With Christmas around the corner the kids are pestering me on something they can buy me. For those that use MM rollers, is three enough to start or should I have them order more??

Replies sorted oldest to newest

recommend 4 for a start...most loco's will use 4 some of the big steam might need more...joe

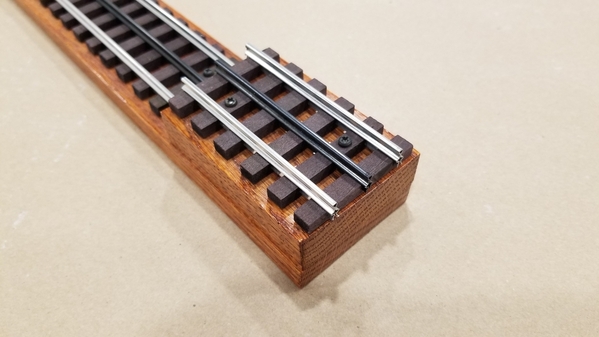

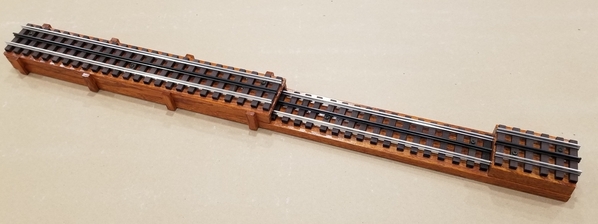

If you build a stand from wood and some spare/old track the package with 4 is enough even for articulateds. Just use a small 3/4" piece of wood under the pilot truck and you're good to go.

I like your sliding track section Joe, very tricky. ![]()

All of the rollers from Micro Mark comes with 4 sets of rollers to a package. One set has a pickup for the center rail. I bought one set and a year later, bought a second set. That way you'll have two pickups for the center rail. You will also be able to support all of the drivers.

Joe, would you be willing to share your design plans please?

They are sold as a set of four.

Bruce

I have found a set of 4 adequate for nearly everything. I don't have any articulateds.

On 6 axles diesels, I can put one at each end of the trucks. On 10 driver steamers, I just put them on the outer 2 sets at each end.

By the way, you don't have to set these on the track. I have a pair of wires from my track to my workbench with alligator clips on each wire. I can clip the alligator clips to the roller bases setting on my bench and run things that way. For 2 rail clip to each side, the bases are insulated, at least mine are. For 2 rail clip to one side and the center contact on the one.

I’d just go with one set and make a nice, small project with a base like the one Joe submits pictures of. I have two sets and it’s kind of a PITA to position them. YMMV

click photo to enlarge

Attachments

@Windy City posted:Joe, would you be willing to share your design plans please?

I don't have a design plan. It was made of scrap wood and some Gargraves track. The front elevated section is permanently attached to the base. The back portion can slide back and forth between the small vertical guides to accommodate different size locomotives. Here are some additional photos.

Attachments

Joe - Great design. How long did you make it??

If someone here decides to build one, and documents the construction step-by-step with a series of high-quality photos, he/she could submit it to the magazine and make an easy $200.

Jeff

It looks like about 3 feet.

Joe: ould you supply some dimension on yours please. How long is each section and the thickness I want to build one for me. Allan if I get what I need I amy take you up on the offer!

Bachmann/Williams is listing a 3rail "Rolling Road" that includes wheel cleaners for $159. Orders are being taken by Transworld for March 2021 delivery. Here is the link

Joe certainly has a winner there. Functional and looks like a piece of furniture. Mines on the crude side but functional. Built with 1x4’sand 1x2’s. Some rubber feet on the bottom. I don’t run large articulateds. Easily accommodates a 4-8-4. The front track adjusts to fit the pilot truck on shorter locos. The tender stays level with the engine. The aluminum angle just helps to support the side plates of the rollers. It’s just over 3 ft. Long.

Attachments

I'll measure mine up and post the dimensions either later tonight or tomorrow.

I have some. Don't like them. I have trouble with the locomotive's wobbling on them. Yes i put nuts on them. Didn't help.

Maybe I'm doing something wrong.

I just got a set of 4. Been wanting them for years.

@Trainlover9943 posted:I just got a set of 4. Been wanting them for years.

Just got my set as well!!

Sweet!

