The first production McKeen kit is ready to go-- on time and under budget! I am officially taking orders for McKeen Car body conversion kits!

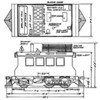

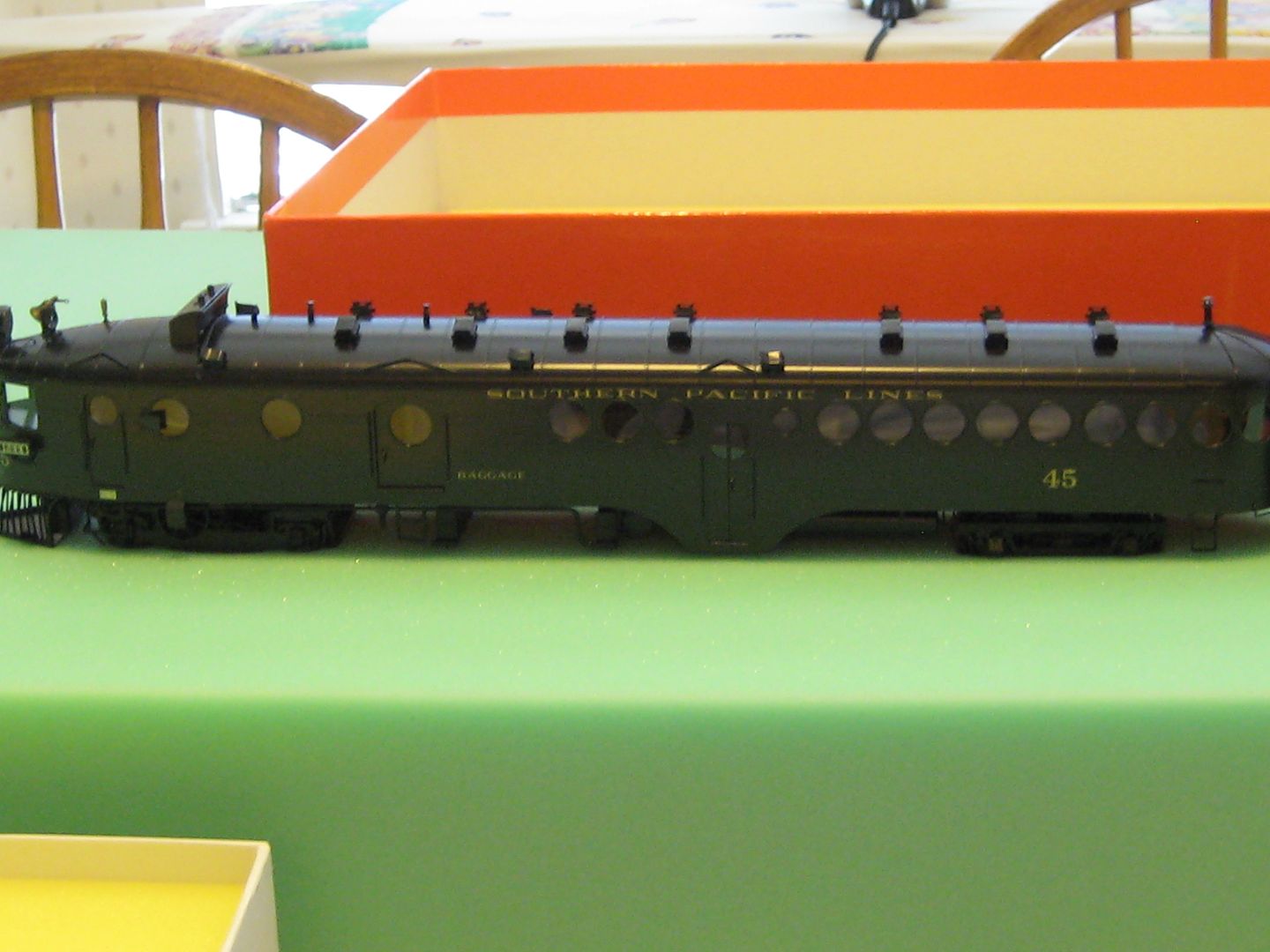

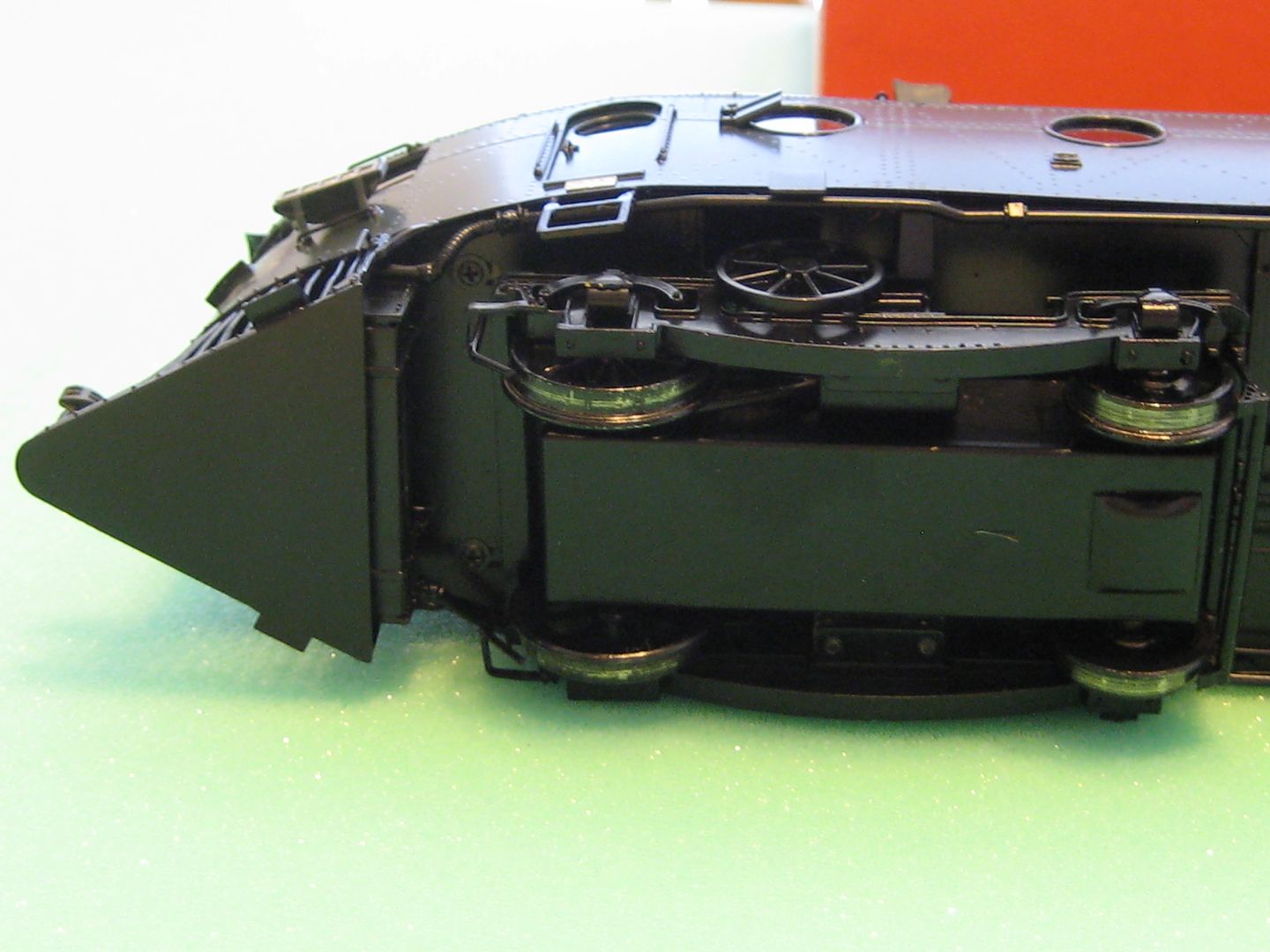

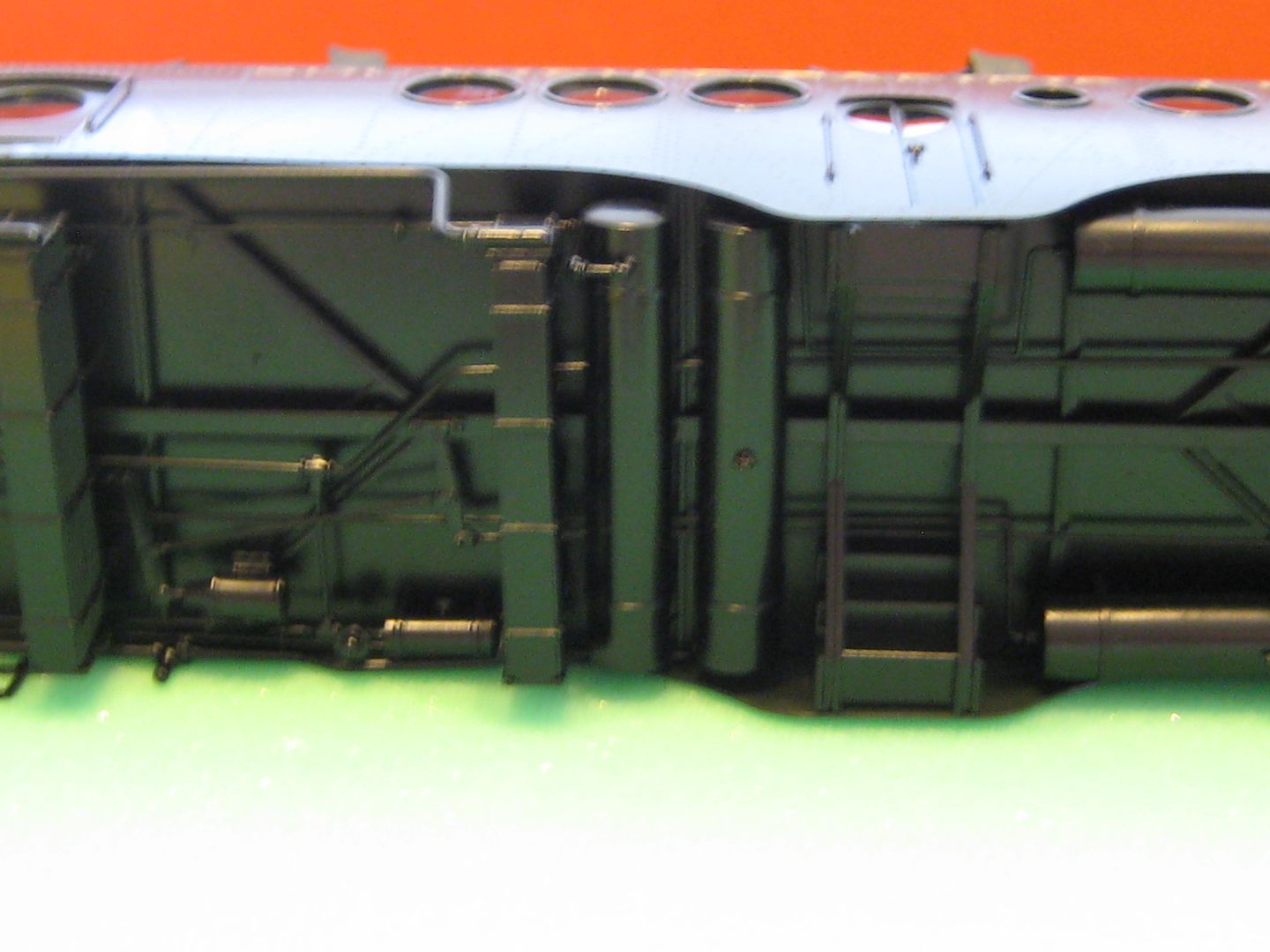

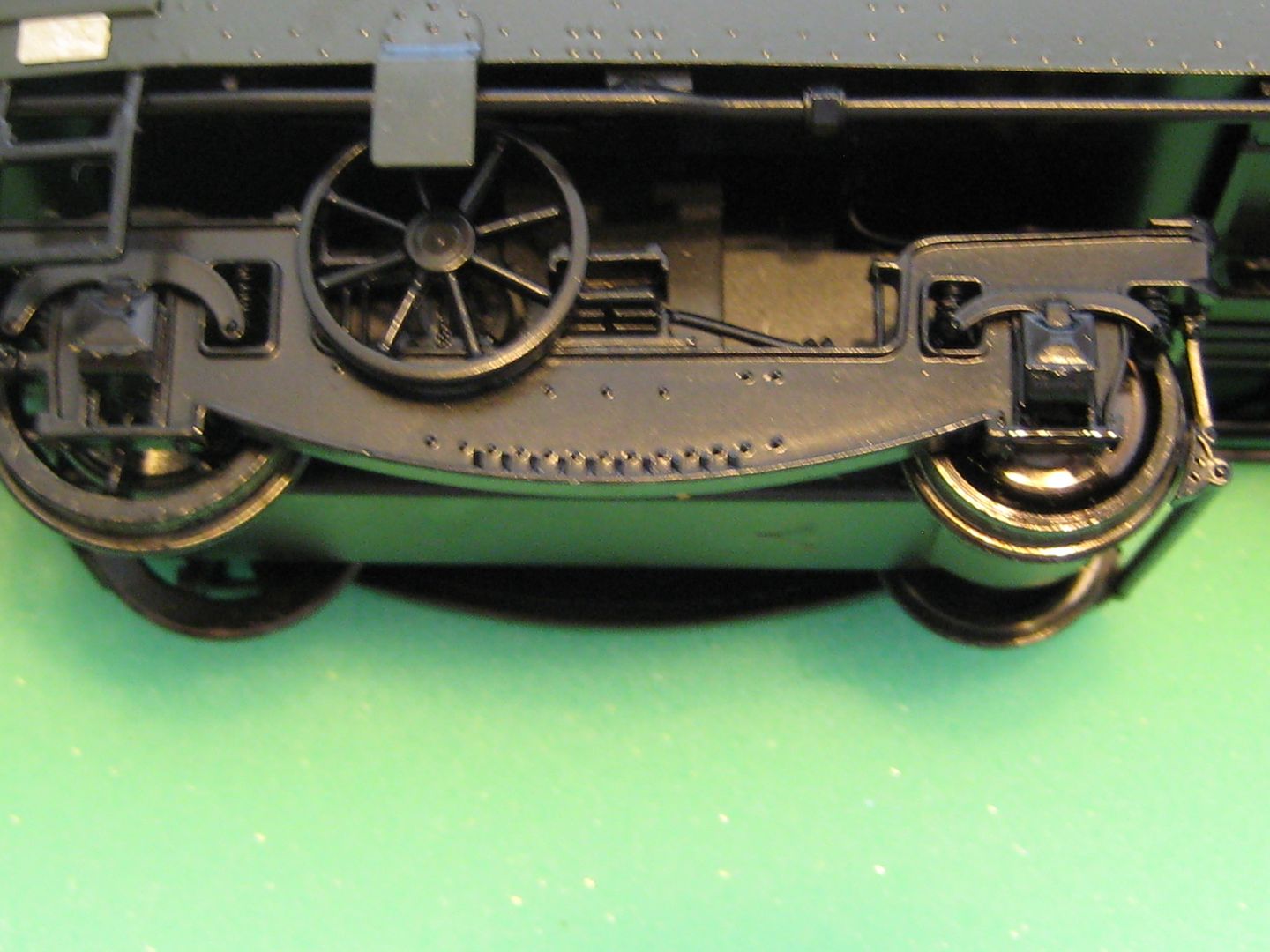

