Here's my report on the Beta 3.5

Roy Yost’s test of Menards Beta 3.5 Santa Fe diesel loco 2/3/2022

First off, let me say thank you for replacing my poorly built Beta 3.1 with this Beta 3.5. It cost me about $28 to ship the 3.1 back to you, but it could have been worth it. Let me explain.

The good:

The loco came to me in fine condition. The packaging materials are doing their job.

The firmware is working well. Speeding the loco, slowing the loco, and reversing the loco were smooth. I would still prefer the first speed step to be slower than it is. I run the loco at about 8 volts of track power. I like to run at medium and slow speeds.

The loco body ran smoothly and without all the shimmying and shaking of the 3.1 model. Both wheels on one axle are pressed on crooked and that truck did a mild hunting/yawing while running, but the loco body seemed to run true. More on this later.

The body mounting bolts were installed with reasonable force, not like the excessive force used on my 3.1.

The bad:

I still feel strongly that the gears press fit onto steel axles must be made of metal and not plastic. Two plastic gears must be changed to metal if the loco is to have a long and happy life. These are the driven worm wheel gears and the drive gear for the external idler gears. Due to the different expansion rates of the steel axle and the plastic gears, the gears that are press fit onto steel shafts will eventually split and will rotate/slip on the shaft. Since it seems unlikely that this will actually happen, I may have to lower my expectations. But I still feel that these plastic gears will come back to bite Menards eventually. For me, if these gears get into production, that will be a deal breaker and would prevent me from purchasing a production model.

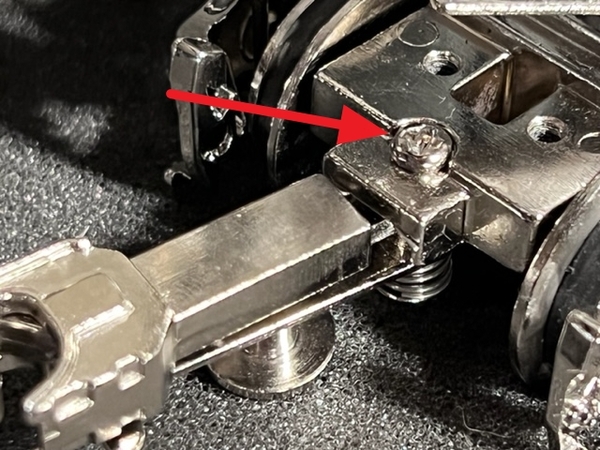

The couplers still sit a bit lower than standard. The “thumbtacks” on the couplers were not fully riveted and flopped around. The rear coupler was floppy, so I applied the same fix of coating the threads with fingernail polish to hold them and tightening the mounting screw almost tight.

The two non- traction tire wheels on the rear truck were both pressed on crooked. Running the loco upside down, they really looked bad. Fortunately they did not affect the loco operation as badly as it looked like they should. Maybe because they did not have tires, maybe because they were not gauged too wide? I tried to straighten the worst one, but the pressure required was greater than I was comfortable applying. I am wondering if the non-traction tire wheels are made with the center holes too small, so they must be pressed on with excessive force. There still seems to be no manufacturing fixtures to assure that the wheels are pressed on straight and to the proper gauge.

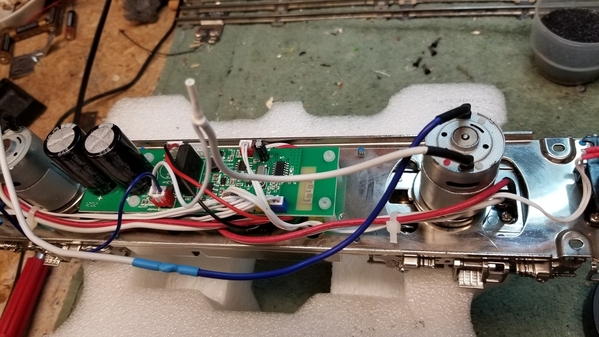

While there was grease on the external idler gears, there was no grease whatsoever on the brass worm gears on the motors. I do not know the various friction properties of brass and Nylon, but worm gears slide in operation and they require grease, in my opinion.

The really ugly:

I ran the loco on a freight train on my layout at medium/slow speed for about 45 minutes one night. The track is O-54 with no switches. The cars were mostly old wooden/metal kits from the 40’s and 50’s, all equipped with modern trucks made by Atlas. Everything ran smoothly and no odd noise or excessive heat was observed.

Here’s where it gets strange.

The next morning, I fired up the track at 8 volts again. I happened to be looking at the loco when I turned the remote throttle. There was a brief flash of light inside the cab, just for an instant. It was a cold white flash, like an LED and not a yellow flash like a spark. All the lights worked as they should. All the sounds worked like they should. But the loco would not move.

Taking the loco to the work bench for some tests revealed some surprises.

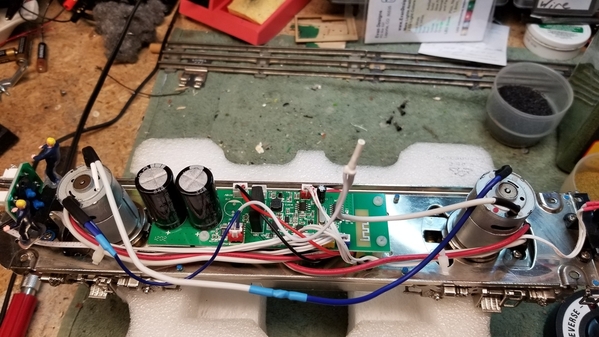

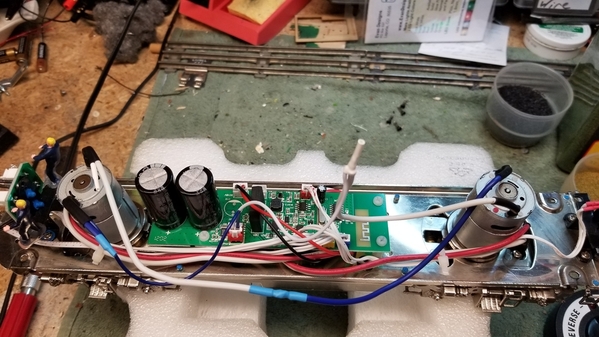

Examining the circuit board with a magnifying glass revealed no cold solder joints, no non-soldered solder joints, no burn marks, no loose components, no burnt components, no loose plugs, nothing. Everything looked good.

Unplugging the motor plug and running the motors on DC, the motors did not draw excessive current. I did not record the actual current, but it was about 90% of the current drawn by similar Williams motors that I tested at the same time.

This is where it really gets strange. I plugged an incandescent light bulb into the socket where the motor plug goes, so the board was only powering the bulb, not the motors. The bulb was off when the remote was in neutral position, and lit up when turning the throttle either forward or reverse. It seems as if the board is working, but will not handle the current of the motors – but these motors are not drawing excessive current. Very strange.

Conclusion:

So now my roster has a Beta 1 that is almost unusable because of the abrupt starts and stops. The roster also has a Beta 3.5 that does not run at all.

I have to admit that I am losing faith in the product. I cannot find the receipt for the Beta 1, but the Beta 3.1 was $201.77 and shipping it back was $28, so I am roughly $400 in the hole with nothing to show for it. I could put reverse units or bridge rectifiers in the locos and run them until the gears fail – and they will. When that happens, I could retrofit the locos with Williams motors and drive blocks, but that seems like a lot of work and additional expense.

I thought being a Beta tester would be fun, and I still like doing it, but I did not realize that it would be so expensive.

Regards

Roy Yost from the west coast