18 or 21 volts max to the track (AC or DC I suppose) are the 2 voltages usually mentioned when talking about O scale trains. I think most can motors in the engines are 12vdc types. What's the maximum voltage that actually gets to the motor(s)?

Replies sorted oldest to newest

220v, 221v, whatever it takes.

Sorry, couldn't resist.

Chris Sheldon

Bob,

I hope one of the experts jump in. Per all the forum discussion on chopped and rms (root mean square) sine waves, the numbers you mention are "effective" values. An estimate for the peak of the ac wave would be for example (square root of two)*18 volts. This would not be an effective value, but would be the highest voltage on the wave, which is what I think you are looking for. 120v house voltage is the effective value, the peak of the sine wave is 120*1.414 or around 170v.

I will look for one of those other threads, they had scope pictures, I think GRJ did several of them.

The motors don't see any of the track voltages directly. They're driven by the reverse board in conventional or the motor driver in command operation. Typically, you'll see fairly low voltages on the motors, at full throttle on the bench I've seen 11-12 volts on some, that's a maximum. That would be track jumping speed, normal operations will be in the 4-7 volt range with a typical locomotive. A decent can drive motor will turn with no load at below 1.5 volts.

Forget all this for the AC Pulmore motors. ![]()

Thanks John.

As you know I use batteries in all my engines, but I have 2-3 that, even with a 12v battery inside, just don't go as fast as they did under TMCC or DCS. They go plenty fast for my purposes, but I can't figure out why they are slower than before.

My Williams brass N&W 611 for example. Using PS2 it was plenty fast, too fast actually, but using a 11.1v (not 9.6v) battery it barely got up to 48mph. Last night I swapped out the 11.1v (not 9.6v) for a 12v pack and gained 6 more mph to 54mph, still below what the engine did using PS2. I have 2 others that are even slower at top end, but they still use the 9.6v battery. One is a Lionel 4-8-2 and the other is a 3rd Rail E7, I plan on putting a 12v battery in the E7 but might not be able to do it in the 4-8-2 (limited room in the Vanderbilt tender I built).

I'll have to ask on the Freerails forum, maybe the Deltang receiver is using up some of that voltage.

I also have an Atlas F3 and GP9. The GP9 is twice as fast as the F3 and I think they have the same motor/gearing/trucks. I may have one wired in series and the other wired in parallel, need to check. The GP9 clocks in at 100+mph!!!

Well, the input voltage is going to be cut down by the electronics, so if you only start with 9.6 volts, you'll get less voltage at full throttle on the motor. Also, remember that if you were supplying AC, you typically get a boost in the DC voltage available to the electronics as the filter caps charge to the peaks of the AC voltage.

Since I have no experience with battery operation, and also know nothing about the actual electronics in use, I can't really comment in detail on why the locomotives are obviously not getting as much voltage/power to the motors.

@Bob Delbridge a lot has to do with the gear ratios. If you don't mind, I would love to know what the gear ratios are on your Lionel 4-8-2, Atlas F3 and Williams J. You can determine this without hurting the loco, by turning the flywheel by hand, and counting the number of turns it takes for one revolution of the driving wheels. (Make a small mark with a pencil or marker on each.)

Sometimes if you know the make and model number of the motor, you can find the "no load RPM" listed. The in-service speed will be about 80-85% of that at the rated voltage. So if you know the motor and you know the gear ratio, you can figure out how fast your locos will go. What I've found is that 90% of 3-rail locos are geared way too fast! There's almost no reason for a model train to go more than 65 scale mph on a typical home layout. Even 45 mph looks pretty fast from an on-board or trackside camera.

Thanks for sharing, and I would love to hear more!

Ted S posted:@Bob Delbridge a lot has to do with the gear ratios.

Since the gear ratio didn't change between the TMCC electronics and the battery electronics, I don't think the particular issue being discussed is likely to be due to gear ratios. ![]()

Fixed a mistake in my post...the 4-8-4 611 had an 11.1v LiPo battery pack installed, not 9.6v, but changing it to a 12v did up the speed from 48mph to 54mph.