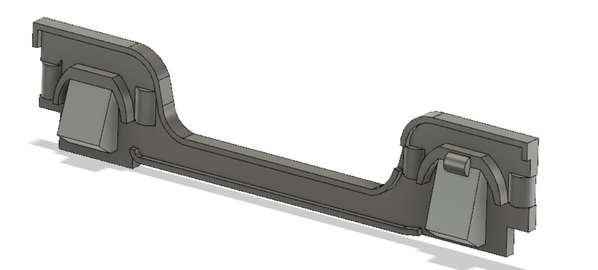

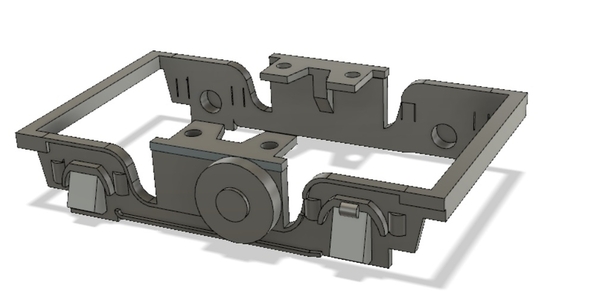

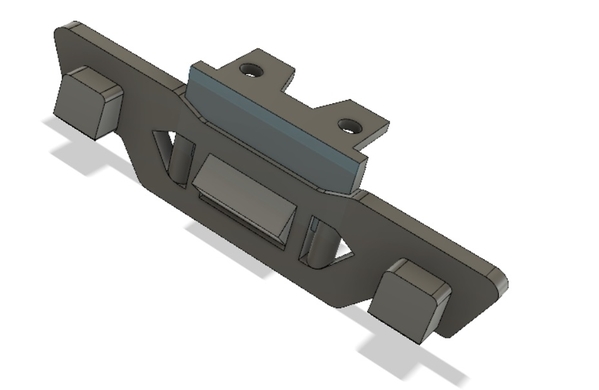

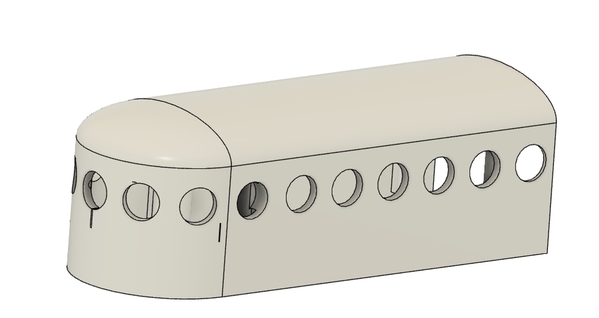

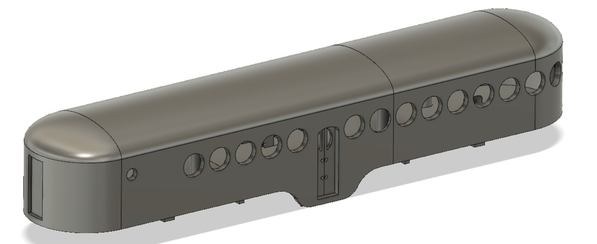