Mine is 36 inches long. Accommodates my largest locomotive (DM&IR Yellowstone) no problem. Only need 4 rollers as well.

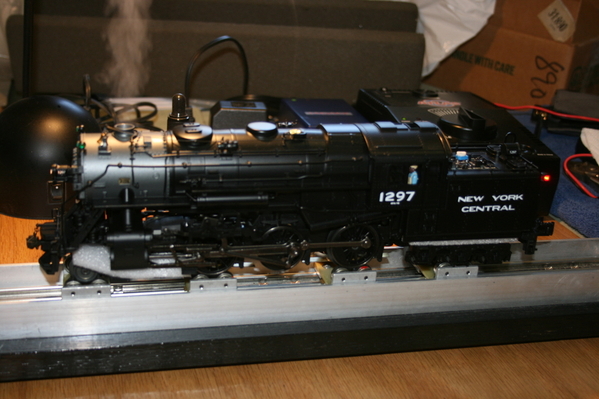

I built mine as a Display Stand - strictly for this engine only. If I were building a Test Stand I would have made the sliding pieces.

Rick S, I’ve never been big on large articulateds. Just need huge curves and long consists to look right. But that setup is Sweet. What a great display. I love the wheel slip feature. Even though they aren’t slipping. The sounds give you the illusion they are. I knew the engine had this feature. Just haven’t ever heard it.

Lionel should offer this in all their Legacy engines.

Awesome thread. I was thinking about getting rollers and new to the hobby. Seeing their value and utility here has solidified my thoughts.

@Dave_C posted:Rick S, I’ve never been big on large articulateds. Just need huge curves and long consists to look right. But that setup is Sweet. What a great display. I love the wheel slip feature. Even though they aren’t slipping. The sounds give you the illusion they are. I knew the engine had this feature. Just haven’t ever heard it.

Lionel should offer this in all their Legacy engines.

Thank you for the kind words Dave. I always wanted one but knew it would never fit on my 8' x 15' layout. I joined a local train club the other year and as I was helping set up one of the very gentle corner sections I thought, "I could run a Big Boy on here!" And the quest began. . . After I got one, I made that stand so I could run it at home. I have some videos of my "long consist" on my YouTube channel.

An easy way to do a display only stand is to suspend the locomotive about 1/16" above the rails using some flat head screws. I use this technique for my York Meet Super-Chuffer display stand. No rollers, and the screws with rubber tops are spaced to drop into a recess here and there so the engine is stable.

Here is some general information on how my base was constructed. This is a sliding type roller base which will accommodate any size locomotive. The base is constructed of a piece of wood measuring 2-1/2" wide by 1/2" thick and 30" long. At the front end, a small piece of wood is fixed to the base. This is for support of the leading truck. I then attached track to the base and end piece as shown.

The sliding portion was constructed of three separate pieces of wood to form a "C" channel. It is 16" long. Four fingers were glued to each side. This allows the sliding portion to be re-positioned while staying in alignment with the rest of the base.

Two screws are inserted under the sliding portion so they screwed into the track on top. The heads of the screws are left protruding enough so that when the sliding piece is placed on the base, the screw heads will also contact the rail heads on the base track. This allows me to connect power wires to only the base track or sliding track but allow both to be powered. When I use this roller base for testing, I just connect power wires to the exposed sliding track. If I use the base for display purposes, I connect the power wires to the base track, This way the wires are partially hidden under the sliding portion.

Here are some photos of the sliding portion in different positions. It really can handle just about any size locomotive. Of course the bigger the locomotive the more rollers you will need.

Attachments

Love your design Joe. What were the lumber dimensions you used? Off the shelf stuff or custom cut?

Most of the important dimensions are listed above.

You do not need to set the roller stands on track. I have used mine for years without that. I have a set of test leads with alligator clips routed onto my work desk. I use them when cleaning loco wheels. I put the loco in a cradle upside down and connect the leads to proper contacts to power it. Then I can run the wheels and clean them.

I also use the leads by connect them with the alligator clips to two of my roller stands setting on the work desk. Since the loco is not moving along, putting power to just one set of wheels does the job just fine. I connect the leads to roller stands and I can run the loco on the bench for whatever needs I have.

I have found that the roller stands are much more stable setting on the bench than setting on section of track. Setting on the track raises them another half inch. I don't want a loco to tumble over while on the rollers.

