Hi all,

I'm new here. I just bought one of these K-line Hudson's off of ebay and am planning on doing the various upgrades regarding the electronics myself. Gunnrunner John's chuff stuff and ERR boards and fan smoke unit (likely MTH PS2).

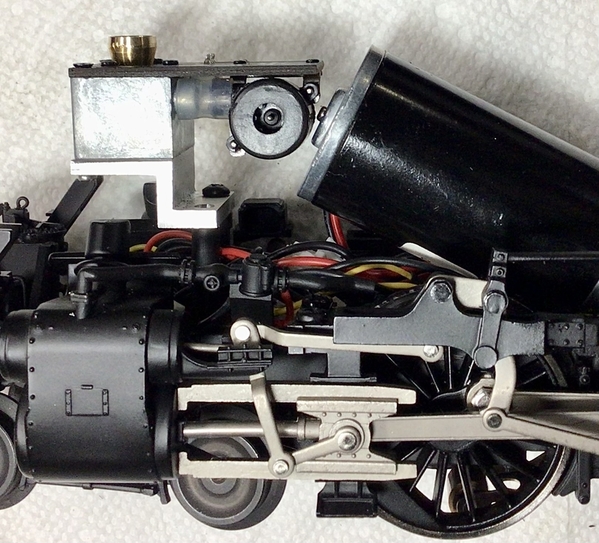

What I'm really wondering about is swapping out the existing motor for a more powerful one. I saw the thread where someone sent his out and documented the progress. My question is, can I just swap out the motor without doing the entire Chassis? I'd rather!!! LOL

If so, can anyone direct me to closest turbo charged monster of a puller? :^D

Thanks in advance for any intel!