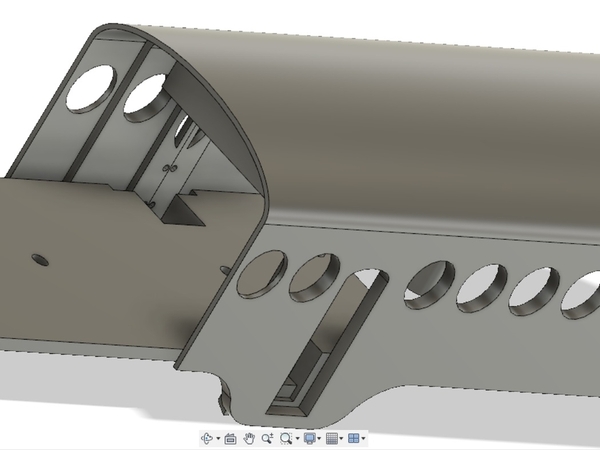

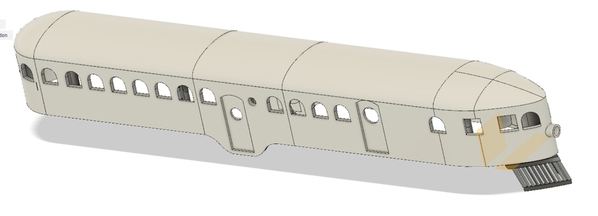

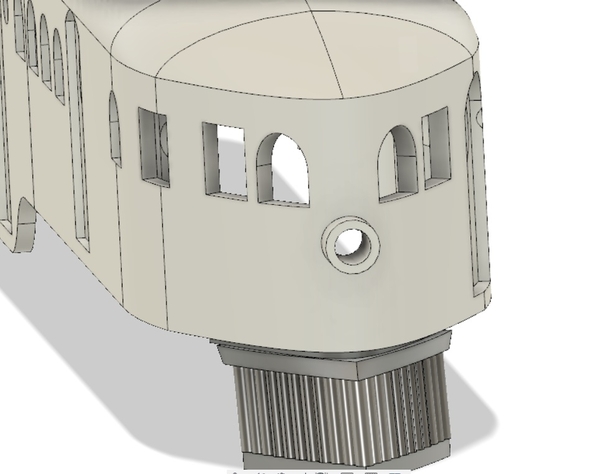

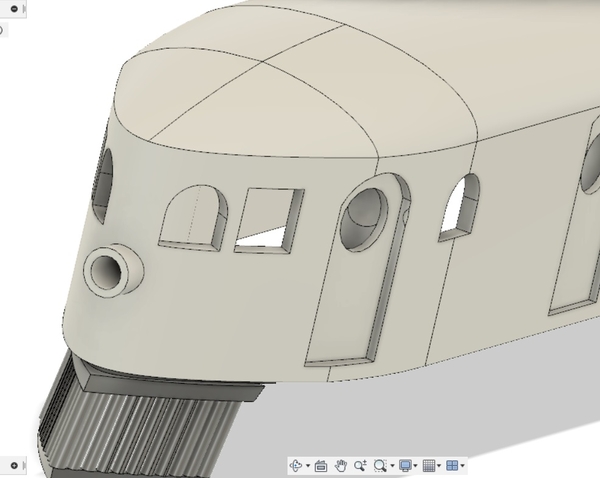

