@colorado hirailer: Mack railbuses and diesels huh? I'm already working on a small Mack diesel, but now you've got me thinking about railbuses. I visited the Pennsylvania Railroad Museum back in 2017 and took detailed photos of just such a vehicle. I've got to think about how I could fit a power unit into one of those.

@dkdkrd: I saw a picture of one of those Ann Arbor McKeens and was thinking of it when I read your post. I did some more research and started tinkering in Fusion... keep reading this post!

@AlanRail: Mass production and supply chain issues... ugh, sounds like my day job! I find that long prints are fine during the work week since I'm not home to play with my printer anyways.

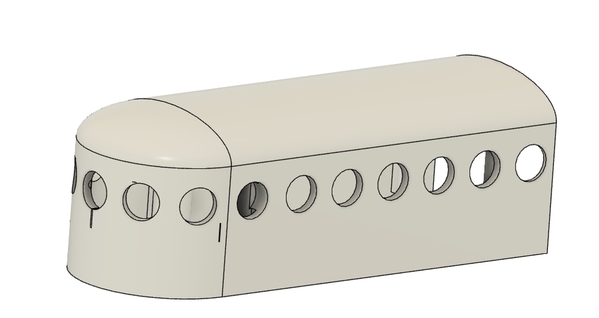

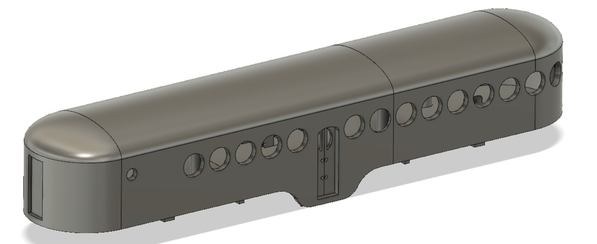

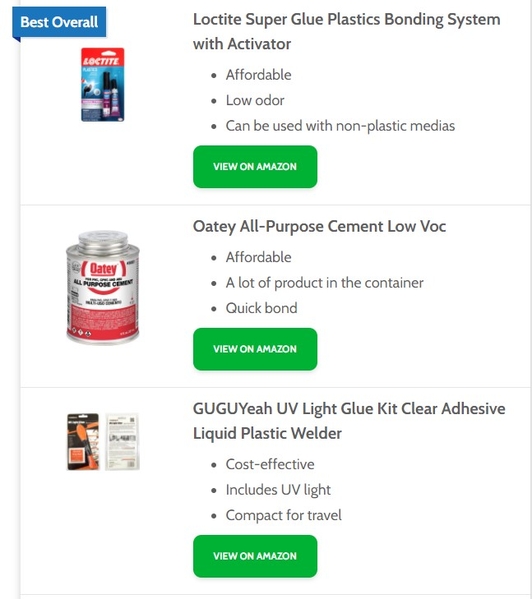

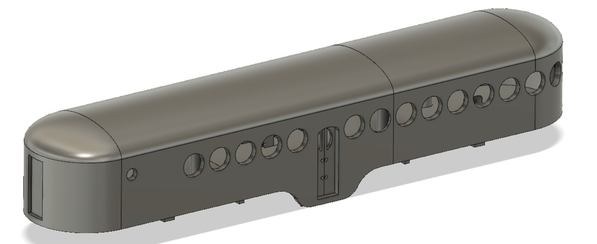

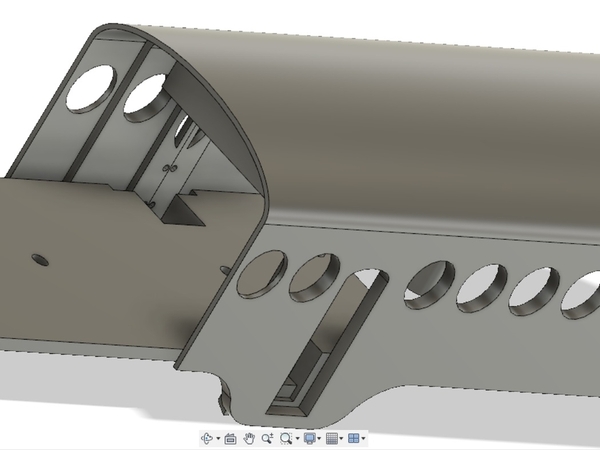

I've been spending a lot of my weekend and evening time developing more train kits, particularly for other McKeen rolling stock. I might be able to offer some of these next month if there's enough interest. The next of my new designs is a 48 foot McKeen passenger trailer.

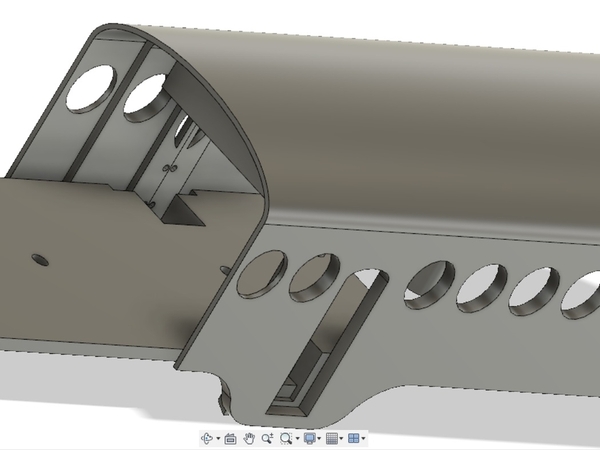

This kit will be 100% 3D printed, everything except the wheels and axles (I even have some trucks and couplers to supply with it). The body would be printed in 2 sections and the frame in 3 pieces. The chassis component you see is about 10 inches long-- my printer is just large enough to do this as a solid piece, but the floor takes 2 parts.