Most of my other engines use a 9.6v battery and run fine.

Ted S, I agree with the comments you made about top speed, 45 (maybe 60 for a fast passenger engine) is fast enough on a home layout.

Although the gearing didn't change, the 3 engines in question are the smoothest running engines I have at low/slow speed. I think the gear ratio in the Williams 4-8-4 was around 40:1 last time I checked.

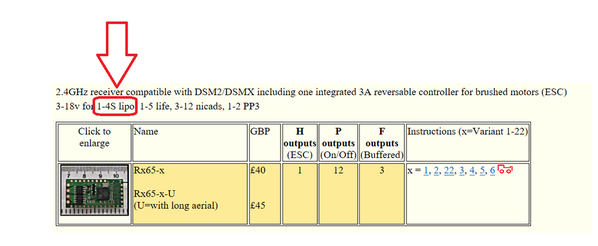

The voltage used by the Deltang receiver has to be low, it's such a small package there's no large components on the board.

I want to say that 12 volts, whether it's from a transformer or battery, is the same but I really don't know for sure.

I could put a larger battery in the 4-8-4 with that huge tender, but I see no need. I think the motor in the 4-8-4 is the same as in the other Williams engines I have (two 2-8-2 and two 4-6-2). The 3rd Rail E7 has a big 12v Canon motor while the others are MTH and Atlas and all have a smaller motor(s) in them.

@Bob Delbridge If the 'J' is really geared at 40:1, a scale speed of 54 mph is the most you can expect, unless you want to drive the motor above its nominal 12-volt rating. Here's the math:

Mabuchi RS-555 motor rated for 12,000 RPM at 12 volts. 85% of that is 10,200 RPM with a typical train load. 10,200 motor RPM / 40:1 = 255 driving wheel RPM. 70" drivers times 3.14 (Pi), times 255 = about 56,000 scale inches per minute, or 3.3 million scale inches per hour. Divide that number by 12 inches/ft = 280,000 scale feet per hour, and divide by 5280 ft/mile = 53 scale MPH. IMO plenty fast on a smaller layout. Overdriving the motor at 15 volts probably won't hurt anything, and would get you close to a passenger track speed of 60 mph.

You might find that your Mikado is geared around 25:1 with smaller driving wheels in the neighborhood of 63 scale inches. So ironically it would be a little faster. So what motor is in the Lionel 4-8-2, and what's the gear ratio??

I recall that in the early 1990s, Andy Edelman (now with MTH) had an "upgrade" service for Northerns, where he replaced the stock Mabuchi motor with a Pittman, and also swapped the gearbox to the one used in the Mikado, I think. (Both of these locos were imported from Samhongsa and had a similar design.) The net result was a faster-running Northern that drew less current, because the Mabuchi motors were current hogs, especially at higher RPM. I couldn't afford Williams brass at then-current prices, but if I did I'm pretty sure I would have left mine stock! Unfortunately the "faster is better" mentality took root at MTH, consequently none of their first-generation locos ran as well as the original Williams and Weaver brass, until the band-aid of speed control was applied circa 2000. The rest, as they say, is history!

Thanks Ted!!!

Yeah, the 54mph speed (measured at 90% throttle) of the 4-8-4 is fine, I think your 25:1 on the Mike is correct (from memory). Not sure what the Lionel 4-8-2 is but I'll try to remember to check next time I work on it.

I'm pleased with all my battery-powered engines, just curious as to why a few were slower than what I was getting when using TMCC or DCS.

But there is a big difference between 12 volts and 9.6 volts. Maybe that's all it is that I'm seeing in these comparisons. That's 20% less voltage. Doesn't explain why the 4-8-4 was so slow (48mph) when using the 11.1 volt LiPo pack though.

I'm really surprised at how well my RailKing USRA 0-6-0 runs at slow speed, the gearing lets it crawl. Even the Weaver 4-6-0 I got from Ed Rappe is a great moving engine at low speed.