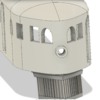

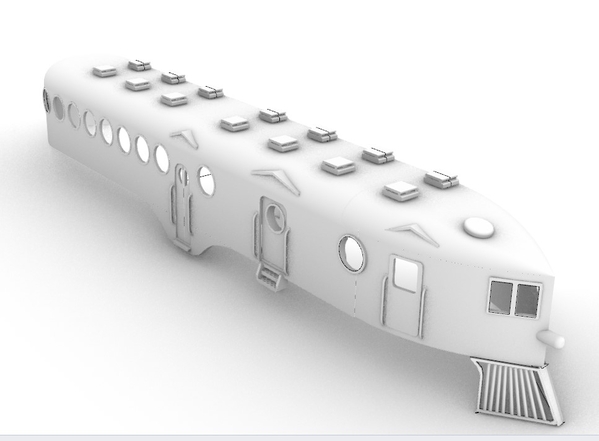

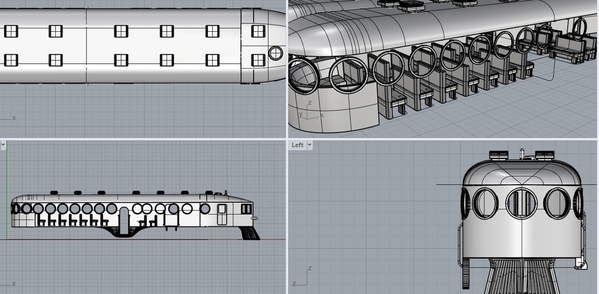

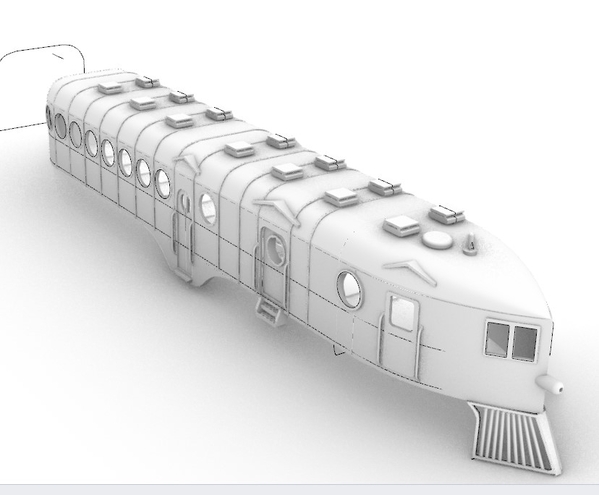

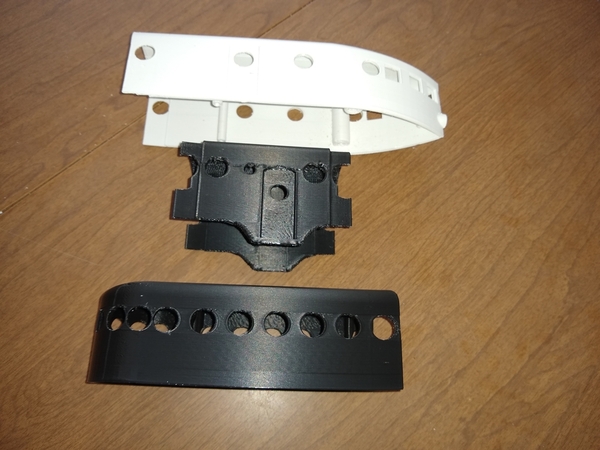

Here are the contents of each 72ft McKeen Car kit. There are 3 body sections, a power truck frame, two idler truck subframes, two pilots and a long-shanked coupler.