Joe's design is handsome for a test track, but Rick's whole set up takes the cake for sexiness. it makes me want to go out and buy a big engine just for display.

But for economy and simplicity you could just do something like John does. Or even with a set up like Joe's, couldn't you eliminate the rollers all together and have some metal bars in the dropped down center section that contact the rollers and hold the weight of the engine but the drivers would run free? Maybe to tippy? The tender, pilot and trailing truck would still be on the upper level.

I want to hear more about what John does- where does he put the screws?

@Will posted:I want to hear more about what John does- where does he put the screws?

My display stand was customized for the engine I was using, so I put the screws where the head would drop into a screw recess in the locomotive frame. That makes it sit very stable and just suspends it slightly above the rail.

@gunrunnerjohn posted:My display stand was customized for the engine I was using, so I put the screws where the head would drop into a screw recess in the locomotive frame. That makes it sit very stable and just suspends it slightly above the rail.

Very clever. So the rollers and pilot wheels and tender still contact the track, I assume, providing power?

Yep, I just suspended the drivers about 1/16" above the track, everything else sits directly on the track. Since the tender is still hooked to the locomotive, everything is stable and even if you bump the stand, nothing moves. I used to have issues with knocking the display engine off the rollers when I had it up on rollers. I got the idea of suspending it on the screws from other displays in the Orange Hall at York. Some of the large scale guys had stuff suspended like that and it looked really cool and worked well.

I did what John suggested when I posted this video a week or so ago. Works great.

https://ogrforum.ogaugerr.com/...3#153603996847757973

John

@PRRronbh posted:

I like you're roller stand. Did you build it ?

@feet posted:I like you're roller stand. Did you build it ?

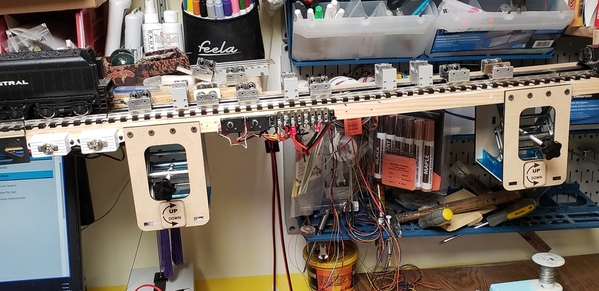

Yes, designed it so could test anything I own including AA units Centipede.

In the first pic the S1 is sitting on a length of RealTrax that includes an operating section. That why can rolling stock couplers and any operating cars. Also as pictured can set the engine(s) there and then space the rollers and support track sections where would need them. Then built the shorter (18-inch) test stand to make it easier to test single unit diesels and short steam engines. All in all think have 12 rollers.

Ron

For those who built stands with Micro-mark rollers on track, did you have issues with the pickup block "rocking" on the center rail due to the screw holding the pickup shoe being slightly too proud? This is the case with the set I just received (whether I mount it on O or O27 tubular, don't have nay other track to try it on).

Here's the version I built for my S-gauge locos. Similar in concept to what others have shown, except that I don't need a center rail pick-up, so it was easier to remount the rollers on wooden stands, which makes for a much more solid operation. Here's the link to my previous post about a year ago:

https://ogrforum.ogaugerr.com/...c/131926382613123531

- Rich

@S Rice posted:For those who built stands with Micro-mark rollers on track, did you have issues with the pickup block "rocking" on the center rail due to the screw holding the pickup shoe being slightly too proud? This is the case with the set I just received (whether I mount it on O or O27 tubular, don't have nay other track to try it on).

I've got that issue on tubular. Most stuff is heavy enough it doesn't matter but I'll eventually change that screw.

@Ahitpy posted:Bachmann/Williams is listing a 3rail "Rolling Road" that includes wheel cleaners for $159. Orders are being taken by Transworld for March 2021 delivery. Here is the link

Did I miss it or are these still on the way (going on two years late?)?

WILLIAMS #39031 ROLLERS AND DRIVE WHEEL CLEANERS (O SCALE 3-RAIL).

WILLIAMS #39030 ROLLING ROAD W/ROLLERS AND DRIVE WHEEL CLEANERS (O SCALE 3 RAIL)

Here's a current link: Williams #39031 Rollers and Drive Wheel Cleaners (O Scale 3-Rail), but now they're only $89.99. ![]()

Reminds me of the joke... something like....

