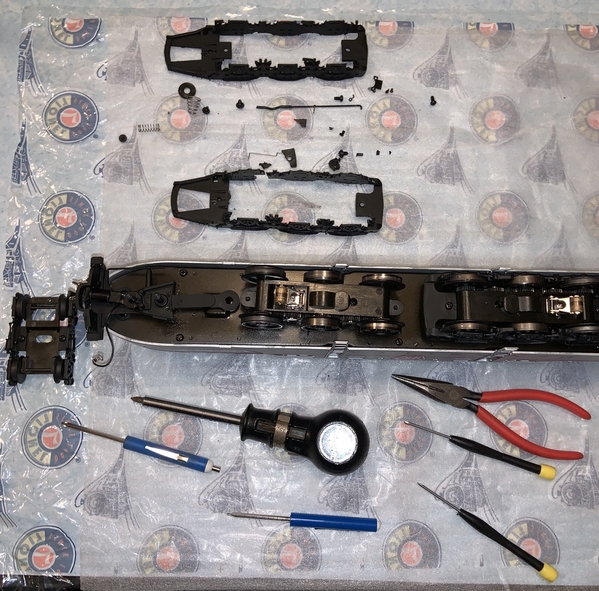

If we do go with pulling molds off the Lionel part, I would need to do it in four pieces. Bob C. (I have his permission to use his forum name, but not sure what it is) has lent me a pristine part. I cannot cut this one. And I have an offer of another hundred bucks to get started. So if the decision is to cut before making exact molds, I will need some further arrangements.

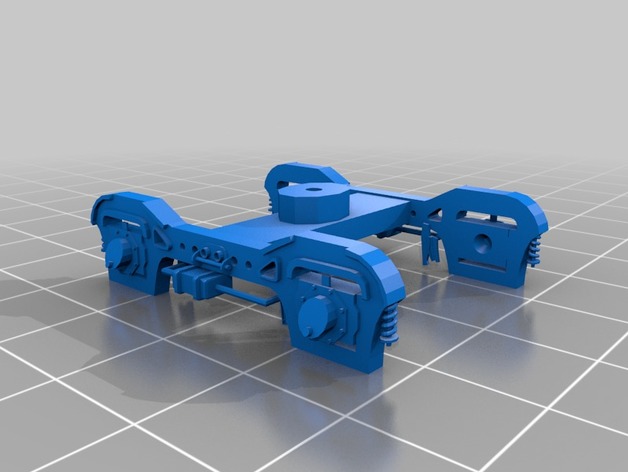

Tomorrow I will take some tripod photos so you can see what is what. Then perhaps we can vote on which way to go. The Wolfer/Duddy castings have separate journals and brake shoes, so more assembly will be required, driving up the cost for those not handy with such finicky assembly.

I think that is enough info to start. Please, if you have time, count up how many of these we really need due to part failure. Each "locomotive set" would be two Lionel castings, or four sideframes, two tongues, and a rear spacer.

Please tell me the screwed-on pilot/coupler part is not falling apart? Please?