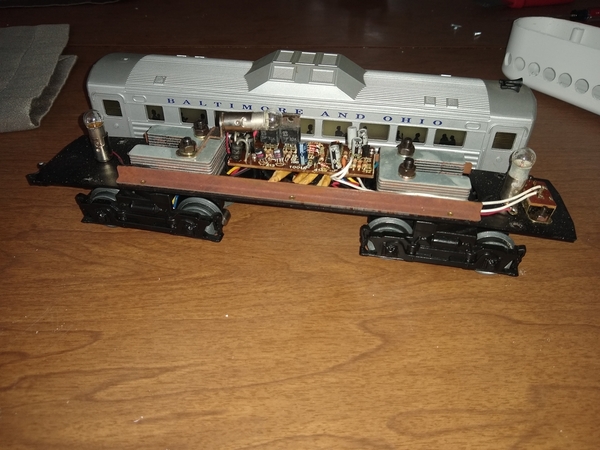

You can see how the body sections slide together. As I demonstrated in the prototype build, all of the screw bosses you see align with existing holes in the MTH Railking Doodlebug's frame for easy conversion.

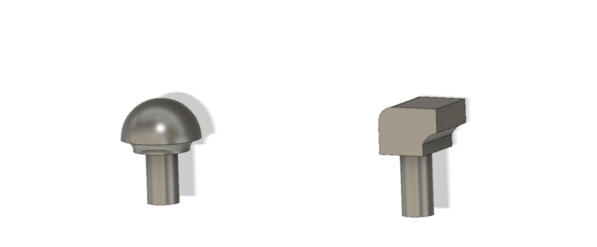

Each kit will ship with two pilots so you can choose which one suits your fancy.

