Okay... I'm still kickin' around this hair brained idea. I've mentioned it here before (PW traditional sized steam and traditional sized diesels in an early 1950s urban setting), but I do have some questions that may help or hurt the idea. Either way will be fine. Here they are:

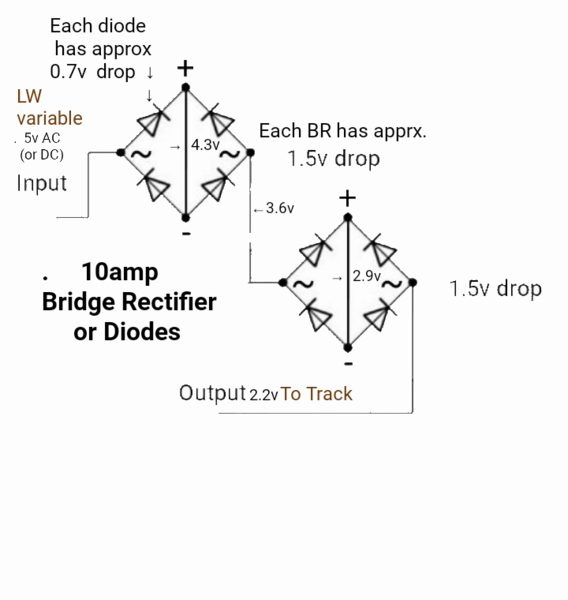

* What type of modern transformer would be good for better control of the PW stuff? (My old ZW came on at something like 6-8 volts, however the increased voltage during whistle/horn use was helpful.)

* I understand there will be limitations concerning the PW mechanisms, but will there be any improvement in the start-speeds and better overall performance using a modern transformer?

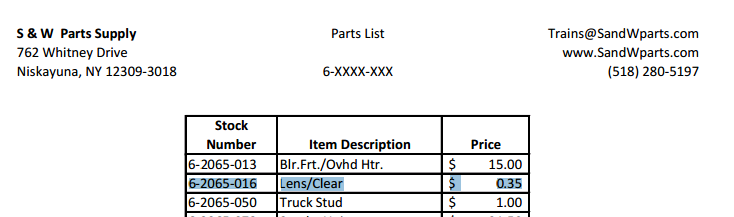

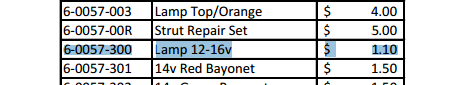

* Are repro parts still readily available for such things as Alco FA decals, windows, horns, etc, or steam engine boiler fronts, class light lenses, etc? Likewise mechanism parts?

The bench work from my previous small layout effort(s) is still in place here in my computer/hobby room. I have the HO equipment and track on hand to start a small urban type early 1960s layout thereon when the mood hits. I also have a dedicated out building that's ready to have a medium sized 1880s Colorado theme layout built in it once the weather is too cold (for me) to ride motorcycles. However, now I'm beginning to have my doubts about the small HO diesel layout in this computer room idea. I'm wondering if I would be better served to go with PW in the room such as I had started decades ago (see picture), but evolved away from it for several reasons. (Which reasons I have defined for myself and may be able to circumvent.)

Any input would be appreciated.

Thanks.

Andre