I have two RailKing 2-8-0, one has a 9.6v battery the other has an 11.1v. The oldest one (11.1) has a top speed of 70mph at 80% throttle and the newer one (9.6) has a top speed of only 55mph at 80% throttle. Both are faster than what I would run a 2-8-0, easy enough to back the throttle down.

Other than the 4-8-4 (now 12v NiMh), the 3 engines currently using the 11.1 LiPo pack are the faster group of engines.

Bob Delbridge posted:Fixed a mistake in my post...the 4-8-4 611 had an 11.1v LiPo battery pack installed, not 9.6v, but changing it to a 12v did up the speed from 48mph to 54mph.

Most of my other engines use a 9.6v battery and run fine.

....

I could put a larger battery in the 4-8-4 with that huge tender, but I see no need. I think the motor in the 4-8-4 is the same as in the other Williams engines I have (two 2-8-2 and two 4-6-2). The 3rd Rail E7 has a big 12v Canon motor while the others are MTH and Atlas and all have a smaller motor(s) in them.

O-gauge engines use a bridge-rectifier to convert the AC-to-DC. Even if you apply DC (e.g., from a battery), the bridge rectifier is still in-circuit and drops the battery voltage by 1.5-2V. So using your 11.1V battery, the DC motor will see, at most, around 9-10V DC. The 6 smPH increase by upping the battery voltage by 0.9V (11.1 to 12) is a reasonable estimate for additional speed you'd get by additionally increasing the battery voltage. In other words 6 sMPH/0.9V = 6.6 sMPH/Volt.

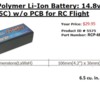

It appears you have a 3-cell LiPo pack or 3 x 3.7V = 11.1V. If you can find a 4-cell LiPo pack (14.8V) you'd have an additional 3.7V and your top speed would go up by 24 sMPH (or so).

There is no such thing as a 12V motor per se. A motor is just a bunch of wire, magnets, and metal. It's just that a "12V motor" happens to operate with practical characteristics (RPM, Torque, etc.) when driven by 12V. There is plenty of operational capability at other than 12V.

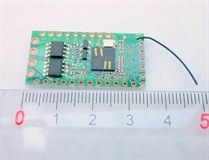

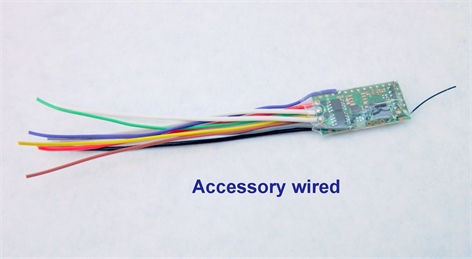

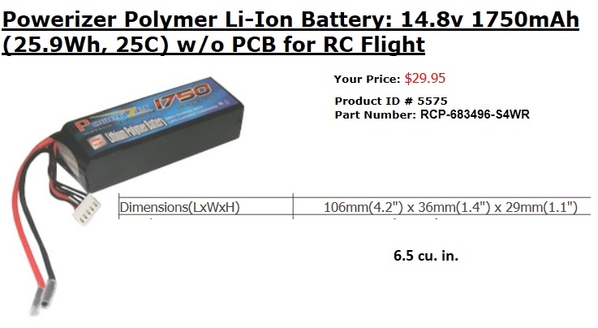

Stan, I don't think there's any large bridge rectifier in my circuitry. I'm using a Deltang Rx65b receiver:

One of those components may be a BR, but I have no idea. The board is 35mm long. All TMCC/PS2 guts have been removed.

Attachments

OK. I misunderstood what you have when I saw your initial comment about AC voltage.

You are correct. Your board does NOT have a bridge rectifier. The maximum voltage your DC motor will "see" is essentially your battery voltage...less 0.1V or so. What that board is doing is rapidly pulsing the DC motor with the full battery voltage. By adjusting the ratio of the on-time to the off-time (based on your remote control throttle setting), the effective motor voltage is controlled and hence the speed.

But the "math" is the same. By going from a 3S lipo (11.1V) to a 4S lipo (14.8V), you will up your max speed by over 20 sMPH.

