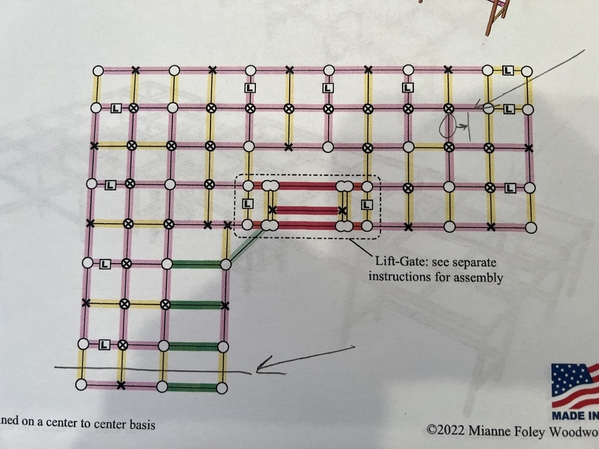

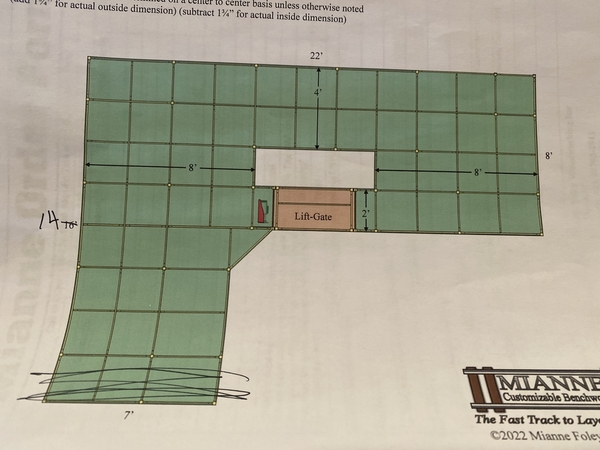

Hey guys... I literally have a basement to build as big a layout as I would like. Pretty excited about it. However, don’t have the time to build from scratch the framework. I am very interested in what Mianne looks like they can do.... has anyone had an experience with them or know someone who has? Looks like they have a great reputation. Any help would be most appreciated and any others to that do this time of framework to consider would also be appreciated.