Greetings from the shores of Puget Sound

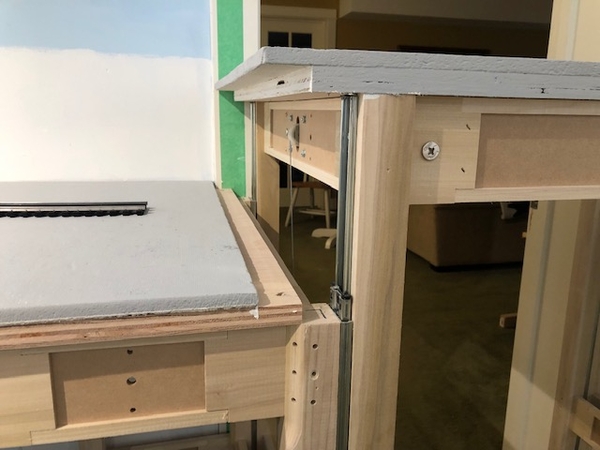

When you pull open the door to my train layout room, you immediately encounter my Mianne Liftgate

Installed and working well with the exception of the lower limit switch being a little finicky in adjustment. I believe a spring-loaded idler pulley will solve that issue. Gunrunner John wrote up a very simple and good solution a few years back.

Today I would love some suggestion on two issues regarding the liftgate

1. I will need to power 5 different sections of track so 1 common neutral and 5 hot for a total of 6 contacts. I am searching for solutions. some type of contacts when bridge is seated in lowered position or a hard connection cord that travels with the up and down of the lift (routing would be the issue here)

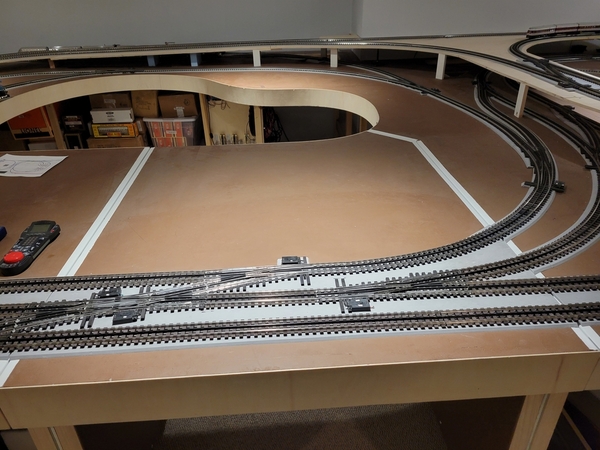

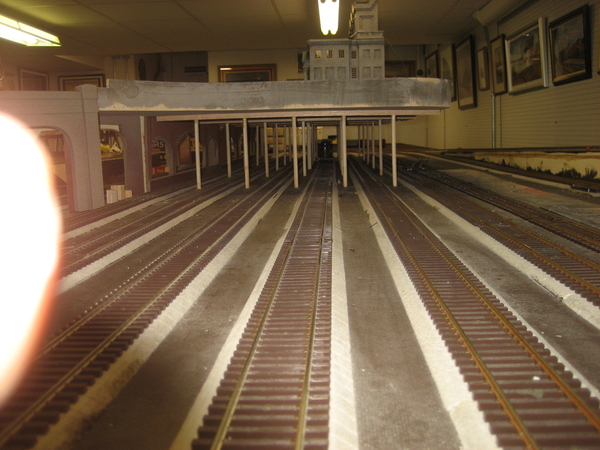

2. What is not built yet is a second (upper level) that will carry 4 mainline tracks on 3/4 ply and 1/2 Homasote 10" above the current Homasote deck painted gray. Does anyone have some good suggestions or photos of a second level construction framing detail (rigid without getting way to heavy or interring with alignment or view).

Thank you in advance for any comments or help, I finally got my train room back and have started the benchwork again.

kevin