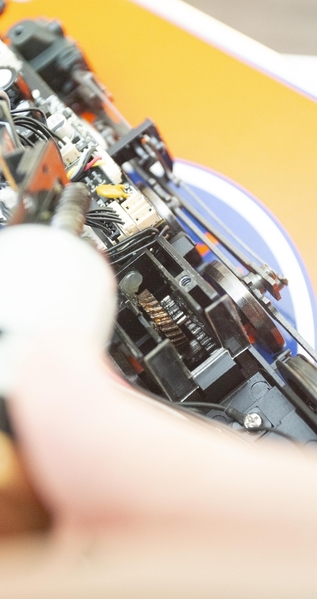

Ok boys & girls, ….I’ve had some great correspondences with a buddy & fellow machinist in regards to the Mikados, ……specifically, the 2012 model year issue,….after some careful measurements, and some back & forth, these Mikados have the same set up as the K4s’s …..so in other words, the Mikes could potentially suffer the same fate as the K4’s ……again, our example for inspection is a 2012 model……later on, I’ll get some pics of the inspected model, and post up findings…..

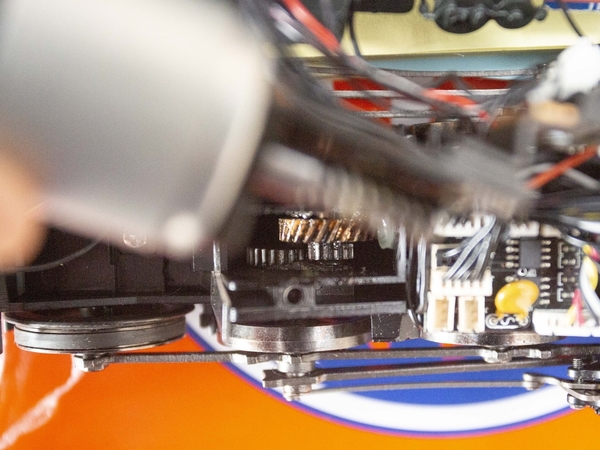

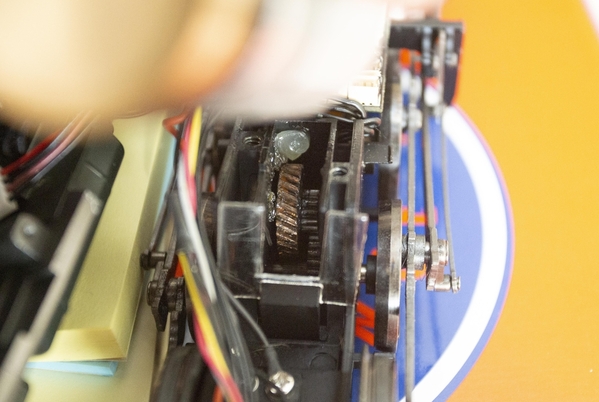

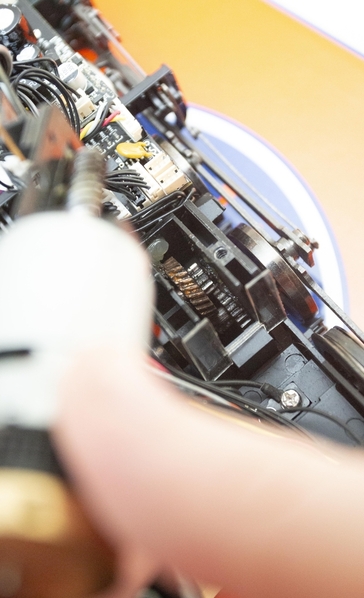

Let’s jump back for a second, and talk about where this started, and what I feel is going on, and hopefully shed some light for folks,…..when we looked at a couple K4s’s, that were already damaged, what I noticed is the bushing they used to keep the worm wheel on track in the center where it belongs, can literally dig itself into the intermediate shaft bushing. ….I believe both the spacer bushing and the shaft bushing eat one another, not just a one sided game ……the combination of wear is what results in the shaft walk…….from an engineering stand point, the intermediate shaft bushing can not withstand being attacked from a side load….it’s strength is only in the shaft riding inside of it on a thin film of lubricant……in a nutshell, and to put it in layman’s terms, the shaft spacer and the shaft bushing are eating one another…..

Dave, can you add the 2012 Mikes to the fail list?….please?…😉

Pat