Pat asked me to add this additional Legacy K4s problem and solution to the thread.

Legacy K4s pickup roller upgrade

I started another thread to raise the issue I was having with my Legacy K4s stalling on Atlas #5 turnouts. The cause is the pickup rollers are spaced too close together causing loss of rail contact when moving through larger turnouts. Since it has an IR wireless tether, there is no power sharing between the locomotive and tender. The distance between the 2 rollers on the locomotive is short 2 7/8". The Atlas #5 turnouts have a gap in the center rail of approximately 3 1/2".

This type of problem has been solved in various ways:

1. Add a power tether between the locomotive and the tender

2. Add a 3rd pickup roller to the locomotive

3. Install Atlas Atlas 6924 Non-Derailing O Gauge Switch Relay Circuit Board to power the points

I didn't really like options 1 and 3, and for option 2, a 3rd pickup would have to be added to the pilot or trailing truck. Can that even be done without causing the truck to derail?

I found another solution: install longer pickup rollers. Fortunately, there is room swap out longer rollers to bridge the gap.

Here are the 3 pickup rollers I was working with. Top to bottom they are from:

Legacy K4s (stock pickup)

RailKing Hiawatha Hudson (MTH BD0000005)

Lionel Scale Hiawatha Atlantic (Lionel cs-6308094150-p)

The first 2 are interchangeable, the longer one on the bottom requires that you also replace the insulator,

Install the medium length pickup roller MTH BD0000005 in the fore position. It should fit the existing insulator.

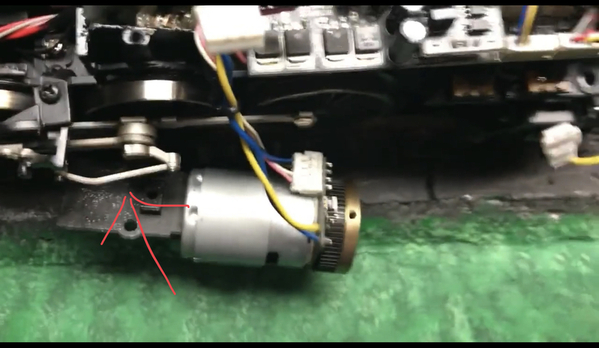

Install the long Lionel pickup roller SKU: cs-6308094150-p and its insulator SKU: cs-6101107335-p in the aft position. In order to fit, you need to trim the small tab on the insulator as shown here. I carefully split it with a #11 blade:

Here is the end result crawling in speed step 1 over back to back Atlas #5 turnouts. FYI - This locomotive has also had the Harmon Shops gearbox shim and driver bevel upgrades.

Bob

Edit: I mistakenly reported the Lionel pickups and insulators are sold in pairs. I was surprised when I received my order. They are actually sold singly and way overpriced ($10 for pickup, $1.10 for the insulator). Correction made.