Customer says to clerk: "Your price is $100 and your competitor's price is only $90. Unfortunately he is out of stock."

Clerk to customer: "No problem, we beat their prices all the time. When we are out of stock, our price is only $80."

@S Rice posted:For those who built stands with Micro-mark rollers on track, did you have issues with the pickup block "rocking" on the center rail due to the screw holding the pickup shoe being slightly too proud? This is the case with the set I just received (whether I mount it on O or O27 tubular, don't have nay other track to try it on).

I'm late to this topic. If I need to start a new one, someone let me know and I will. I have the same question as Rich posted because I just built a test track with a sliding pilot bed from MartyE's tips on You Tube. Has anyone come up with any modifications to the Micro Mark rollers that allows them to position their engines more evenly by replacing the screws? Also, has anyone tried the Proses rollers and how do they compare to Micro Mark's? I've only tried one engine on my test track and it's a lighter Railking SD60 diesel engine. I got it to work using the 4 roller set but it did not work until I set the roller set with the center rail bar underneath the fake wheel pair where the pick-up roller was, and then was able to use an added pair working wheels on an additional set of rollers. But the engine doesn't sit evenly. Seems like there's got to be some easy modifications to make the rollers work better on tubular track.

Mike

@IRON HORSE posted:I'm late to this topic. If I need to start a new one, someone let me know and I will. I have the same question as Rich posted because I just build a test track with a sliding pilot bed from MartyE's tips on You Tube. Has anyone come up with any modifications to the Micro Mark rollers that allows them to sit their engines more evenly by replacing the screws? Also, has anyone tried the Proses rollers and how do they compare to Micro Mark's? I've only tried one engine on my test track and it's a lighter Railking SD60 diesel engine. I got it to work using the 4 roller set but it did not work I until set the roller set with the center rail bar underneath the fake wheel pair where the pick up roller was and another pair working wheels on a set of rollers. But the engine then doesn't sit evenly. Seems like there's got to be some easy modifications to make the rollers work better on tubular track.

Mike

I don't like their rollers. I added the nuts as recommended but the engine I test run wobbled to the point I was afraid it would fall off.

I had no issues with them not sitting on the track properly or powering the engine.

I think I figured this out, but welcome feedback/comments. First, the brass contact sticks pretty far out, which will make the center contact roller set not seat flush with all 3 rails. Second, the screw is too tall by almost 1/16 inch, which creates the same issue of not seating flush across the 3 rails. You can see by the photo, the hotel room key card as a straight edge shows the screw head sticks up too far. So, the solution is to bend the brass contact more even with the bottom of the roller housing and then to grind the screw head down using a dremel tool to eliminate the high spot, making the whole roller set seat flush across all 3 rails.

Mike

Attachments

@IRON HORSE posted:So, the solution is to bend the brass contact more even with the bottom of the roller housing and then to grind the screw head down using a dremel tool to eliminate the high spot, making the whole roller set seat flush across all 3 rails.

Actually, that's not an ideal solution. The problem is that the brass contact needs to have some spring left so it makes good contact with the center rail.

@gunrunnerjohn posted:Actually, that's not an ideal solution. The problem is that the brass contact needs to have some spring left so it makes good contact with the center rail.

GRJ,

Yes, I misstated that. By "more even" I meant to take some of the spring lift off, but not all of it, so that the brass still makes good contact. So I did that and grounded the screw down and the center rail roller set is way more stable for setting engines in place. And it works great, especially on lighter Rail King engines, as they now sit flush across the track.

Micromark sends these roller sets with the brass bent up too far, making the center rail roller set rock back and forth while the other roller sets sit nice and flush. And the center screw holding the brass contact is too thick, but grinding it down solves the problem.

Mike

Attachments

I never liked the Micromark rollers, they only have one with the center roller contact. I bought a set of unknown origin that had roller contacts on all four pieces! I have a couple of sets of the JAK rollers that have two sets with roller contacts, that seemed reasonable.

the section of track where the engine sits can be raised or lowered to accommodate the roller-test section.

the tender can remain attached to the engine being at the same track/roller height.

the rollers come in various heights above the track.