Attachments

I agree. I don't think 14.8v would have an adverse effect on the motor, but getting a 14.8v battery to fit may be the issue.

I have 2 types of 9.6v NiMh batteries. One is approx. 1-1/8"x1-1/8"x4" long, the other is 1/2"x2-3/8"x4" long. The 11.1v LiPo is 7/8"x1-1/2"x4-1/8" long. The 12v NiMh is1-1/4"x2"x2-7/8" long.

I should get 2 of the 12v batteries tomorrow (Amazon Prime is QUICK!) and 1 will go into the 3rd Rail E7. I already have checked for space and removed the 9.6v battery (will use for another conversion soon). Should know tomorrow or Wednesday if the12v battery enhances the E7 performance.

Bob Delbridge posted:I agree. I don't think 14.8v would have an adverse effect on the motor, but getting a 14.8v battery to fit may be the issue.

I have 2 types of 9.6v NiMh batteries. One is approx. 1-1/8"x1-1/8"x4" long, the other is 1/2"x2-3/8"x4" long. The 11.1v LiPo is 7/8"x1-1/2"x4-1/8" long. The 12v NiMh is1-1/4"x2"x2-7/8" long.

What are the mA-Hr or Amp-Hr ratings for the different battery packs?

9.6V NiMH #1: 5.0 cu. in.

9.6V NiMH #2: 4.8 cu. in.

11.1V LiPo: 5.4 cu. in.

12V NiMH: 7.2 cu. in.

It comes down to stored energy which is related to Voltage x mA-Hr. Going from 11.1V to a 14.8V LiPo pack (of same size) may have a lower mA-Hr rating...but the product of Voltage x mA-Hr should remain the same - in theory. In practice the packs are no doubt built using a standard-sized 3.7V cell (3 or 4 in Series or Stacked - hence the terminology 3S or 4S) so there will be limited options on size.

As an aside, some might find it curious that if you open a 9V battery, you might find 6 1.5V AAAA (quadruple-A) batteries stacked.

Likewise, many/most NiMH packs are some number of 1.2V standard-sized (AAA, AA, C, etc.) NiMH cells stacked together. 8 cells x 1.2V = 9.6V. 10 cells x 1.2V = 12V. Etc.

In any event, to increase the top speed you must increase the available battery voltage.

Attachments

All NiMh are 2000mah, all LiPo are 2200mah, I’m getting 2-1/2 hours of run time on a charge.

Some back-of-envelope doodling to make sure the numbers add up:

9.6V NiMH #1: 19.2 Wh / 5.0 cu. in. = 3.8 Wh / cu. in.

9.6V NiMH #2: 19.2 Wh / 4.8 cu. in. = 4.0 Wh / cu. in.

11.1V LiPo: 24.4 Wh / 5.4 cu. in. = 4.5 Wh / cu. in.

12V NiMH: 24 Wh / 7.2 cu. in. = 3.3 Wh / cu. in.

Example: 19.2 Wh and 2.5 Hrs of run time, average power consumption only 7.7 Watts. So must be a lot of stopping.

A web search found this 14.8V with a slightly lower mA-Hr rating but similar energy (25.9 Wh) as your other packs of similar size (6.5 cu. in.). As long as the Wh rating is the same between batteries the run-time should be the same for the same average power consumption. It's just that with a 14.8V pack you'll be able to reach higher speeds. I have no idea if this would fit your application but suggests a solution might be out there.

Attachments

Thanks Stan! That Li-Ion battery may be the thing to use in Lionel 4-8-2 as it looks like it will fit inside the Vanderbilt tender and give me 5 more volts to play with.

Installing the 12v battery in the 3rd Rail E7 did what I wanted, the top speed at 90% throttle went from 48mph to 60mph.

This engine has always made some unusual noise, I had to replace part of the universal joint last night for the 2nd time, I think it might have been rubbing against the weights in the fuel tank so I removed them. I'll see how long this one lasts.

Who needs a sound card when you have a belt drive that sounds like a turbine at upper speeds ![]()