I designed some slots into the shell and frame so the passenger doors can slide open.

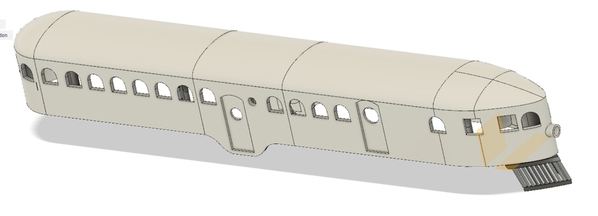

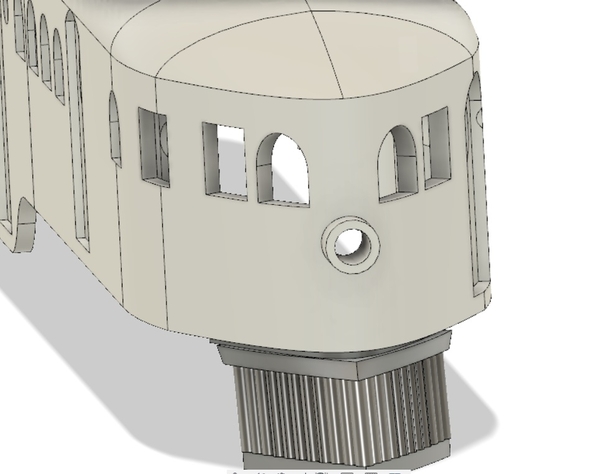

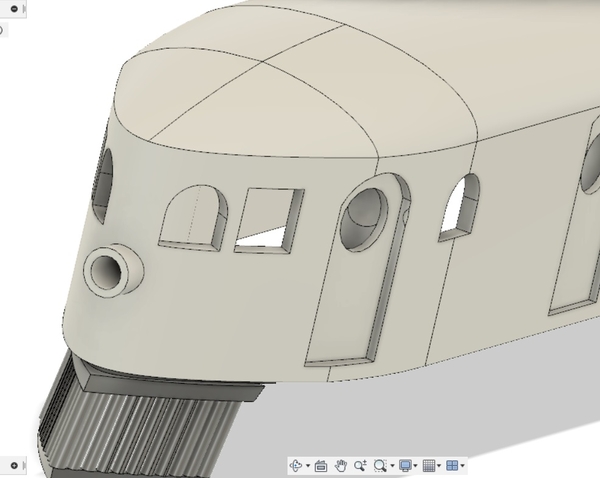

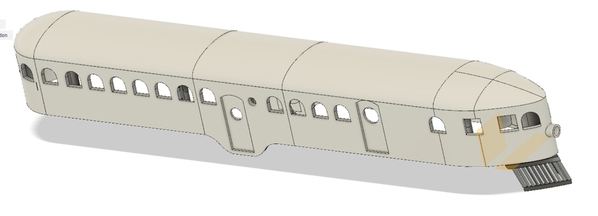

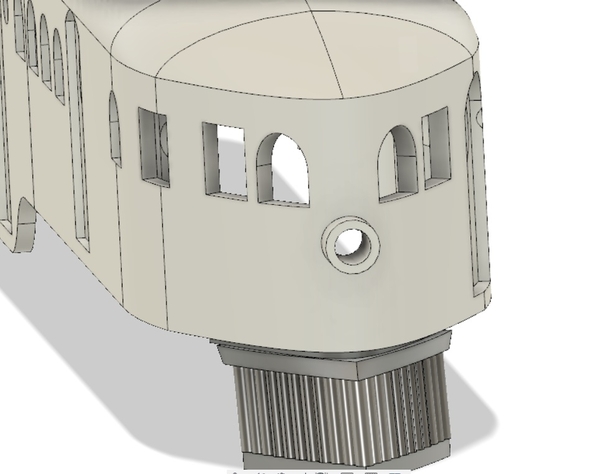

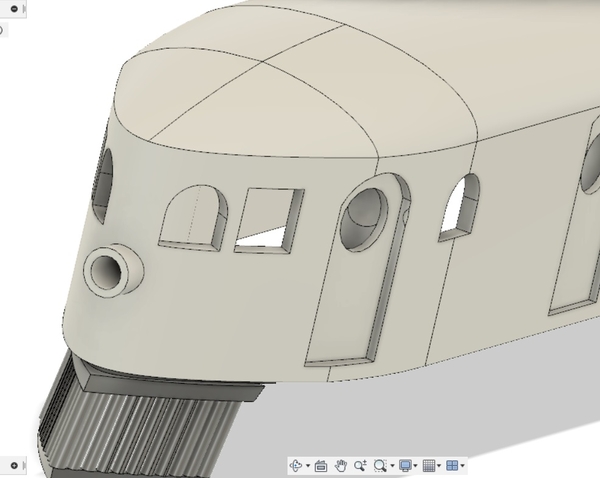

Inspired by @dkdkrd 's comment on the Ann Arbor variant earlier this week, I spent a couple hours branching my standard 70ft McKeen kit into the Ann Arbor McKeen.

Adding the arched windows was pretty easy but the parabolic nose was a bit hard to render. I had to utilize some new features in the Loft toolset to pull it off. I'm still not 100% sure I have the angles right but it's there.

I also added a driver's access door while I was working on the bow.

Let me know what you think!