Hi All,

Not sure if this is the correct place but I have not seen anybody talking about building modules.

I have been busy with module construction this weekend.

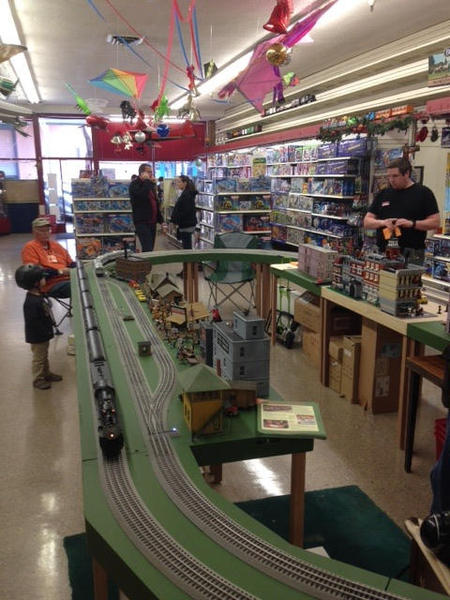

As I am in the UK I have taken the decision to build a complete modular layout. In other words the minimum size. 8 corner modules and 2 straights. Hopefully when other UK club members see it they will join in and build a module or two of their own.

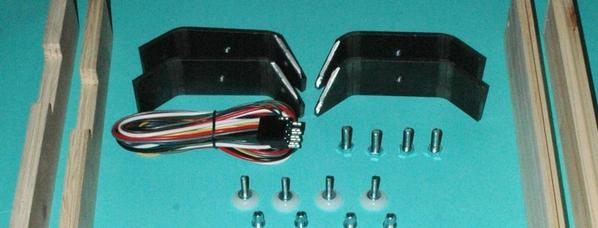

I ordered 3 modules from LCCA. One straight, one reverse corner and one full corner. This was to speed up constuction by using the components as templates.

I happy to say this has worked very well and I was able to complete constuction of all the frame components this weekend.

Ok I cheated slightly by getting the pine sized and rebated at a timber yard. I also got the Plywood ends sized.

This ment I could use my Mitre saw to cut all the angles and cut the ply sections to length.

I decided to dust off my biscuit jointer. Had it about 5 years and used it twice (kitchen worktops![]() ). Cut all the joints in the pine and the Ply.

). Cut all the joints in the pine and the Ply.

LCCA Kit supplied on the left. I have the notches for the Rotolocks to cut next.

Found a UK supplier for the Rotolocks as well so all in all a productive weekend![]() .

.

Nick