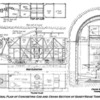

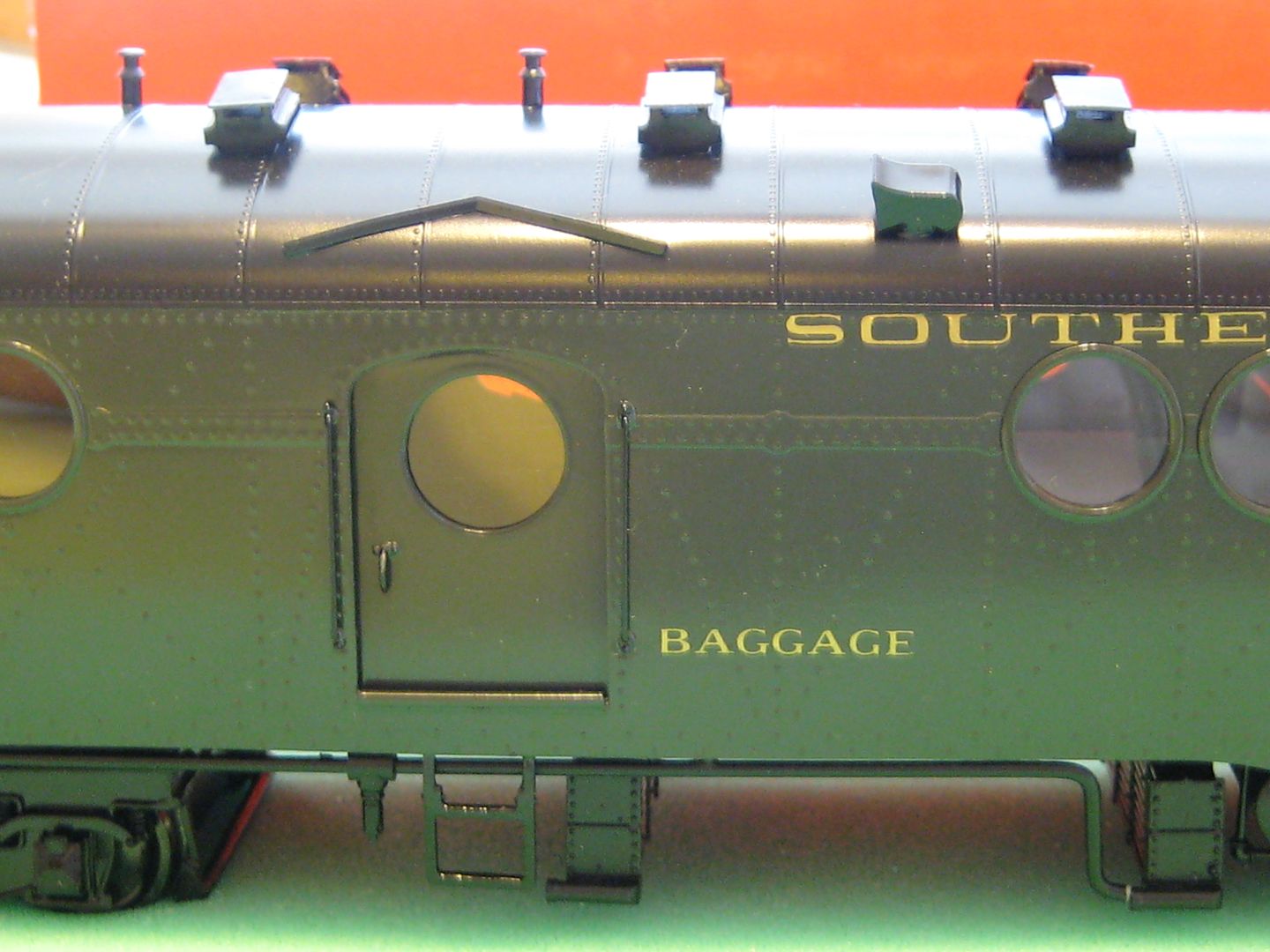

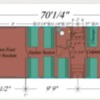

I am also offering the 40-foot mail car kits! Each kit contains 1 40' scale body, 4 opening doors and 1 hand-cut brass frame so you can mount the trucks and couplers of your choosing.

I will cut and install the door guide wires for you. These keep the doors from falling out or sliding around.

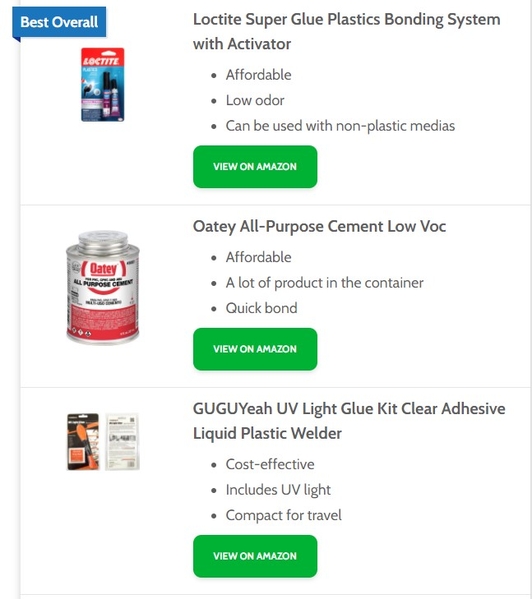

And now at long last, here's how you can get your very own McKeen!

What You Can Order

72-foot McKeen Car kit: $125 plus shipping

40-foot McKeen mail trailer kit: $75 plus shipping

72-foot McKeen Car and 40-foot mail trailer kits together: $200 with free shipping!

How To Order

I will be taking reservations for the next 7 days (from 1/28/22 to 2/4/22). Send me an email at the address on my OGR profile to make your reservation. Tell me which kit or kits you would like and give me your mailing address so I can calculate the postage. Each kit takes a solid 4 days of printer time so there will probably be a waiting list (I will try to estimate wait times as best I can). I will issue you an invoice when your order is complete and ready to ship.

I now have 1 McKeen kit and 1 trailer kit fully printed and enough material on hand to manufacture 2 additional McKeens, which should keep my printer whirring for another week and a half. I will order enough additional material to fulfill however many reservations I receive in the next week. Looking forward to fulfilling your decade-long quest for the O Scale McKeen!